Rice team creates new tunable 2D material

New TMDC compound with sharp zigzag boundary shows promise for optoelectronics, advanced computing

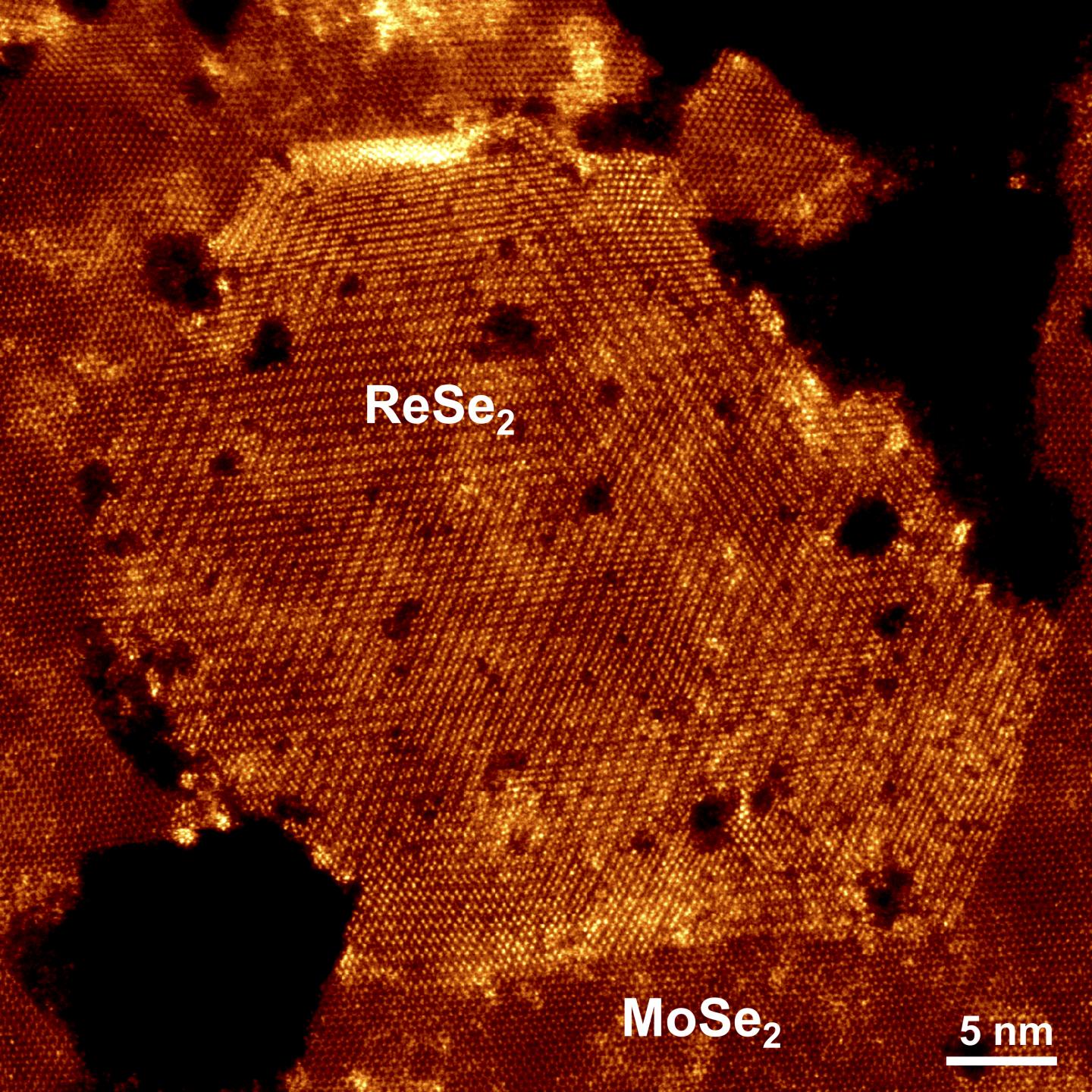

Researchers at Rice University, Houston, have created 2D flakes with two distinct personalities: MoSe2 on one side of a sharp divide with ReSe2 (rhenium diselenide) on the other. The sharp zigzag boundary between the elements in the material is unique, and is reported in the American Chemical Society journal Nano Letters.

The material is a 2D transition metal dichalcogenide (TMDC) heterostructure, materials that have been proposed as potential candidates for a variety of applications like quantum computing, neuromorphic computing, solar cells, and flexible field effective transistors. But at present, these materials face difficulties being implemented in these applications because of lack of large and sharp heterostructure interfaces.

Lead author Amey Apte, a Rice graduate student, explains. that atomically flat molybdenum-tungsten dichalcogenide heterostructures are more alloy-like, with diffuse boundaries between their crystal domains. However, the new material - technically, 2H MoSe2-1T' ReSe2 - has atomically sharp interfaces that gives it a smaller electronic band gap than other dichalcogenides.

"Instead of having one unique band gap based on the composition of an alloy, we can tune the band gap in this material in a very controllable way," Apte said. "The strong dissimilarity between two adjacent atomically thin domains opens up new avenues." He said the range of voltages likely spans from 1.5 to 2.5 electron volts.

Growing the materials reliably using a CVD technique involved the creation of a phase diagram that laid out how each parameter - the balance of chemical gas precursor, the temperature and the time - affects the process. Rice graduate student and co-author Sandhya Susarla said the diagram serves as a road map for manufacturers.

"The biggest issue in these 2D materials has been that they're not very reproducible," she said. "They're very sensitive to a lot of parameters, because the process is kinetically controlled.

"But our process is scalable because it's thermodynamically controlled," Susarla said. "Manufacturers don't have a lot of parameters to look at. They just have to look at the phase diagram, control the composition and they will get the product every time."

The researchers think they can gain further control of the material's form by tailoring the substrate for epitaxial growth. Having the atoms fall into place in accordance with the surface's own atomic arrangement would allow for far more customisation.

'Two-Dimensional Lateral Epitaxy of 2H (MoSe2)–1T′ (ReSe2) Phases' by Amey Apte et al; Nano Lett. July 29, 2019