EPC adds next gen 100V GaN FET

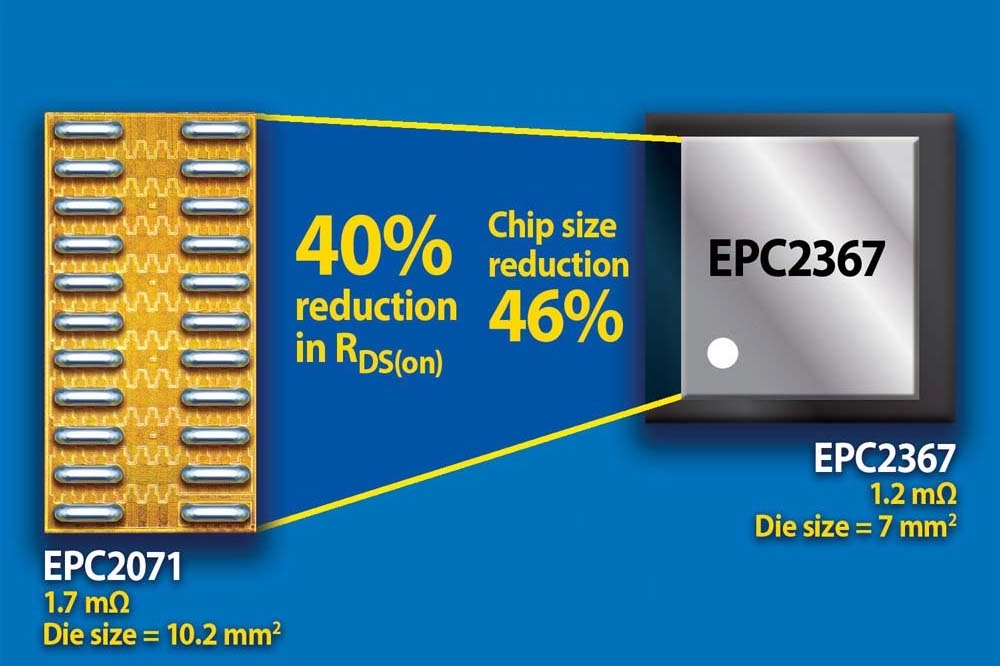

GaN specialist Efficient Power Conversion (EPC) has introduced the EPC2367, a next-generation 100 V eGaN FET for power conversion applications.

Designed for 48 V intermediate voltage bus architectures, the EPC2367 is claimed to significantly advance the performance of power systems by reducing power loss, increasing efficiency, and enabling more compact and cost-effective designs.

Key features include a low on-resistance (RDS(on)): 1.2 mΩ, which is a ~ 30 percent improvement over previous generation best-in-class devices. It also has a smaller footprint of 3.3 mm × 3.3 mm QFN package, reducing PCB space and enhancing thermal performance.

In addition the device is said to outperform competitors in hard and soft-switching applications, delivering superior efficiency and lower power losses.

It has four times the thermal cycling capability compared to previous GaN generations, ensuring robust long-term operation

The EPC2367 has been rigorously tested in hard and soft-switching applications. Performance results demonstrate higher efficiency across the full power range, with significant power loss reductions. In a 1 MHz, 1.25 kW system, EPC2367 reduces power losses while achieving 1.25× the output power compared to previous GaN and Si MOSFET alternatives.

The EPC90164 development board is a half bridge featuring the EPC2367 GaN FET. It is designed for 80 V maximum operating voltage and 35 A maximum output current.

The EPC2367 is priced at $2.81 each in 3 Ku volumes. The EPC90164 development board is priced at $200.00 each.