A wider bandgap

A recent analyst report from France-based Yole Développement takes a look at the wide bandgap materials currently available for power electronics applications.

As expected SiC, and GaN feature heavily, but report author and compound semiconductor market and technology analyst, Hong Lin, also scrutinises larger bandgap materials that promise even higher power device performance.

"In the beginning, [industry players] said silicon carbide would never ever happen, and today we have commercial devices," she tells Compound Semiconductor.

"Materials such as gallium oxide and aluminium nitride are at very early stages of development but given time there could be new opportunities for new materials," she adds.

Thanks to its high bandgap and doping possibilities at room temperature, development of gallium oxide for power electronics applications is under way.

Japan-based public research and development body, New Energy and Industrial Technology Development Organisation, is driving progress, part-funding a next generation power electronics project called 'Research and development of Fundamental Technologies of Gallium Oxide Power Devices'.

Key partners include a cohort of Tokyo-based firms including power conversion business, Tamura, analog IC design and manufacturer, New Japan Radio, and optoelectronics developer, Koha, alongside the National Institute of Information and Communication Technology and the Tokyo University of Agriculture and Technology.

Crucially, as part of the project, researchers have developed and demonstrated the first ever Ga2O3 MOSFETs on single crystal Ga2O3 substrates, claiming excellent device characteristics.

High on-stage drain current, large off-state breakdown voltage, extremely low leakage current and high on/off drain current ratios have been demonstrated, opening the door to power devices with lower losses during switching operations. Indeed, researchers are confident performance will surpass that of Si, SiC and GaN-based devices.

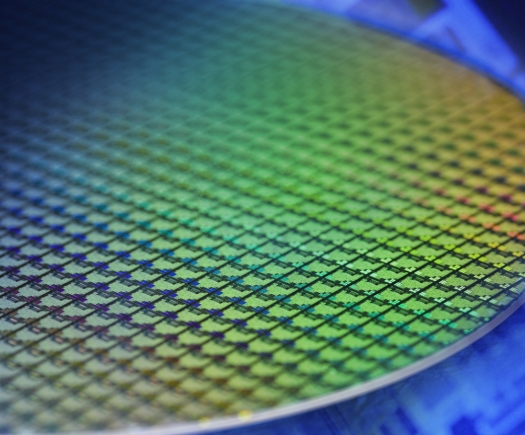

As Lin highlights, cheap, large single crystal Ga2O3 wafers can be mass manufactured via melt-growth in the same way as sapphire substrates are produced, also holding promise for low cost, high volume power device manufacture.

"In terms of materials development, this technology is quite impressive," she says. "Two inch commercial single crystal wafers are commercially available while six inch wafers have also been grown."

But while cheap, native single crystal substrates are a massive draw for future power device manufacture, Ga2O3 has a relatively low thermal conductivity, raising challenges for heat extraction in power devices.

"Device designers will be working on this and there are many ways to extract heat, such as thinning wafers to reduce the thermal resistance," she highlights. "This problem can be resolved but it still needs more research and development."

"We have proof-of-concept devices but development is at a very early stage; we need many years yet to get to a final product," she adds.

Power electronics progress

At the same time, suppliers of AlN-based UV LEDs are now diversifying activities and targeting power electronics markets, following weak demand. According to Lin, key players here include Crystal IS and HexaTech, both from the US, as well as Germany-based CrystAL-N.

"Aluminium nitride has been traditionally used in UVc LEDs but market growth has not been so fast, so companies have been thinking of ways to use [the technology] for power electronics," she says. "It has a very very high bandgap, so high performance devices [are possible]."

Indeed, just last year, researchers from HexaTech and North Carolina State University, US, alongside Japan-based colleagues at Tokuyama, Fuji Electric and the Tokyo University of Agriculture and Technology unveiled the first vertical Schottky barrier diodes, on AlN substrates.

Unlike gallium oxide, AlN has a high thermal conductivity, alleviating heat dissipation problems at high power densities, but device challenges still exist. In recent years, work has been ongoing at HexaTech to develop novel doping schemes for high voltage power devices. However, as Lin asserts: "Doping this material is going to be the main challenge."

What's more, AlN wafers aren't cheap. Production is still at low volumes and with no real applications yet driving demand, costs are likely to remain relatively high.

"Like gallium oxide, devices are only at a proof of concept stage right now and researchers are in the process of improving device performance," says the Yole analyst.

"We saw the first SiC diodes in the year 2000 and it has taken fifteen years to establish commercial devices," she says. "Researchers must be able to prove they can make good performance devices and then, if industry players find commercially-available devices don't quite work for an application, we will see many opportunities for these new materials."