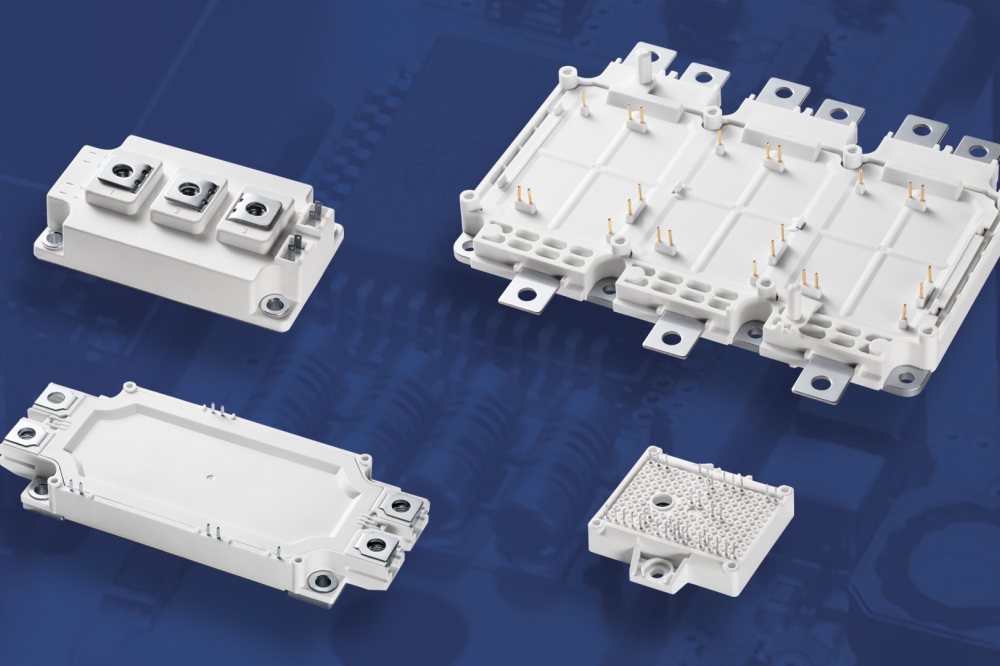

Russian venture targets SiC power

Russian microelectronics company PJSC Element and St. Petersburg Electrotechnical University LETI (ETU LETI) have formed a joint venture called Letiel LLC, according to a story on Interfax, a news agency covering Russia.

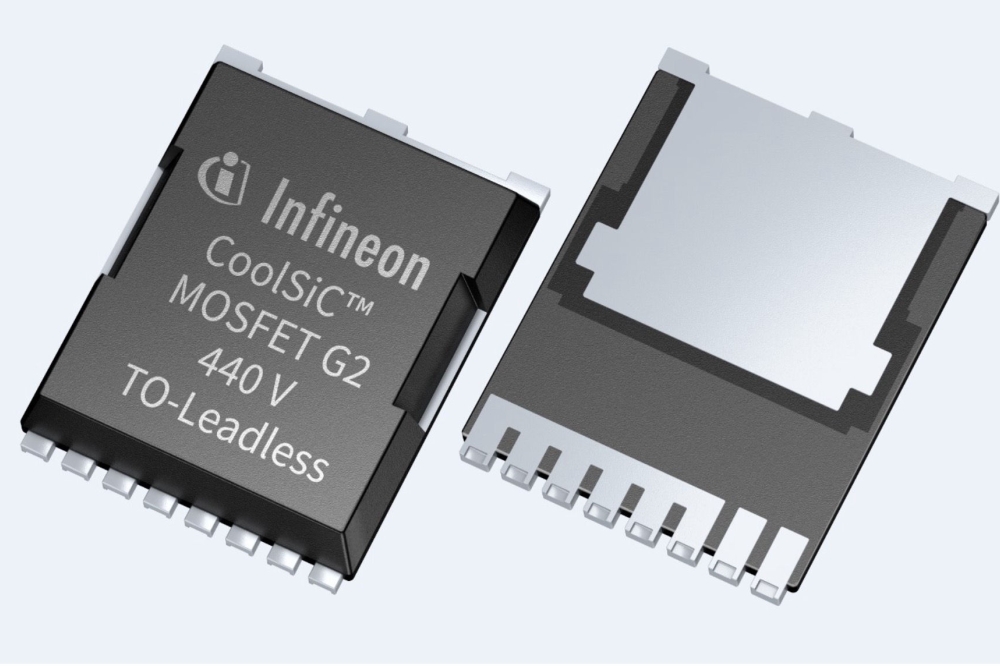

"We plan to actively develop the area of high-tech power semiconductor devices and in future take leading positions among global manufacturers of SiC devices," Element president Ilya Ivantsov told Interfax.

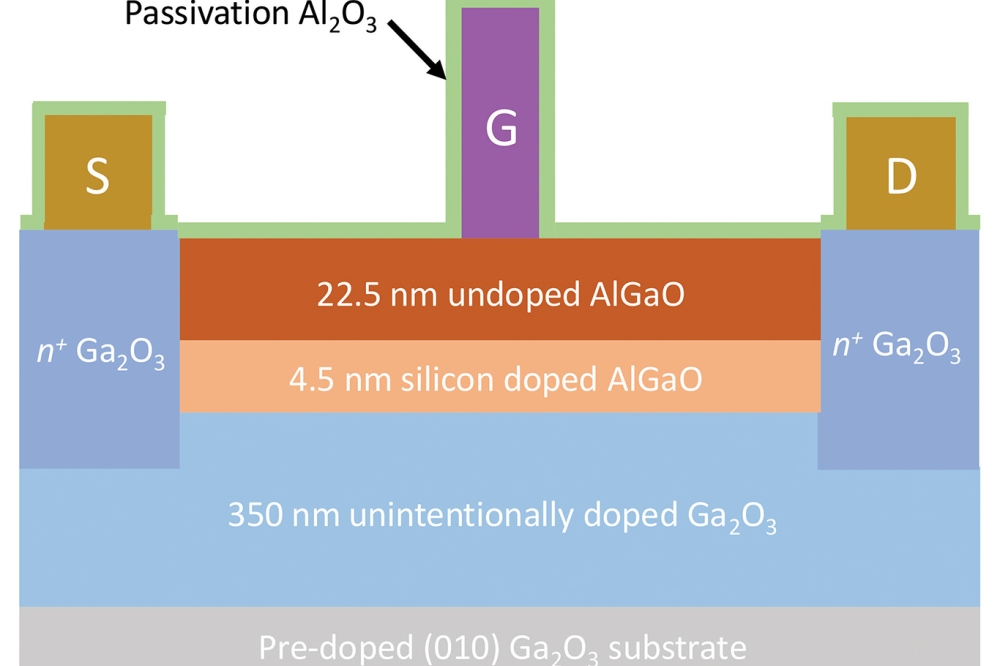

"The objective of the joint venture with LETI will be to develop and research technologies to produce SiC devices, on the basis of which we will be able to build a modern and competitive power electronics product and technology line for various sectors of industry," Ivantsov said.

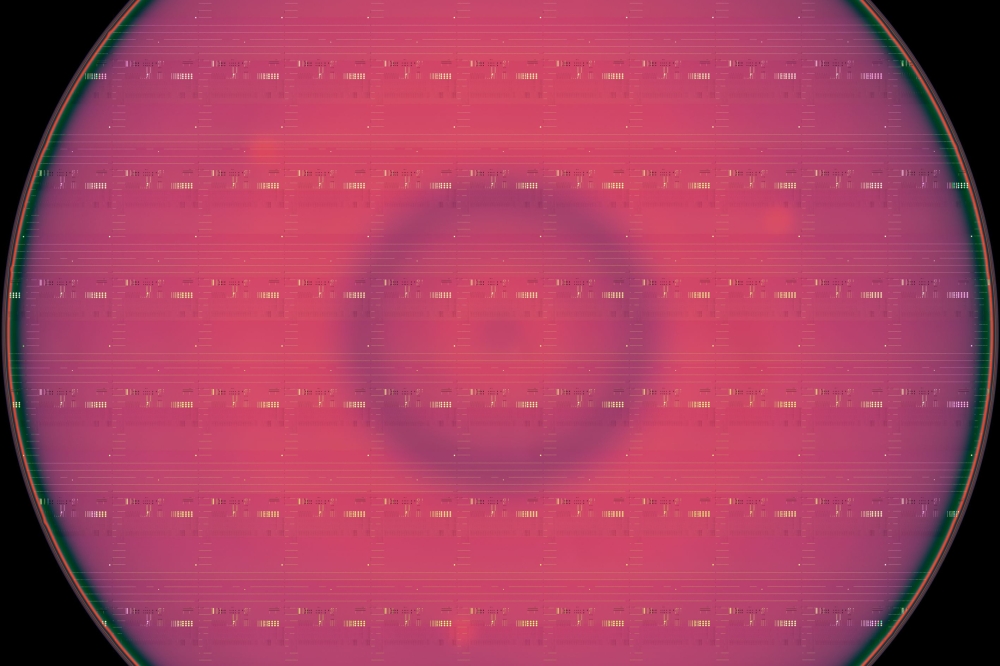

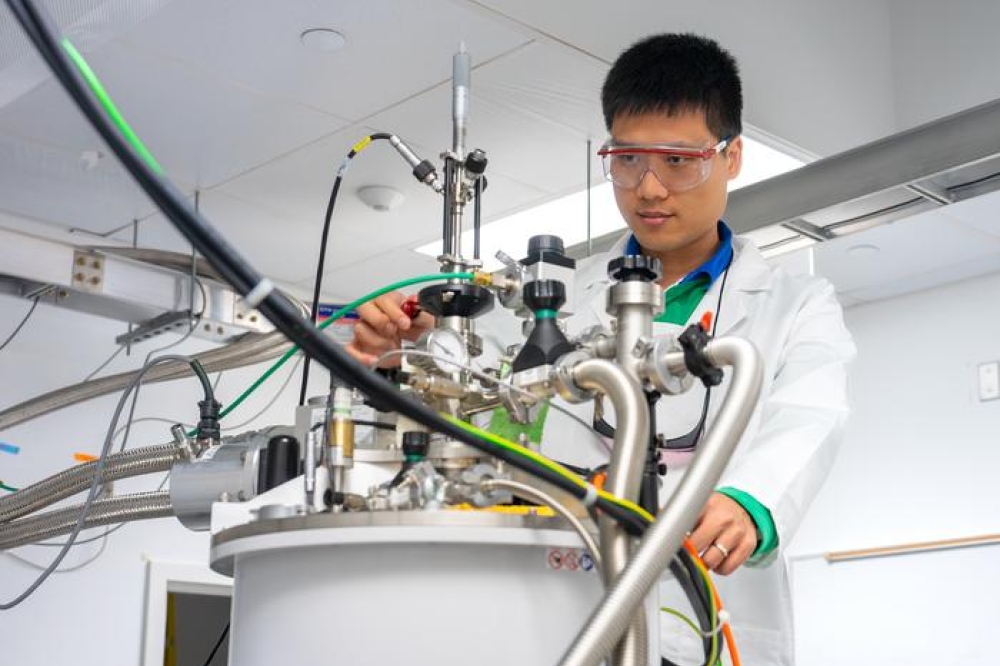

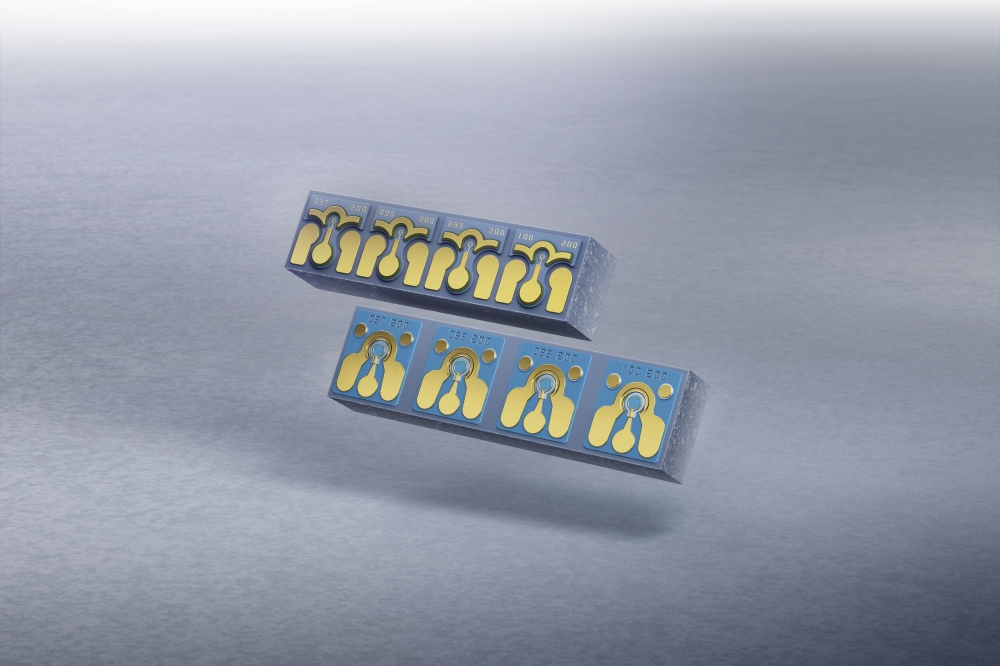

The new company will do research and development on SiC based power devices, which are used on production of modern electric vehicles, aircraft navigation systems and other sectors.

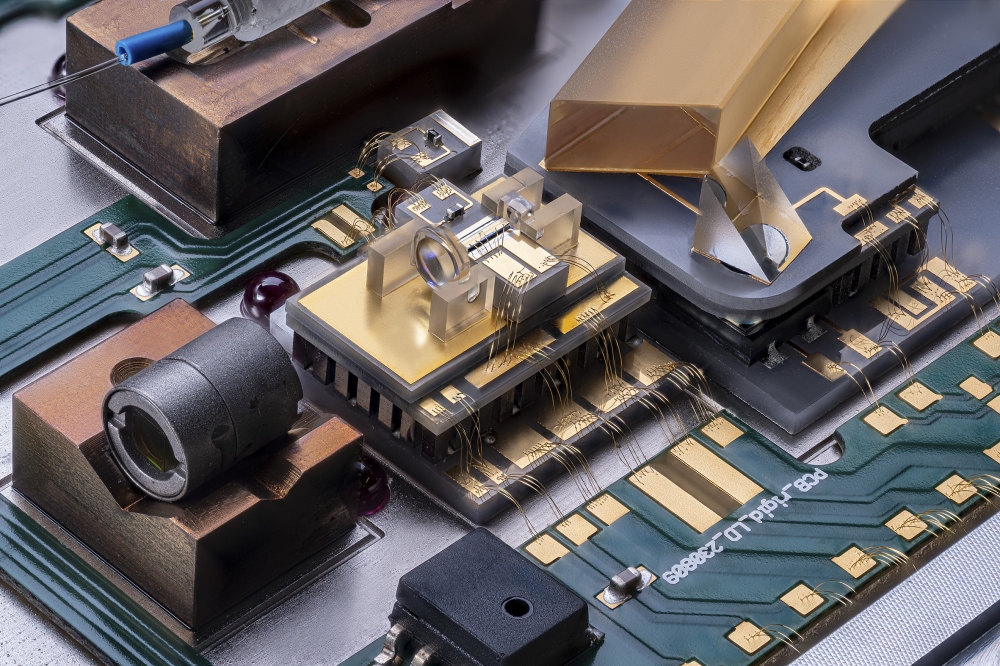

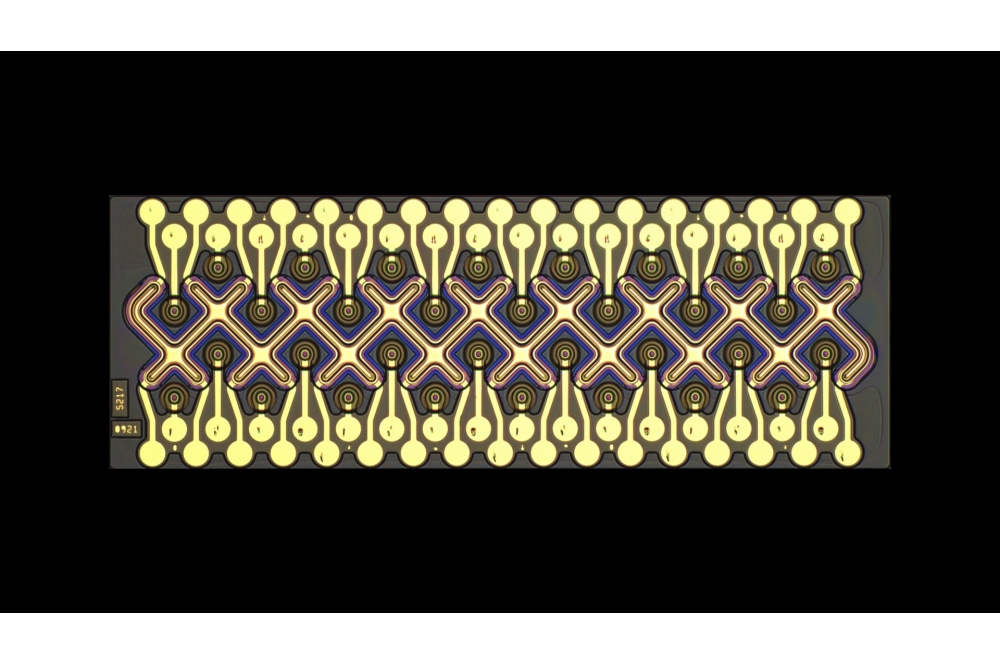

The venture, which is 51 percent owned by Element and 49 percent by LETI, also plans to study and design promising Photonic integrated circuits. These components are used in equipment for cellular networks, satellite systems and radiolocation.

"Mass production of solutions in the area of the electronic component base for power electronics and photon integrated circuits will be rolled out at the facilities of Element Group's new plant in Zelenograd," the company said.

The partners have not specified how much they are investing in the venture, which is headed by Element technology development director Konstantin Okunev.

Element was formed in 2019 with 19 microelectronics design, development and manufacturing assets belonging to investment group Sistema PJSFC and state corporation Rostec. Element's key portfolio companies are chip factory Mikron and microchip, molecular electronics research institute NIIME and electronics research institute NIIET. The group now includes about 30 enterprises.