GaN HEMTs enter SiC territory

Rigorous testing demonstrates the reliability and robustness of commercial 1250 V GaN HEMTs paired with a low-voltage silicon MOSFET to ensure normally-off operation.

BY KAMAL VARADARAJAN, ALEXEI ANKOUDINOV, ROBERT YANG, ALEXEY KUDYMOV, BHAWANI SHANKAR, KARTHICK MURUKESAN AND SORIN GEORGESCU FROM POWER INTEGRATIONS

Material properties govern the performance of power devices. And due to the superior properties of GaN, power devices made from this semiconductor are ideally suited for high-efficiency power conversion. Thanks to this, GaN HEMTs are being adopted in increasing number in commercial power-supply designs covering a broad range of applications, where they take advantage of this wide bandgap technology’s fast switching capability with low losses.

Today’s designers have a broad choice, when it comes to the manufacturer of the GaN HEMT, but blocking voltages are limited. Many products on the market operate below 200 V, or in the

600 V - 650 V range. But beyond 650 V, only a few manufacturers have released devices with a rated voltage of 900 V or more. Part of the reason behind this limitation is that GaN HEMT technologies tend to employ silicon substrates, a foundation that hampers scaling to voltages beyond 900 V, due to the need for very thick buffer layers that add significant processing challenges.

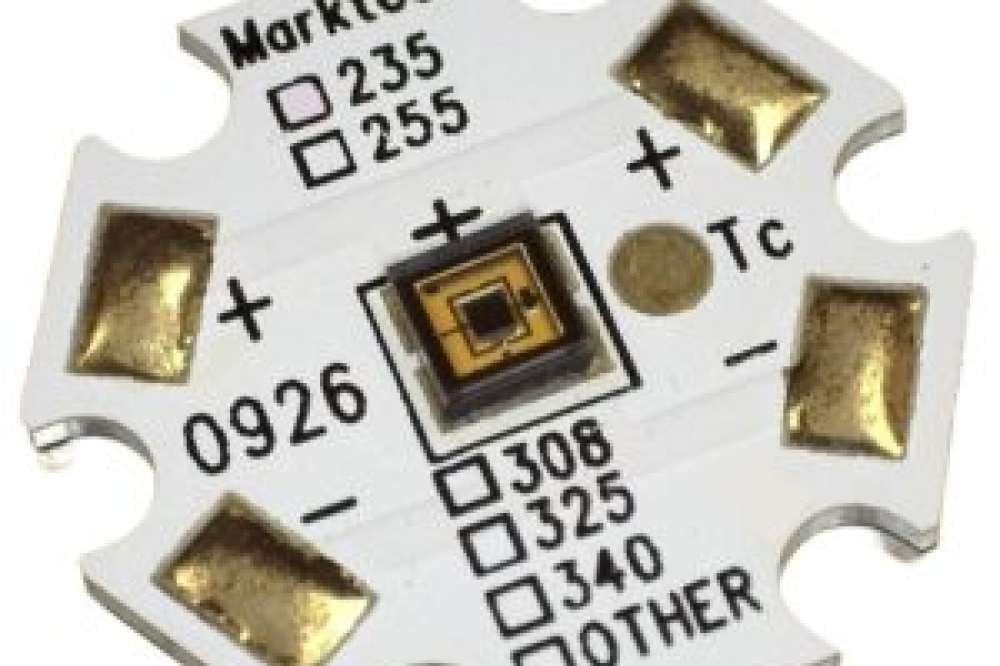

Figure 1. (a) Circuit schematic for the 1250 V GaN cascode switch. (b)

Flyback switcher IC with the 1250 V GaN cascode, primary, and secondary

controllers.

Due to this, designers needing wide-bandgap power devices with a rating of 1200 V or more have been constrained to using SiC switches. However, this is an expensive choice, with cost still providing a significant barrier to SiC adoption.

To address this shortcoming, our company, Power Integrations, is breaking new ground by offering high-voltage GaN devices. Our proprietary technology enables extension beyond 900 V purely by device design and with no modification to the underlying epitaxial layer structure. These readily available products are a compelling alternative to SiC at 1200 V and beyond.

If a high-voltage power-conversion switch is to enjoy market success, lower cost and excellent performance has to go alongside reliability. We have devoted much effort on this front, involving high-voltage reliability qualification tests of a 1250 V GaN cascode switch, with a focus on some of the most critical aspects associated with high-voltage evaluation. Read on to discover our findings.

Figure 2. (a) Output characteristics of a 330 mW, 1250 V GaN cascode

device illustrating high current capability. (b) Typical off-state

characteristics demonstrating leakage remaining stable beyond 2000 V.

Power supply designers can reliably specify an operating peak drain-to-source voltage of 1000 V when employing a 1250 V GaN cascode device, as this caters for the industry-standard 80 percent de-rating. For industrial applications, this extent of de-rating provides significant headroom, and is particularly beneficial in challenging power grid environments where robustness provides an essential defence against grid instability, surge, and other power perturbations. Another market for the 1250 V rated GaN switch results from the prevalence of 800 V bus architectures, with this device enabling cost-effective, significant performance improvements in various sub-systems in electric vehicles while providing the derating needed to ensure high system reliability.

A cascode configuration

Our 1250 V GaN HEMT is a normally-on, depletion-mode device. To realise effective normally-off operation, which is essential for safe operation of power electronic systems, it is connected in series with a low-voltage silicon MOSFET in a cascode configuration (see Figure 1 (a), which provides a circuit schematic for the cascode switch, comprising 1250 V GaN and a low-voltage silicon MOSFET). The 1250 V GaN cascode is incorporated as the primary side switch in a flyback switcher IC, which also includes primary and secondary side controllers (see Figure 1 (b)).

Measurements of pulsed output characteristics of a typical 330 mΩ, 1250 V GaN cascode device demonstrate its high-current capability and device scalability, assets that aid the addressing of high-power applications (see Figure 2 (a)). Our 1250 V cascode devices also exhibits excellent off-state characteristics, with measurements on a typical HEMT showing stable leakage to beyond 2000 V, ensuring excellent transient overvoltage capability (see Figure 2 (b)). This strength shows that our 1250 V devices offer a significant safety margin when compared with silicon and SiC devices with similar voltage ratings.

Ensuring field reliability

While good on-state and off-state characteristics are valued, they must go hand-in-hand with meeting and exceeding industry-standard reliability qualification requirements, in order to ensure reliable operation in the field. Here we share results meeting this goal, obtained from critical high-voltage reliability stress evaluations, covering both static and dynamic conditions. These tests were performed as part of our qualification of the 1250 V GaN HEMT for power-conversion applications.

One common test is the high-temperature reverse-bias (HTRB) test. This is an off-state reliability stress test that evaluates the long-term stability of the power device under a high drain-to-source bias, with a high temperature employed to accelerate thermally activated failure mechanisms under high electric-fields over an extended period.

We performed the HTRB stress test of our 1250 V GaN cascode device in a 150 °C ambient environment, using an off-state drain-source voltage of 1000 V (80 percent of 1250 V rating) for 1000 hours. Our device passed this test, fulfilling all specifications defined in JEP198 – it is the JEDEC guideline for reverse-bias reliability evaluation procedures for GaN power-conversion devices. One critical parameter to monitor during the HTRB stress test is the off-state drain-to-source leakage current. We observed excellent device leakage stability, validating the suitability of our cascode devices for high-reliability applications at high voltages (see Figure 3).

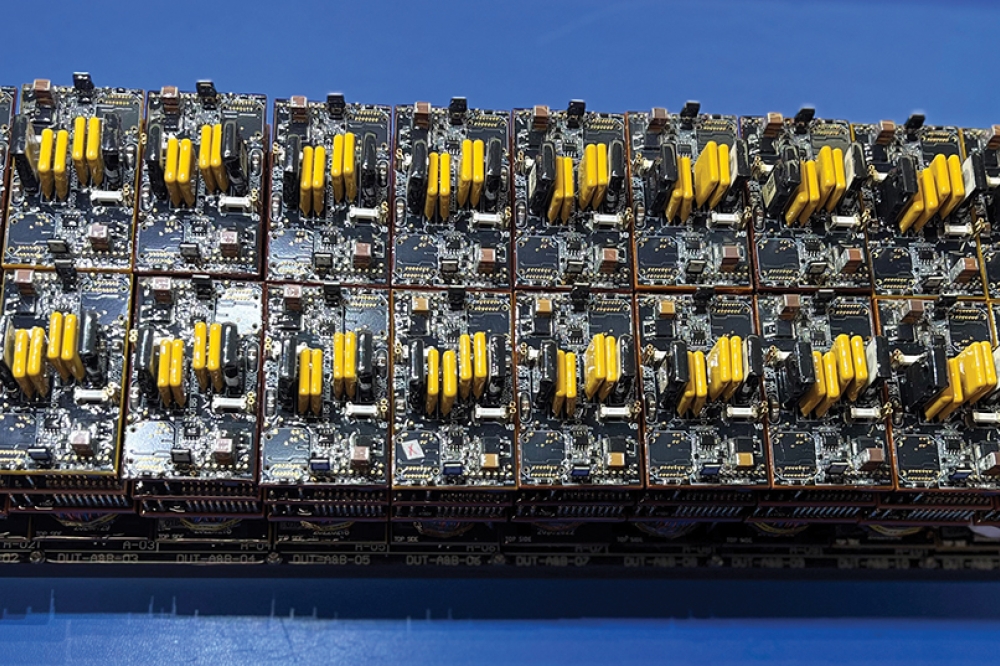

In addition to the HTRB qualification test, we determined intrinsic off-state failure rates, extracted by running tests on a large number of units under accelerated drain-source voltage conditions (2100 V to 2200 V) across multiple temperatures (80 °C to 120 °C). Test conditions are shown in Table 1.

Based on the time-to-failure Weibull distribution obtained from this set of experiments, we extracted: a voltage acceleration factor, using an exponential model; and a temperature acceleration factor, via an Arrhenius model. These factors enabled a projection of failure rate under typical use conditions. Our model predicts a cumulative failure rate of 1 part per million in more than 15,000 years of operation at 1000 V/100 °C (see Figure 4), indicating a significant built-in reliability margin for our 1250 V GaN cascode power device.

For many high-reliability deployments, such as industrial applications, reliability requirements go beyond just passing the HTRB-based off-state reliability qualification stress test. That’s because HEMTs are often exposed to harsh external environmental conditions, where they have to operate continually, or for extended periods of time, in extreme mission-critical applications. In these demanding conditions, it is crucial for HEMTs to pass the HV-H3TRB test, which involves a controlled high humidity environment, an additional stressor to the original HTRB test. This stress test, incorporating additional failure modes produced by moisture penetration, examines all aspects of the device, including its passivation layer, active and termination design, and underlying structures.

Figure. 3. Stable off-state drain leakage through 1000 hours of high-temperature reverse-bias stress at 1000 V/150 °C.

We undertook the HV-H3TRB stress test of our 1250 V GaN cascode device in an 85 °C ambient environment with a relative humidity of 85 percent, stressing with an off-state drain-source voltage of 1000 V for 1000 hours. These conditions follow JEDEC standard JESD22-A101.

Clean passing results were obtained for this stress test. We paid particular attention to the most critical parameter, the off-state drain-to-source leakage current, monitoring this at various times during the HV-H3TRB stress test. Our device exhibited excellent leakage stability, validating its suitability for high-reliability industrial applications (see Figure 5).

A key concern that initially delayed the commercial introduction of GaN HEMTs by many of its manufacturers is reliability when switching in high-voltage applications. Studies would show that the device’s on-resistance increased immediately after turn-on compared with the DC condition. This phenomenon, known as dynamic RDS(ON), is widely attributed to charge-trapping effects within the device under high electric-field strengths. A number of techniques have been employed to address this issue, including epitaxial structure engineering and carefully optimised processing techniques.

In response to the field reliability implication, JEDEC recently introduced a guideline JEP180, detailing dynamic high-temperature operating life (DHTOL) testing. This document specifies switching reliability evaluation procedures for GaN power-conversion devices.

Figure 4. Weibull distributions indicating time-to-failure under

multiple accelerated stress conditions and the projected distribution at

1000 V/100 °C.

Using the JEP180, we evaluated switching reliability of our 1250 V GaN cascode in a custom testbed with the capability to evaluate multiple units in parallel at 125 °C. For this test we employed the most stringent operating conditions – hard-switched turn-on and turn-off at 1000 V – based on the switching locus described in JEP180. The dynamic RDS(ON) during high-voltage switching is of particular interest. Improperly designed GaN HEMT devices tend to exhibit a significant increase in RDS(ON) during high-voltage switching transitions due to additional electron trapping, which can have a detrimental effect on the converter efficiency, or in extreme case, result in hard failure.

Table 1. Accelerated evaluation conditions in the off-state.

We have monitored variations in the RDS(ON) of our 1250 V GaN cascode over the course of 1000 hours of DHTOL stress at 1000 V, a peak current of 2 A, and a junction temperature of 125 °C. This test shows stable performance from the earliest timepoint, with a minimal shift of less than 20 percent (see Figure 6). It’s a degree of stability that’s on par with state-of-the-art 650 V GaN HEMTs tested under similar hard-switching conditions.

A key implication of this result, and the others described in this article, is that GaN HEMTs can be scaled to more than 1200 V without any compromise in performance, including critical hard-switching capability. Rigorous testing demonstrates their robustness to meet all potential high-reliability use cases.

A real-life application

To highlight the capability of our 1250 V GaN HEMT in real-life applications, we have deployed this device in a 60 W, 24 V/2.5 A flyback power supply, built using the switcher IC (see Figure 1 (b)). By evaluating the steady-state operation of the flyback power supply running at a peak drain-source voltage of 1000 V, we confirmed stable operation with corresponding switching waveforms (see Figure 7 (a)).

Measurements have determined low, stable operating temperatures for the power supply, realised without any external cooling over long periods of continuous operation, with a peak drain-source voltage of 1000 V. This is an encouraging result, validating the minimal magnitude and effect of the shift in RDS(ON) during DHTOL stress evaluation. The maximum temperature of the 1250 V GaN HEMT remained below 55 °C (see Figure 7 (b)), indicating a temperature rise of only 30 °C in this application compared to ambient.

Figure 5. Stable off-state drain leakage through 1000 hours of HV-H3TRB stress at 85 percent relative humidity/85 °C/1000 V.

While the GaN cascode is designed to operate with a peak drain-source voltage below 1000 V in a continuous mode, it can accommodate momentary increases in supply voltage up to a peak of 1250 V. This transient voltage capability allows the GaN cascode to continue to switch through the surge event for short periods without suffering a hard failure. We demonstrated this attribute by increasing the input voltage until the peak drain-source voltage during switching reached the maximum rated value of 1250 V without running into any abnormal operation (see Figure 8).

Figure 6.Stable RDS(ON) observed during 1000 hours DHTOL with minimal shift (less than 20 percent).

As well as being extremely robust, the flyback power supply designed with the 1250 V flyback switcher IC operates with a best-in-class full-load efficiency exceeding 92 percent at a 700 V input (see Figure 9).

High-voltage GaN HEMT roadmap

Our work demonstrates the capability of 1250 V GaN HEMTs as a credible alternative to SiC. We also offer flyback switcher IC products based on a 1700 V GaN HEMT, clearly establishing that our technology can be scaled to even higher voltages.

With our proprietary and improving GaN HEMT technology, particularly suited to ultra-high voltages, devices with ratings beyond 2000 V that are currently catered for by SiC are now within close reach. For power supply designers, the portfolio of reliable, alternative wide-bandgap power switch is expanding.

Figure 7. (a) Steady-state switching waveform illustrating 1000 V Peak VDSv. (b) Steady-state thermals indicating temperature rise below 30 °C during continuous switching and a VDS(PK) of 1000 V.

Though lateral GaN device structures have a fundamental limitation in matching the specific-on-resistance – that’s the on-resistance per unit area – of vertical devices, it is possible to significantly increase power levels through improvements in packaging and thermal management.

Figure 8. Switching waveform illustrating transient overvoltage capability up to a peak VDS of 1250 V.

When higher switching frequencies, improved efficiency, high reliability and lower costs compared with SiC are factored in, high-voltage GaN HEMTs are compelling candidates in industrial, data centre, automotive and other high-reliability applications over a wide power range.