Kyma and Quora announce GaN partnership

Kyma Technologies and Quora Technology have announced a strategic partnership in the development and commercialisation of GaN substrate materials.

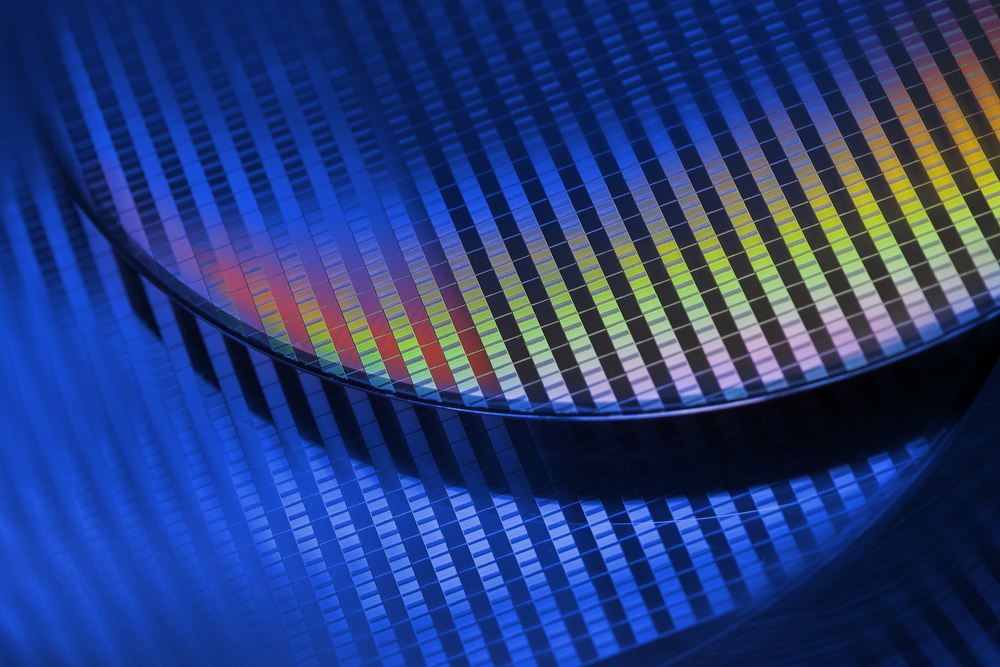

Kyma is a developer of wide bandgap semiconductor (WBGS) materials solutions, including GaN, AlN, Ga2O3, and diamond. Kyma's GaN materials products include free-standing GaN substrates and GaN templates.

Quora Technology is a new privately held fabless technology startup, located in Silicon Valley, California, focusing on energy efficient and high performance wide bandgap (WBG) semiconductor materials and device solutions.

Quora Technology is currently commercialising its QST substrate technology which is fully diameter scalable (6-inch, 8-inch, 12-inch and beyond) and engineered to alleviate stress from epi layers, allowing deposition of tens of microns of high quality and low dislocation density GaN on 6-inch or larger diameters.

According to Quora, the QST substrate technology is poised for rapid adoption in WBGS industry with the validated performance results in LED, power and RF applications by the major GaN device manufacturers.

Kyma and Quora have teamed to demonstrate that Kyma's high growth rate GaN processes can be used to realise a low defect GaN on QST template, which uses the QST properties and provides a very high quality epi-ready surface for GaN epitaxy growth and device fabrication.

Kyma confirmed that it could produce uncracked, low defect density (<108cm-2) 6-inch diameter GaN on QST templates that have up to 40 percent narrower X-ray diffraction (XRD) line widths, smoother surface morphology, and much lower bow than for similar structures grown on sapphire.

Low bow is important, as well as other wafer shape issues, for achieving high yielding and advanced device fabrication. Wafer shape control, including GaN cracking or entire wafer breakage, is a major problem with traditional approaches on large diameter wafers and as such is one of the major obstacles in front of WBGS industry which limits achievable economies of scale.

The companies have already succeeded in winning support on two separate US federal research projects, the first to develop manufacturing processes for making cost-effective large diameter high growth rate GaN on QST templates up to 8-inch diameter, and the second to take that approach to the next level to create 4-inch and 6-inch diameter free-standing GaN substrates.

In the first project, Kyma is developing an 8-inch diameter GaN growth tool that is designed to produce uniform low defect density GaN on QST wafers in GaN thicknesses up to 100 microns at a fast-cycle time which will support a low tool cost of ownership.

Kyma is already teamed with a leading OEM tool manufacturer to support rapid market penetration of the technology once the team further advances the growth process and proves its ability to support high performance device manufacturing. Kyma's device partners include leading US universities and multiple large device manufacturers.

In the second project, Kyma will create low defect density GaN boules and fabricate 4-inch and 6-inch substrates therefrom. The substrates will be made available to leading US device developers to prove out their ability to support high performance 1,200V vertical power electronic device operation.

Quora Technology president and CEO Cem Basceri commented: "We are very excited for Kyma to integrate its rapid GaN growth process on our high performance substrate technology, QST, for delivering low defect density and large diameter GaN wafers to the device manufacturers. This special class of material will hopefully improve the existing device processes, designs, and performances, and also unlock new applications."

Kyma president and CEO Keith Evans commented: "We are pleased to partner with the Quora Technology team. We believe they have a game changing baseline materials technology that will make a major impact on GaN based LED, high power switching, and RF device markets. By combining Kyma's advanced and high gowth rate GaN technology with Quora's QST technology, we have the potential to help device manufacturers to accelerate their roadmaps for making higher performance devices at lower cost."