Zuken and CSA Catapult present R&D results

R&D Collaboration provides electronics engineers with optimised tools to generate 3D models of power modules

Zuken, a design tools company, and the Compound Semiconductor Applications (CSA) Catapult are announcing an important milestone in their R&D collaboration aimed at building a development environment for compound semiconductor products.

CSA Catapult is a UK government funded non-profit organisation headquartered in South Wales that was founded to help the UK become a leader in compound semiconductors. Working with both large companies and start-ups CSA Catapult develops and commercialises new semiconductor technology applications.

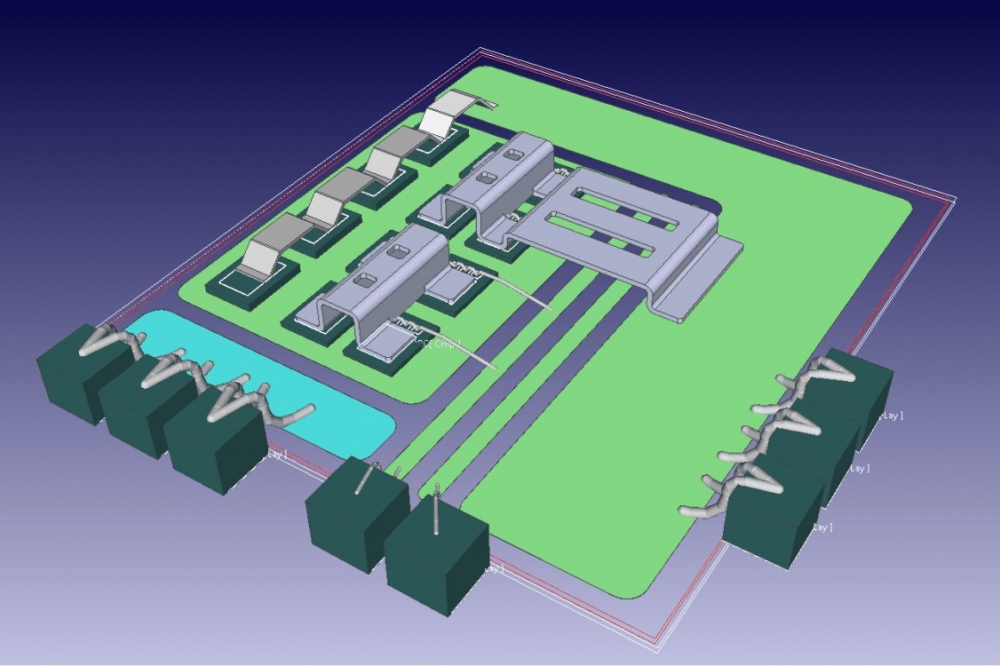

Collaborating with Zuken on a project to bring a power module layout from a graphical concept to a 3D model, CSA Catapult has identified several requirements and optimisations to Zuken’s CR-8000 Design Force chip, package and PCB co-design software. These will provide designers of power electronic products with the ability to co-develop mechanical and electrical design in unison.

The integration with industry simulation tools enables the efficient design iteration needed to effectively explore the design envelope for new compound semiconductor products.

As a result of the collaboration, an intuitive function was created that is used to generate interconnections between chips and copper layers in a substrate or a printed circuit board, as well as a function to export a CAD model in a format compatible with FEM software. These features will help designers to significantly decrease the time required to generate a 3D model of the power module substrate, chip layout, and chip-to-chip as well as chip-to-copper interconnections.

Alejandro Villarruel Parra, senior power electronics engineer at CSA Catapult, said: “The creation of a 3D model of the substrate, chip layout and chip interconnections is an important part of the early-stage power module design process. Zuken’s advanced design solutions have helped to provide a preview of the module performance, which in turn makes our decision-making process faster when several concepts are being compared or helps to steer the refinement of the module geometry if a concept has already been selected.”

Pictured above is a 3D power module design that uses the CR-8000 Design Force capability to capture Ribbon Bond wires and High Current Metal clips