News Article

High voltage GaN HEMTs on large diameter silicon substrates

Enkris demonstrates high voltage GaS HEMT structures on 200mm silicon with Aixtron MOCVD tool

Enkris Semiconductor has reported producing high voltage GaN HEMT materials on 200mm silicon with excellent uniformity and low buffer leakage combined with thickness uniformity of below 0.5 percent without edge exclusion. Under special conditions the uniformity value can be improved even further, says the company.

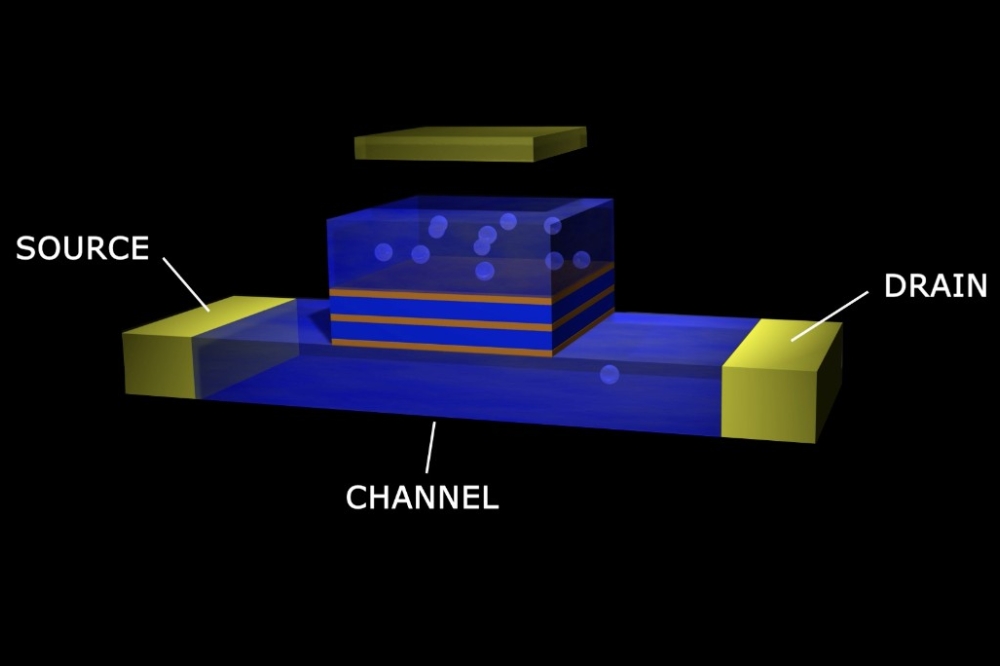

GaN-on-Si power devices have attracted much attention because of their potential applications in power electronics but due to the defective nature of heteroepitaxial GaN layers grown on silicon, GaN-on-Si power devices have suffered from high buffer leakage. Using GaN on large size silicon substrates is viewed as a cost-effective way to achieve high-volume production of GaN power devices but a large wafer bow combined with a high buffer leakage has hindered the further development of the GaN-on-Si technology so far.

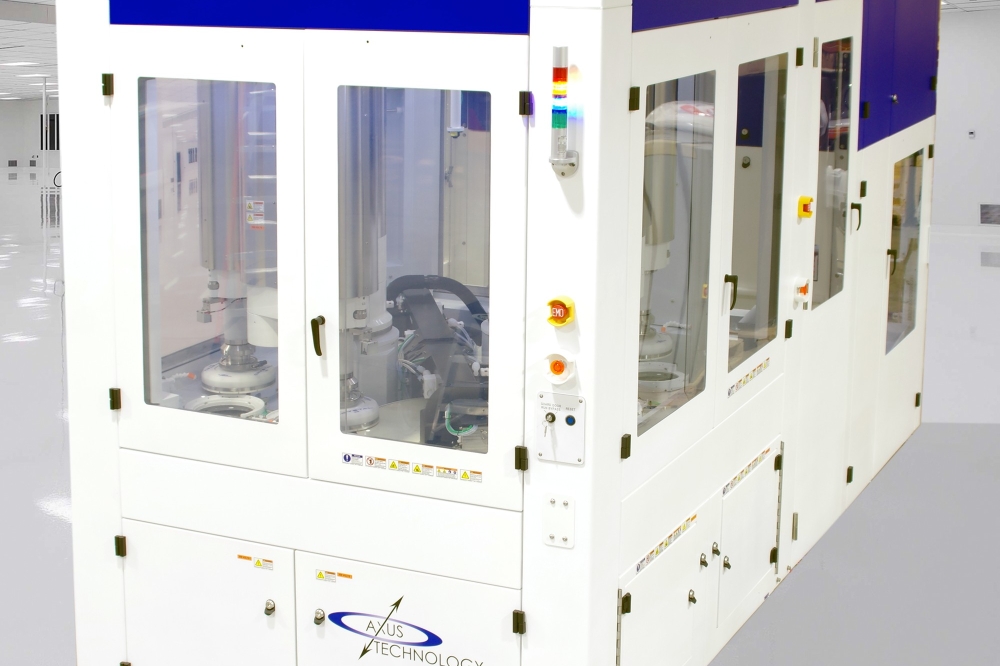

"Our process on 200mm silicon substrates shows that high breakdown voltage (less than 1600V) GaN power devices with low leakage currently can be achieved with relatively thin buffer layers of 4µm. They simplify the growth process, minimize the wafer bow and reduce the epi-cost significantly. Based on our processes which were applied on an Aixtron system, GaN-on-Si power devices may reach even higher voltages in the near future," commented Cheng Kai, co-founder of Enkris.

Frank Wischmeyer, Aixtron's vice president of power electronics says: "Enkris' remarkable success in achieving excellent layer quality and material properties show the capability of our technology for high-voltage GaN HEMT applications. Our MOCVD technology is enabling the integration of wide-bandgap semiconductors on large diameter silicon substrates."

GaN-on-Si power devices have attracted much attention because of their potential applications in power electronics but due to the defective nature of heteroepitaxial GaN layers grown on silicon, GaN-on-Si power devices have suffered from high buffer leakage. Using GaN on large size silicon substrates is viewed as a cost-effective way to achieve high-volume production of GaN power devices but a large wafer bow combined with a high buffer leakage has hindered the further development of the GaN-on-Si technology so far.

"Our process on 200mm silicon substrates shows that high breakdown voltage (less than 1600V) GaN power devices with low leakage currently can be achieved with relatively thin buffer layers of 4µm. They simplify the growth process, minimize the wafer bow and reduce the epi-cost significantly. Based on our processes which were applied on an Aixtron system, GaN-on-Si power devices may reach even higher voltages in the near future," commented Cheng Kai, co-founder of Enkris.

Frank Wischmeyer, Aixtron's vice president of power electronics says: "Enkris' remarkable success in achieving excellent layer quality and material properties show the capability of our technology for high-voltage GaN HEMT applications. Our MOCVD technology is enabling the integration of wide-bandgap semiconductors on large diameter silicon substrates."