Flosfia makes gallium oxide breakthrough

For power semiconductors, silicon dominates as a material, generating sales of more than $20 billion per annum. However, silicon power devices are far from perfect, wasting 10 percent of electrical energy as heat. Industry has been challened to achieve higher efficiencies with new semiconductor materials. Gallium Oxide (Ga2O3) is a very promising alternative. It comes in five different phases with the α-phase (which takes the corundum crystal structure) possessing the most attractive material properties.

Back in 2008, Kyoto University demonstrated the world-first single crystal growth of corundum α-Ga2O3 on sapphire. In 2015, Flosfia, a spin-off from Kyoto University, fabricated α-Ga2O3 schotty barrier diode (SBD) showing specific on- resistance of 0.1mΩcm2, the world's lowest specific on-resistance ever.

Flosfia then launched an engineering sample of α-Ga2O3 SBD packaged in TO220, a big step toward commercialisation.

Another challenge Flosfia has been taking on is to demonstrate a corundum α-Ga2O3 MOSFET. In 2016, Flosfia and Kyoto University jointly discovered p- type Iridium oxide (Ir2O3), which has the same corundum structure as the α-Ga2O3, could be expected to form a gallium oxide-based power MOSFET.

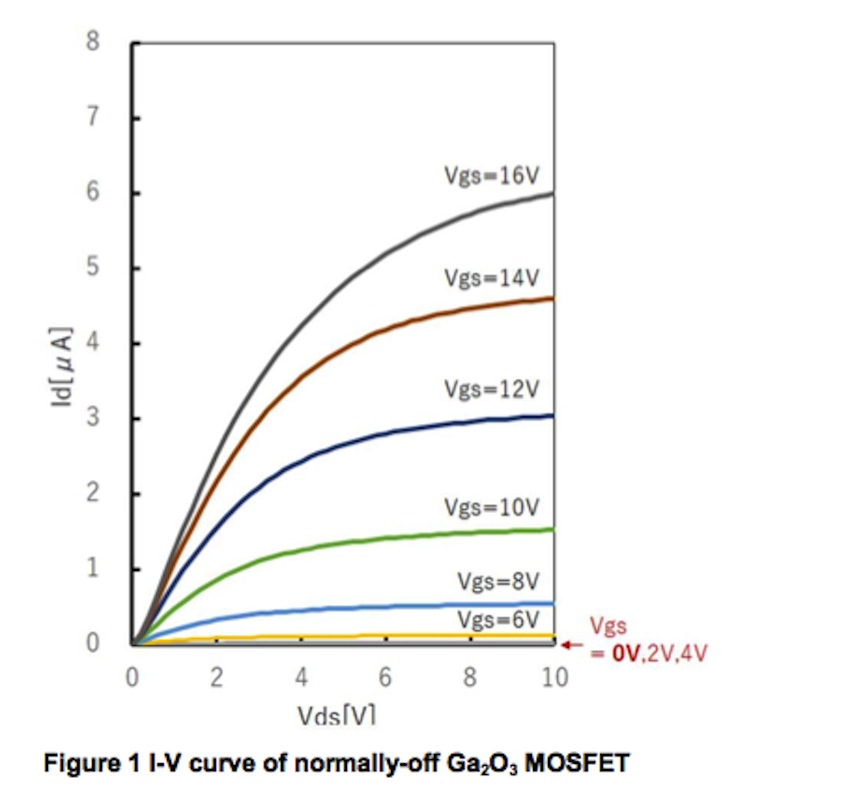

The latest result of this work is the world's first α-Ga2O3 normally off MOSFET. (Figure 1). The device comprises N+ source/drain layer, p-type well layer, gate insulator, and electrodes. (Figure 2 and 3) The gate threshold voltage extrapolated from I-V curve was 7.9V. The device is made of a novel p-type corundum semiconductor which functions as an inversion layer. This is a ground-breaking work since there has been no theoretical study predicting p-type material which is compatible with n-type Ga2O3 until the team discovered p-type Ir2O3 in 2016. So it has been considered very difficult to realise normally-off MOSFET.

Flosfia plans to manufacture corundum α-Ga2O3 power devices, GaO series, starting from SBD in TO220 and then MOSFET, which will be integrated in AC adopters, driver circuit of robots, electric vehicles, home appliances, power conditioner for solar cells, and so on. The GaO has a potential to miniaturise inverters down to tenths of and driving cost down to half of conventional ones while maximising conversion efficiency.