FBH develops diode laser module for additive manufacturing

FBH scientists, together with their industrial partners, have made progress in direct-diode Additive Manufacturing (AM) laser modules that can be used to melt aluminium.

The modules were tailored to address shortcomings in existing fibre or YAG-laser systems, which have a large footprint and require a fibre to deliver the laser power to the work surface, which is failure-prone.

The advances were reported at the CLEO/Europe conference and Laser World of Photonics trade show in Munich this year.

The FBH team presented a compact, continuous-wave 1 kW direct-diode process head, operating at 780 nm, the wavelength at which aluminium has an absorption maximum. The system incorporates highly efficient GaAs-based diode lasers with very wide apertures, so that they emit high per-chip powers.

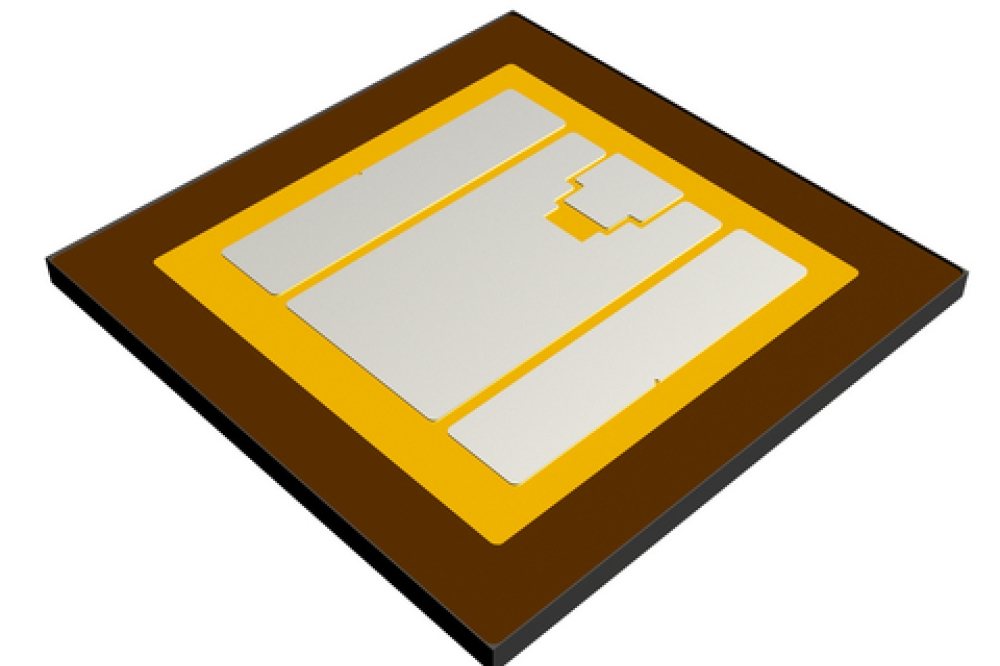

The devices are sandwiched between two heat sinks and then stacked together. Large-channel water coolers extract heat from the sides to form a stack module (see picture above).

Each diode laser is individually fast-axis collimated, and its design tailored so that the beam emitted from the stack is symmetric and matched to the application. For first-stage power scaling, two of these stack modules are geometrically combined. Further power scaling via polarisation beam combining remains possible. The process head also includes beam-shaping optics to deliver the beam to the work surface and an in-path camera for visual process control.

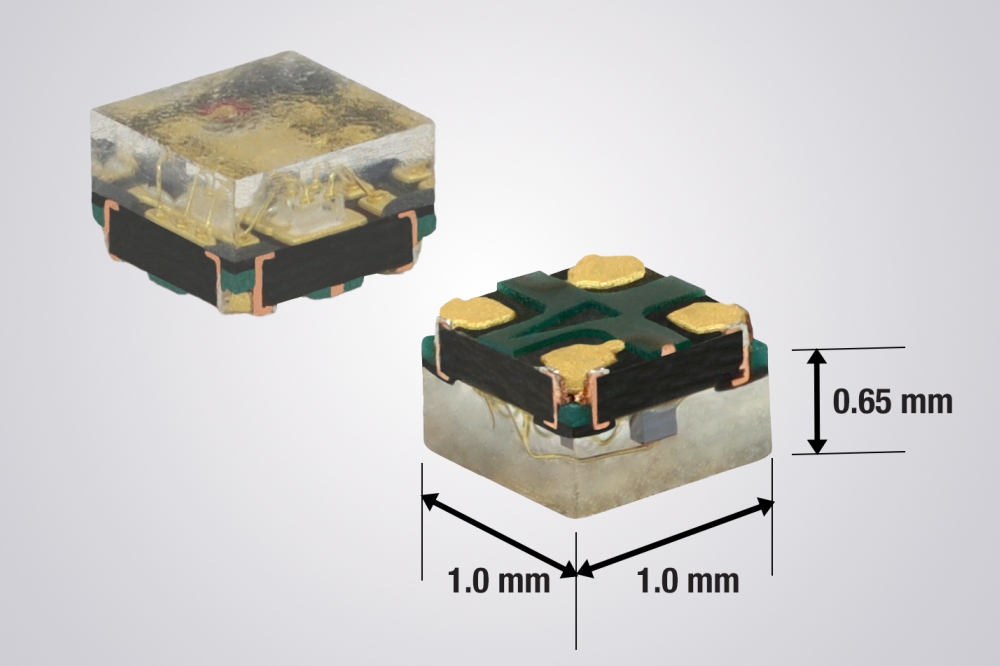

A first-generation process head has been transferred to the project partner Photon Laser Manufacturing (PLM). It is mounted on a robotic arm with a control software made by the project partner SKDK GmbH. The assembly delivers 1 kW CW in a 1 mm2 spot.

At the conference, FBH reported first results of AM trials using this new process head: a test structure was 3D-printed on a substrate with a wire-feeding speed of 7 mm/s. The resulting structure was 3 mm in height and was made of 10 layers of melted metal.

Parallel to process demonstrations, the team worked to scale module conversion efficiency and brightness by optimising the diode lasers themselves.

Devices with a narrower stripe width (1.2 mm → 0.8 mm), shorter resonator length (6 mm → 4 mm), and higher front-facet reflectivity (0.8 percent → 4 percent) were assessed – without changing the epitaxial layer structure.

In a laboratory demonstration using two stack modules, they team showed that these changes increased the conversion efficiency from 35 percent to 50 percent at 1 kW and halved the spot size from 1 mm2 to 0.5 mm2 . As a result, the power density in the focal area doubled, increasing from 1 kW/mm2 to 2 kW/mm2.

This work was supported through the "AMBER ProFIT Innovation" project SAMBA which is co-financed by the European Fund for Regional Development (ERDF) Berlin under contract number 10193579.

References

S. Arslan et al: Conf. on Lasers and Electro-Optics/Europe and European Quantum Electronics Conf. (CLEO/Europe-EQEC 2023), Munich, Germany

M. Hübner et al; Proc. of SPIE, vol. 13345, High-Power Diode Laser Technology XXIII, Photonics West, San Francisco, USA (2025).

M. Wilkens et al; Proc. CLEO/Europe-EQEC, Munich, Germany, Paper CB-8.5 (2025)