Substrate defects key to growth of 2D materials

Penn State researchers show that if TMDs are grown on hexagonal BN, 85 percent or more will point in the same direction

2D materials with unusual properties have created a great deal of interest in the 15 years since Konstantin Novoselov and Andre Geim pulled a single atomic layer of carbon atoms off of bulk graphene using simple adhesive tape.

2D semiconductors known as transition metal dichalcogenides (TMDs) are at the forefront with their promising properties for use in optoelectronics such as LEDs, photodetectors, or single-photon emitters.

"Our ultimate goal is to make monolayer films of WSe2 or MoS2 sheets, and to deposit them using CVD in such a way that we get a perfect single crystal layer over an entire wafer," said Joan Redwing, professor of materials science and electronics, and director of Penn State's 2D Crystal Consortium, a National Science Foundation Materials Innovation Platform.

The problem comes from the way atoms organise themselves when they are deposited on a standard substrate, such as sapphire. Because of the crystal structure of TMDs, they form triangles as they begin to spread across the substrate. The triangles can be oriented in opposite directions, with equal probability. When they bump and merge into one another to form a continuous sheet, the boundary they form is like a large defect that drastically reduces the electronic and optical properties of the crystal.

"When the charge carriers, such as electrons or holes, encounter this defect, called an inversion domain boundary, they can scatter," Redwing said. "This has been a classic problem with TMD growth."

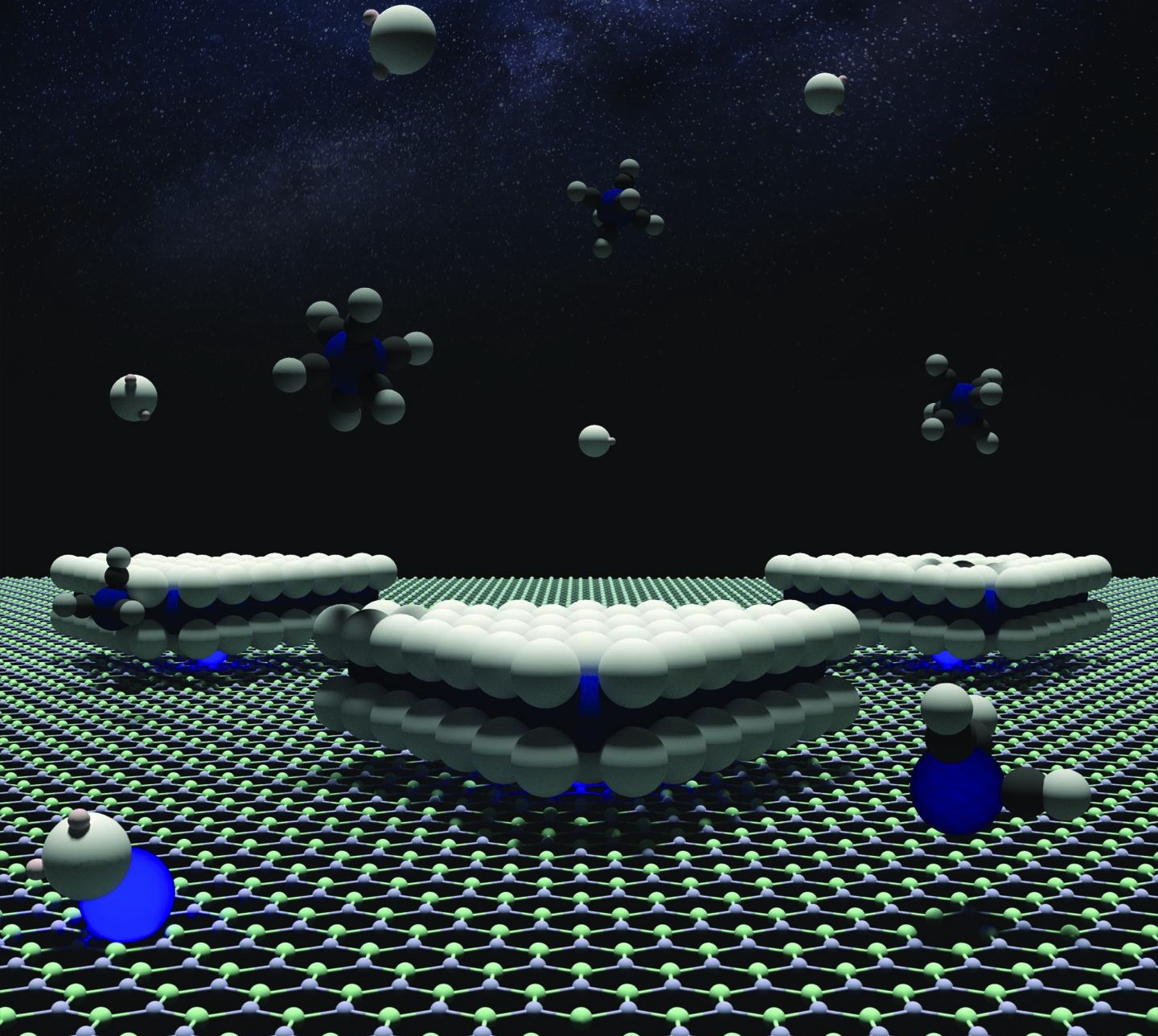

In recent publications in the journals ACS Nano and Physical Review B, researchers in Penn State's Departments of Materials Science and Engineering, Physics, Chemistry, and Engineering Science and Mechanics show that if the TMDs are grown on a surface of hexagonal boron nitride, 85 percent or more will point in the same direction.

Vin Crespi, distinguished professor of physics, materials science and engineering and Chemistry, and his group ran simulations to explain why this happened. They found that vacancies in the hexagonal boron nitride surface, where a boron or nitrogen atom was missing, could trap a metal atom - tungsten or molybdenum - and serve to orient the triangles in a preferred direction.

The improved material showed increased photoluminescence emission and an order of magnitude higher electron mobility compared to 2D TMDs grown on sapphire.

"Our next step is to develop a process to grow hexagonal boron nitride across a wafer scale," Redwing said. "That's what we're working on now. It's difficult to control defects and to grow a single crystal layer across a large surface. Many groups are working on this."

(The picture at the top shows a boron nitride surface with tungsten atoms anchoring triangular domains illustrating defect control of the orientation)