Perovksite cells stay stable for 2 months

German team shows how solar cells can retain 99 percent of initial efficiency after 1450 hours of elevated temperature and illumination

In the current issue of the journal Nature Energy, researchers from the Helmholtz Institute Erlangen-Nuremberg of the Forschungszentrum Jülich in Germany have presented a perovskite variant that stands out for its special stability.

In tests at elevated temperature and illumination over 1450 hours of operation (2 months), the perovskite-based cell retained 99 percent of its initial efficiency.

"The Achilles' heel of perovskite solar cells is their low durability," explains Christoph Brabec of the Helmholtz Institute Erlangen-Nuremberg (HI ERN) at Forschungszentrum Jülich. "Classic silicon modules are quite durable. Even after more than 20 years in practical use, they lose little of their performance." Solar cells made of perovskite, on the other hand, usually lose efficiency after just a few days or weeks. Early cells could literally be watched ageing, with efficiency dropping within seconds or minutes of turning on the lights in the lab.

"The solar cell we have now presented in Nature Energy, on the other hand, impresses with its exceptional stability. The values are certainly among the best ever measured for a planar perovskite solar cell in a long-term test," Brabec said.

The illuminated cell had to survive 1450 hours at elevated temperatures around 65degC in the laboratory and remained largely stable throughout the test period. At the end, it still had 99 percent of its initial efficiency. "Long-term prediction is always difficult. But the perovskite solar cell we have now developed could certainly be operated for more than 20,000 hours under normal circumstances," estimates Brabec.

Success through high throughput

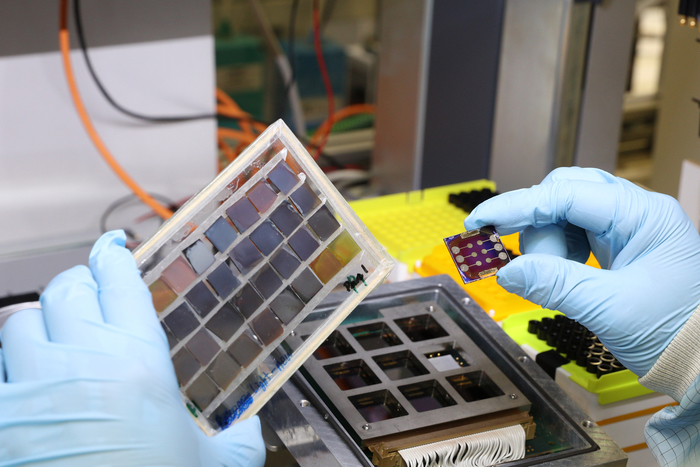

The result is no accident. In their search for the right material, the researchers systematically tested hundreds of different perovskite mixtures for their suitability using high-throughput methods. The researchers then used the best ones to build their cell.

"Even if you only rely on proven components, you come up with tremendous numbers of possible compositions that we can produce and test automatically using our methods. In other studies, there are sometimes even significantly more," explains Yicheng Zhao, who played a key role in the scientific investigations. "That is why we need to use a systematic approach to identify the best material combinations.“

Another important optimisation step concerns the stable contacts of the perovskite within the cell, which is built up in several thin layers. The ionic dopants or metal oxide nanoparticles commonly used to contact the cell tend to undergo secondary reactions at higher temperatures. This reactions can even lead to corrosion of the metal electrodes, as the researchers at HI ERN were able to demonstrate through measurements and scanning electron microscopy. Contact and electrical conductivity thus deteriorate at an early stage.

"To improve stability at the contact point, we packed the entire electrode in a kind of protective shell," Zhao said. A new double-layer polymer structure, with the bottom side un-doped and the top side doped with a non-ionic dopant, protects against degradation and ensures that the contact is maintained. On the one hand, this architecture protects the very sensitive interface to the perovskite, and on the other hand, it shows exceptionally stable conductivity, even at elevated temperatures.

For the future, the HI ERN researchers are now aiming for further efficiency improvements. "With an efficiency of 20.9 percent, the tested cell does not yet fully exploit the potential. 24 to 25 percent should be possible in the near future," explains Yicheng Zhao.

REF

'A bilayer conducting polymer structure for planar perovskite solar cells with over 1,400 hours operational stability at elevated temperatures' byYicheng Zhao et al; Nature Energy, December 16th 2021