AlGaN deep-UV LEDs: Less is more

A Japanese collaboration has demonstrated that it should be possible to produce high-quality deep-UV LEDs with minimal MOCVD growth, using face-to-face annealed templates.

This work by researchers from Mie University, Tohuku University and the University of Tsukuba offers a promising approach to lowering the cost of production for deep-UV LEDs.

The team’s latest effort builds on its previous work, involving the development of high-quality templates with dislocation densities of less than 108 cm-2, produced via face-to-face annealing of sputter-deposited AlN. UVC LEDs produced on these templates and emitting at 263 nm have an external quantum efficiency of 8 percent.

According to the team, this is a record for external quantum efficiency – and it should be attributed to the switch from conventional MOCVD-grown AlN templates to those produced by face-to-face annealing of sputter-deposited AlN.

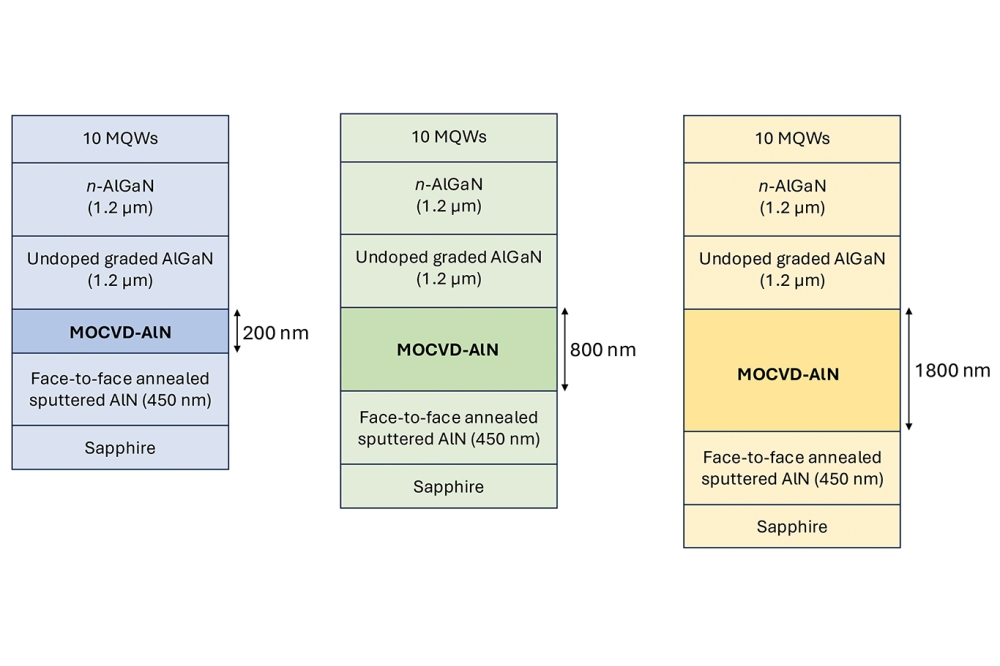

Initial work by the researchers employed MOCVD-grown AlN with a thickness of just 200 nm on the novel templates. The latest effort has considered the impact of thicker layers, which could lead to a reduction in dislocation densities within the device and ultimately a higher internal quantum efficiency.

For this investigation the researchers used three 450 µm-thick AlN films, created by RF sputtering on c-plane sapphire with a 2 ° off-cut relative to the m-axis. These films were annealed for three hours at 1700 °C, under nitrogen gas with a face-to-face configuration.

Using MOCVD, the team deposited an 800 nm-thick AlN layer on one of these samples and added an 1800 nm-thick layer of AlN on another. To provide a benchmark, they decided not to grow any AlN on their third sample.

Following storage under nitrogen, all three samples were placed in an MOCVD chamber, used to grow an epistructure featuring an active region with ten 2 nm-thick Al0.69Ga0.31N quantum wells sandwiched between 3.6 nm-thick Al0.44Ga0.56N barriers (see figure for details of the structure).

Drawing on information provided by X-ray rocking curves, the team determined that the increase in AlN thickness led to an increase in the edge-type dislocation density from 3.5 x 108 cm-2 to 6.4 x 108 cm-2. Screw-dislocations are far less prevalent, with a density of just 1.6 x 106 cm-2.

Scrutinising samples with cross-sectional scanning transmission microscopy confirmed results obtained X-ray rocking curves, with an increase in the thickness of AlN from 200 nm to 2000 nm causing the density of edge-type dislocations to increase from 2.1 x 108 cm-2 to 6.4 x 108 cm-2.

To investigate point defects, the researchers turned to the positron annihilation method. This approach determined that the type and the concentration of vacancy-type defects, at least in the upper part of n-type AlGaN, is identical for different thicknesses of AlN.

Plots of photoluminescence efficiency are similar for all three samples, indicating that changes to the thickness of AlN only have a slight impact on emission characteristics.

To try and uncover any differences in internal quantum efficiency between the samples, the team employed time-resolved photoluminescence measurements. This study found long lifetimes of over 2 ns under weak excitation, a result comparable to that for quantum wells on AlN substrates, highlighting the high quality of all three samples. Efforts also determined that the internal quantum efficiency is the same in all three samples.

Based on their findings, the team concluded that when employing face-to-face annealed templates, it’s possible to produce high-quality quantum wells on MOCVD-grown AlN with a thickness of just 200 nm.

Reference

R. Akaike et al. Appl. Phys Express 18 065503 (2025)