Hygienic beer caps thanks to Fraunhofer UV-C-LED tech

Fraunhofer and Purion are working on replacing conventional UV lamps with UV-C LEDs for water purification

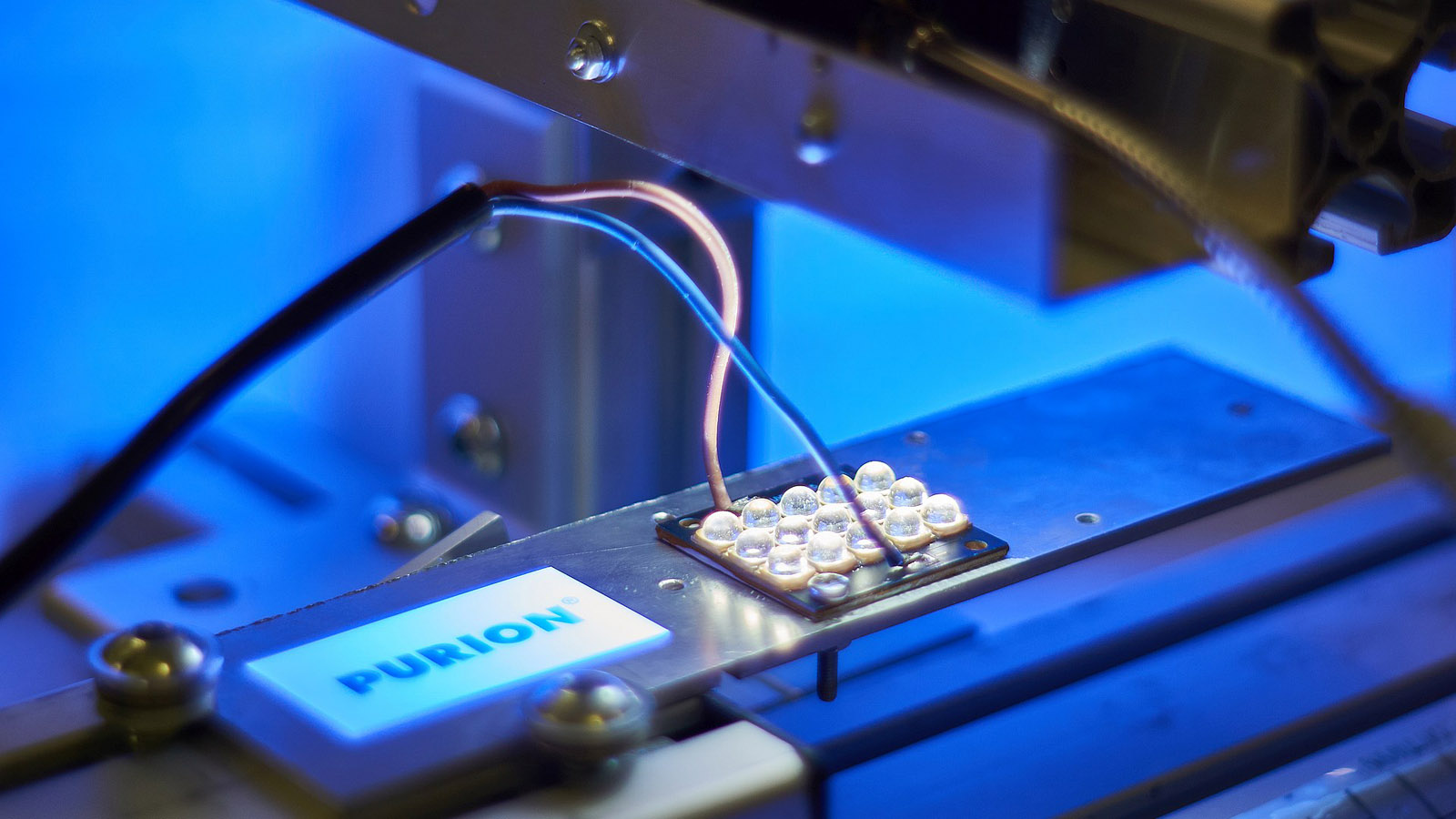

Researchers at the Advanced System Technology (AST) branch of the Fraunhofer Institute for Optronics, System Technologies and Image Exploitation IOSB in Germany, in collaboration with Purion GmbH, have been working on replacing conventional UV lamps with UV-C LEDs.

Based in the German town of Zella-Mehlis, Purion manufactures UV disinfection systems for purifying water. The technology is used in water coolers, for example, but also to keep drinks containers such as barrels, bottles and cans free of germs.

“Conventional mercury-vapour lamps emit light at 254 nm. As this lies below the optimal wavelength of 265 nm, the disinfection performance is not optimal,” says Thomas Westerhoff, scientist at Fraunhofer IOSB-AST. Further disadvantages of these lamps are their long warm-up phases, their short service lives and the fact that they cannot be deployed flexibly due to their bulky design. “For these reasons, we prefer UV LEDs, which emit at a maximum wavelength of 265 nm. Of particular interest are UV-C LEDs, because their radiation destroys the DNA of the pathogens much more effectively. The UV rays generate resonances in the nucleic acids of the DNA and break the bonds of the molecules open. This changes the cell nuclei of the micro-organisms in a way that renders cell division impossible. Consequently, the pathogens can no longer multiply.”

Flexible design of highly stable, mercury-free UV radiation sources

Following numerous practical tests, the researchers say they are now able to operate UV LEDs directly in water without the need for a tube to encase them. Thus they eliminate reflections to further increase the performance yield of the radiation sources. For the industrial partner Purion, the experts at Fraunhofer IOSB-AST have developed a special module that can disinfect the insides of beer caps during the production process before the bottles are filled with beer. This ensures that no germs get into the bottles during the production process. “We’re able to irradiate the inner surface of the caps with a UV power of four watts. Doing that with mercury-vapour lamps on such a small surface is almost impossible,” says the engineer.

The new technology is said to be highly versatile, and thanks to their small size and high radiation intensity the UV-C LEDs can also be used in medical devices, in order to sterilise liquids, surfaces and difficult-to-reach areas in a targeted manner. Endoscopes and ultrasonic probes, for example, can be efficiently disinfected using specially configured LED arrangements despite the complex irradiation geometries.

The technology project was supported by the German Federal Ministry of Education and Research (BMBF) as part of its 2020 Initiative “Advanced UV for Life.”