News Article

New partnership to enhance GaN power

Ammono, Kyma and MicroLink will work together on two galliium nitirde based power projects

Ammono is partnering with Kyma Technologies and MicroLink Devices in two novel projects related to power electronics as the supplier of GaN substrates.

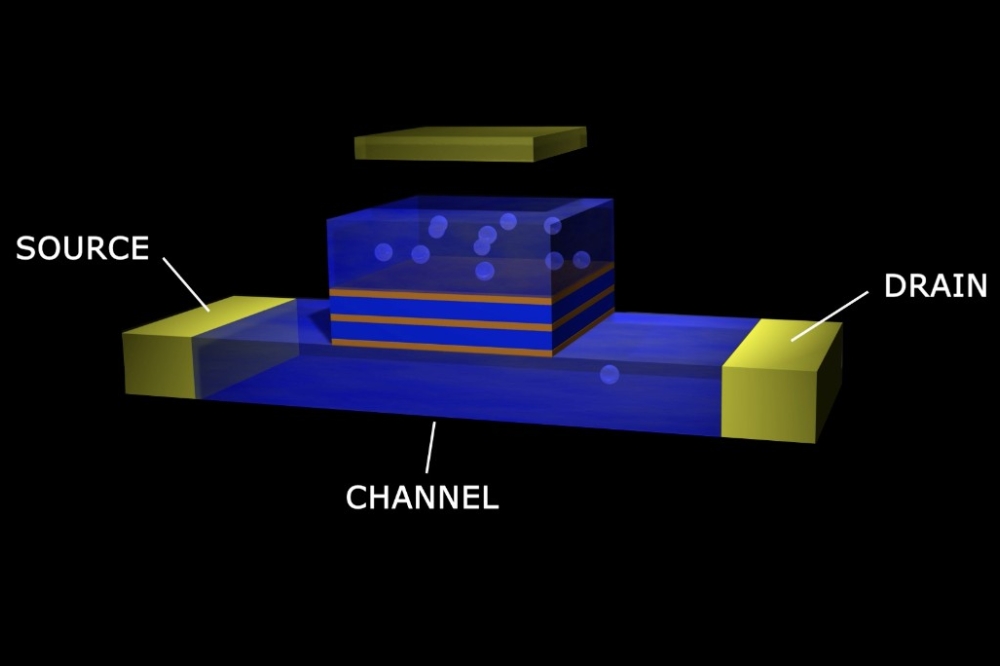

Based on a proprietary patented technology, Ammono has expertise in low dislocation GaN substrate manufacturing, exporting its products worldwide. Main applications of GaN are high power transistors, lasers and LEDs.

Those two partnerships are based on the development of new concepts, which explore the quality of our low dislocation GaN and allow new, better and more economic devices. The participation in ARPA-E projects shows the recognition of US industrial players for the breakthrough potential of our products,” says Piotr Wiliński, the Chief Commercial Officer at Ammono.

Both projects were funded by the Advanced Research Projects Agency-Energy’s (ARPA-E) SWITCHES program, short for “Strategies for Wide-Bandgap, Inexpensive Transistors for Controlling High-Efficiency Systems. The projects aim to find innovative ways to lower the cost and improve the efficiency of power electronics.

Ammono’s GaN wafers will enable Kyma to produce low-cost, high-performing boules needed for power semiconductor manufacturing.

Currently, growing boules from GaN seeds is slow, expensive, and inconsistent, which negatively affects manufacturing yield and electronic device performance.

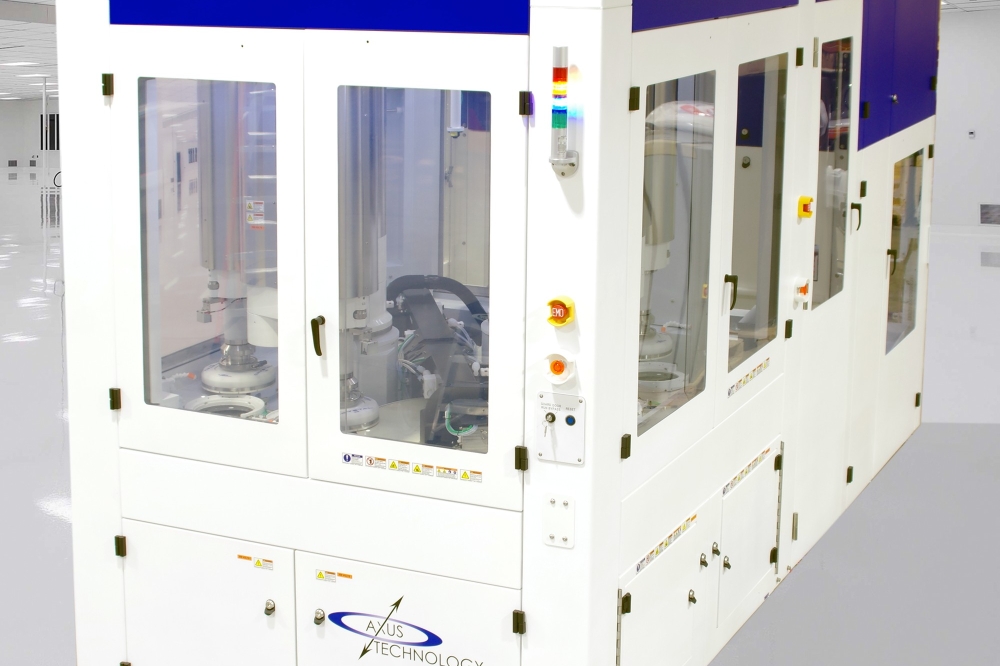

Kyma will select the highest quality GaN seeds and use their proprietary hydride vapor phase epitaxial (HVPE) growth process to rapidly grow the seeds into boules while maintaining high crystal structural quality and purity.

“We admire the great accomplishments of the Ammono team, and we are excited to win the support of ARPA-E to help Kyma and Ammono explore the natural synergies of our respective GaN crystal growth technologies,” states Keith Evans, Kyma’s President & Chief Executive Officer. Utilising Ammono’s GaN wafers, MicroLink Devices will develop an innovative method to remove the transistor structure from the wafer without damaging any components."

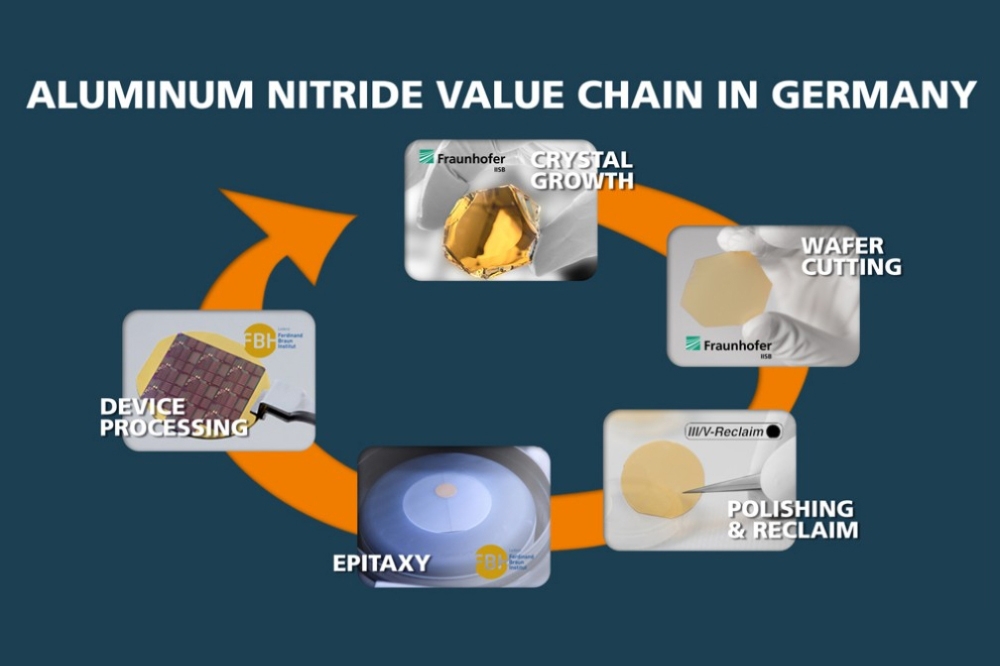

In conventional manufacturing processes, this expensive waf"er is permanently attached to the transistor, so the wafer can only be used once. MicroLink’s method will facilitate wafer reuse while significantly reducing costs to engineer affordable, high-performance transistors needed for power conversion.

He adds, “MicroLink Devices is an industry leader in developing manufacturable epitaxial lift-off technologies that reduce the cost and improve the performance of III-V semiconductor materials. Ammono's bulk GaN substrates are the ideal platform on which to grow high quality epitaxial GaN material. We look forward to working with Ammono to develop new technologies that will significantly reduce the cost of providing GaN epitaxial device structures with very low dislocation density.

Participation in these projects is a significant opportunity to affect the global energy conservation effort using Ammono’s proprietary, patented GaN wafers.

Based on a proprietary patented technology, Ammono has expertise in low dislocation GaN substrate manufacturing, exporting its products worldwide. Main applications of GaN are high power transistors, lasers and LEDs.

Those two partnerships are based on the development of new concepts, which explore the quality of our low dislocation GaN and allow new, better and more economic devices. The participation in ARPA-E projects shows the recognition of US industrial players for the breakthrough potential of our products,” says Piotr Wiliński, the Chief Commercial Officer at Ammono.

Both projects were funded by the Advanced Research Projects Agency-Energy’s (ARPA-E) SWITCHES program, short for “Strategies for Wide-Bandgap, Inexpensive Transistors for Controlling High-Efficiency Systems. The projects aim to find innovative ways to lower the cost and improve the efficiency of power electronics.

Ammono’s GaN wafers will enable Kyma to produce low-cost, high-performing boules needed for power semiconductor manufacturing.

Currently, growing boules from GaN seeds is slow, expensive, and inconsistent, which negatively affects manufacturing yield and electronic device performance.

Kyma will select the highest quality GaN seeds and use their proprietary hydride vapor phase epitaxial (HVPE) growth process to rapidly grow the seeds into boules while maintaining high crystal structural quality and purity.

“We admire the great accomplishments of the Ammono team, and we are excited to win the support of ARPA-E to help Kyma and Ammono explore the natural synergies of our respective GaN crystal growth technologies,” states Keith Evans, Kyma’s President & Chief Executive Officer. Utilising Ammono’s GaN wafers, MicroLink Devices will develop an innovative method to remove the transistor structure from the wafer without damaging any components."

In conventional manufacturing processes, this expensive waf"er is permanently attached to the transistor, so the wafer can only be used once. MicroLink’s method will facilitate wafer reuse while significantly reducing costs to engineer affordable, high-performance transistors needed for power conversion.

He adds, “MicroLink Devices is an industry leader in developing manufacturable epitaxial lift-off technologies that reduce the cost and improve the performance of III-V semiconductor materials. Ammono's bulk GaN substrates are the ideal platform on which to grow high quality epitaxial GaN material. We look forward to working with Ammono to develop new technologies that will significantly reduce the cost of providing GaN epitaxial device structures with very low dislocation density.

Participation in these projects is a significant opportunity to affect the global energy conservation effort using Ammono’s proprietary, patented GaN wafers.