Tanaka samples new deep UV-LED lid

SKe-Lid controls cracks and metallisation separation in applications such as semiconductor lasers and automotive sensor devices

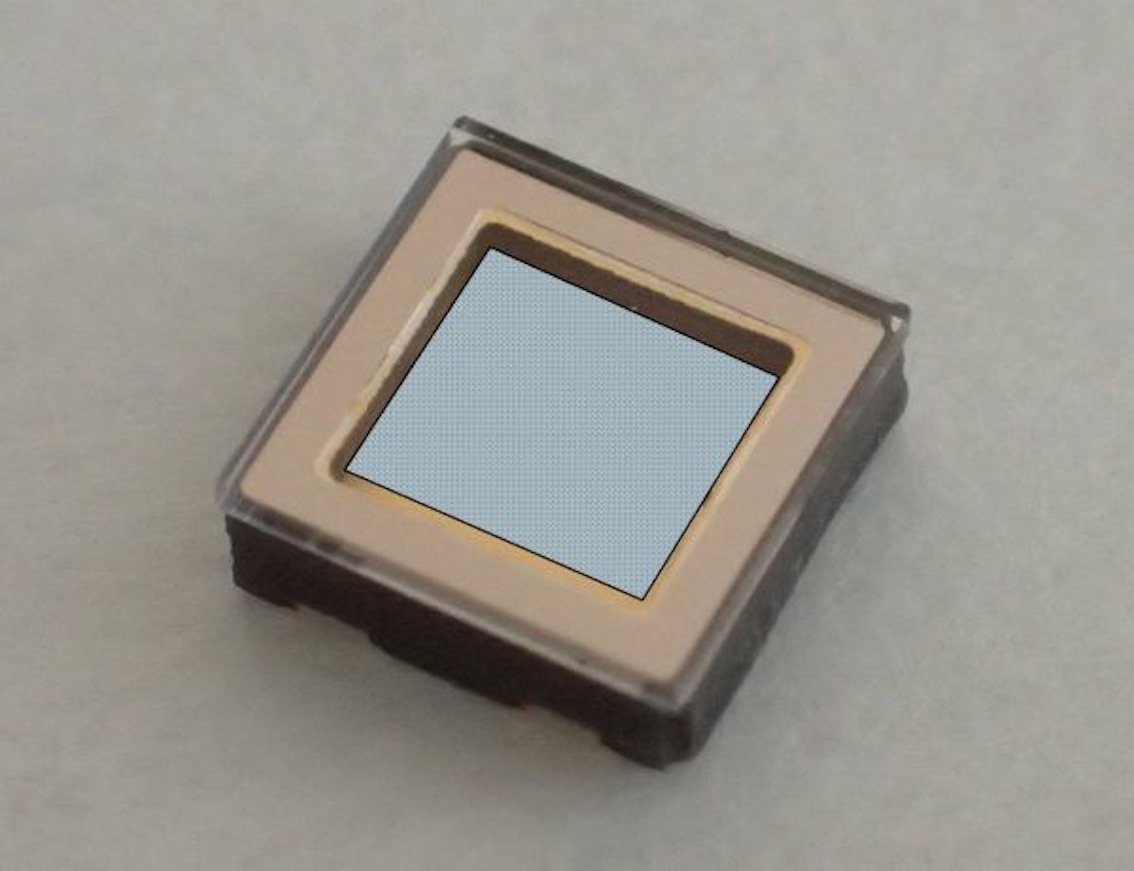

Japanese firm Tanaka Holdings has began sample shipments of SKe-Lid, a newly-developed glass lid made of quartz with gold-tin (AuSn) for use with deep UV LEDs.

Ske-Lid was developed with cooperation from Kyocera Corporation, Yamamura Photonics and Asahi Glass, which provided the glass material and ceramic package material, and Cross Osaka, which performed the seal testing.

Deep UV LEDs are expected to replace mercury lamps and have various applications including water disinfection in industry and air disinfection systems in healthcare. When used in combination with quartz glass, which has high transmissivity of deep UV wavelengths, and AuSn sealant, which has excellent airtightness and durability, however, there can be problems with cracking of the quartz glass and metallisation separation.

These new glass lids, made of quartz glass with AuSn solder, employ proprietary Tanaka Kikinzoku Kogyo technologies that properly control the shape and dimensions when applying the AuSn sealant to the quartz glass, making it possible to control cracking and metallisation separation. Higher yields are expected to contribute to improved productivity and lower costs.

According to the company, using SKe-Lid, the AuSn solder is already applied to the glass, facilitating the positioning with the ceramic package during sealing. AuSn airtight sealing also raises reliability and durability, and the use of proprietary technology controls the formation of cracks during application of AuSn to quartz glass with high transmissivity of deep UV wavelengths and ceramic package sealing.

Tanaka believes that Ske-Lid will contribute to higher productivity and lower costs of final products in the deep UV LED market, which will require higher outputs and reliability in the future.

As the shift to SMD proceeds and advances are made in autonomous vehicles, AuSn sealing will likely be used in semiconductor lasers too, which require high reliability and durability, and devices that require transparent covering materials such as automotive sensors.

Background to development

As a result of the Minamata Convention on Mercury coming into effect in August 2017, development of deep UV LEDs is proceeding as a replacement for mercury lamps used for water and air disinfection.

When deep UV LEDs are manufactured using conventional resin sealants, the UV rays cause degradation of the resin sealants, resulting in deterioration of device properties and lifespan. Also, when AuSn solder, which is highly resistant to UV rays, is used as the sealant material, cracks occur in the quartz glass and metallisation separation occurs due to thermal expansion between the package ceramics, window quartz glass, and AuSn sealant, giving rise to low yields.

Tanaka will display Ske-Lid at the Optics & Photonics International Exhibition 2018 (OPIE '18) at the Pacifico Yokohama from April 25 to 27.