Red InGaN microLEDs: Boosting efficiency with all-ITO contacts

Engineers from King Abdullah University of Science and Technology (KAUST), Saudi Arabia, have substantially increased the performance of their microLEDs by using ITO for all the contacts.

By retaining the p-type ITO electrode and using this oxide for the n-type electrode and p-contact in their red-emitting InGaN devices, the team have increased external quantum efficiency by 60 percent and wall-plug efficiency by 50 percent.

These gains could aid the development of full-colour GaN-based microLED displays, which are promising candidates for augmented- and virtual-reality headsets, smartphones and watches.

Red LEDs that are based on InGaN are far less efficient than their blue cousins, due to the increase in indium content in the quantum wells that introduces substantial strain and crystal imperfection. Due to these drawbacks, it is paramount to optimise the light extraction efficiency of these emitters.

Light generated within an LED can fail to exit the device due to absorption, total internal reflection and shading from opaque electrodes.

It is well known that metallic p-electrodes, typically positioned on the top surface, significantly block light extraction. Previously, the team from KAUST addressed this weakness in red and green microLEDs, without compromising electrical performance, by replacing metal p-type electrodes with those made from ITO. This switch increased light extraction efficiency, light output power, external quantum efficiency and wall-plug efficiency.

Now the team has turned its attention to n-type electrodes and p-contact pads – positioned around the periphery of the active mesa region, they enable contact probing and effective current injection.

As light can be reflected within the device, the n-type electrodes and p-contact pads can lead to absorption or additional reflection, and ultimately reduce the light extraction efficiency. One option to address these losses is to replace the metal n-type electrodes and p-contact pads with transparent ones based on ITO.

To quantify the benefits of n-type electrodes and p-contact pads made from ITO, the researchers from KAUST have compared the performance of two forms of red-emitting microLED: one that combines p-type ITO with metallic n-type electrodes and p-contact pads; and another that employs ITO for all contacts.

Both forms of microLED were produced by growing an epitaxial structure on a patterned sapphire substrate by MOCVD. Devices were produced from the epiwafer with a number of steps that include photolithography and etching to define mesas, passivation through the addition of SiO2 on the sidewalls, and the deposition of ITO by electron-beam deposition.

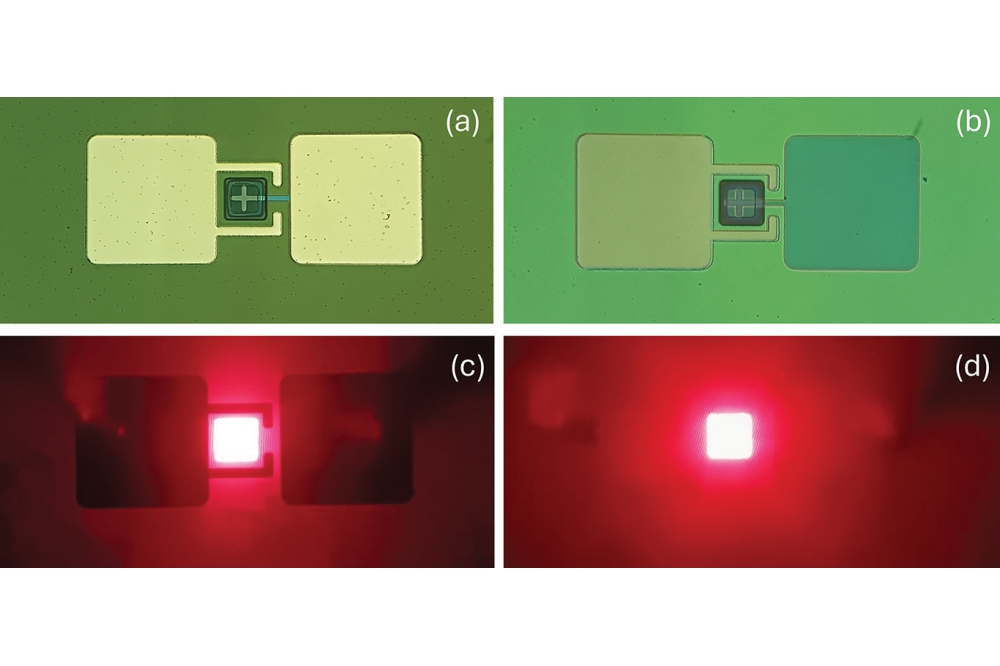

Electroluminescence imaging reveals that the ITO electrodes enable higher light extraction in the electrode region, with metal contacts significantly blocking the emitted light (see figure).

The emission from the all-ITO LED has a peak in its electroluminescence at 653 nm at a drive current density of 1 A cm-2, compared with 648 nm for the variant that incorporates metal contacts. The team attributes this slight difference to fluctuations in indium composition.

At first glance, the wavelength of these microLEDs appears to be longer than that required in colour displays, given that the red sources employed in high-definition TVs and augmented-reality displays have a dominant wavelength of around 610 nm, and red LEDs for ultra-high-definition TVs and virtual-reality headsets have a dominant wavelength of around 630 nm. However, according to KAUST spokesman Kazuhiro Ohkawa, the team’s all-ITO red microLEDs with a 653 nm peak wavelength have a full-width at half maximum of 53 nm and a dominant wavelength of 630 nm.

“If you look in other literature, you will find so-called red LEDs with peak wavelengths around 600-620 nm or less,” explains Ohkawa. “Their colour appears orange to the human eye. Our LEDs are true red.”

According to on wafer-measurements, peak external quantum efficiency with the all-ITO microLED is 2.1 percent, and maximum wall-plug efficiency hits 1.7 percent. Packaging these LEDs and measuring their output with an integrating sphere would lead to higher values for these key metrics, says Ohkawa. “The peak absolute external quantum efficiency and wall-plug efficiency of our red LEDs with packaging are expected to be 7 percent and 6 percent, respectively.”

Pictured above: Comparing the optical microscope images, (a) and (b), with the light emission images (c) and (d), highlights the benefits of using ITO for all the contacts of a microLED.

Reference

C. Altinkaya et al. Appl. Phys. Express 18 061001 (2025)