EpiWorld chooses new Aixtron Tool for SiC production

Chinese firm installs AIX G5 WW C MOCVD tool for next generation SiC epitaxial wafers

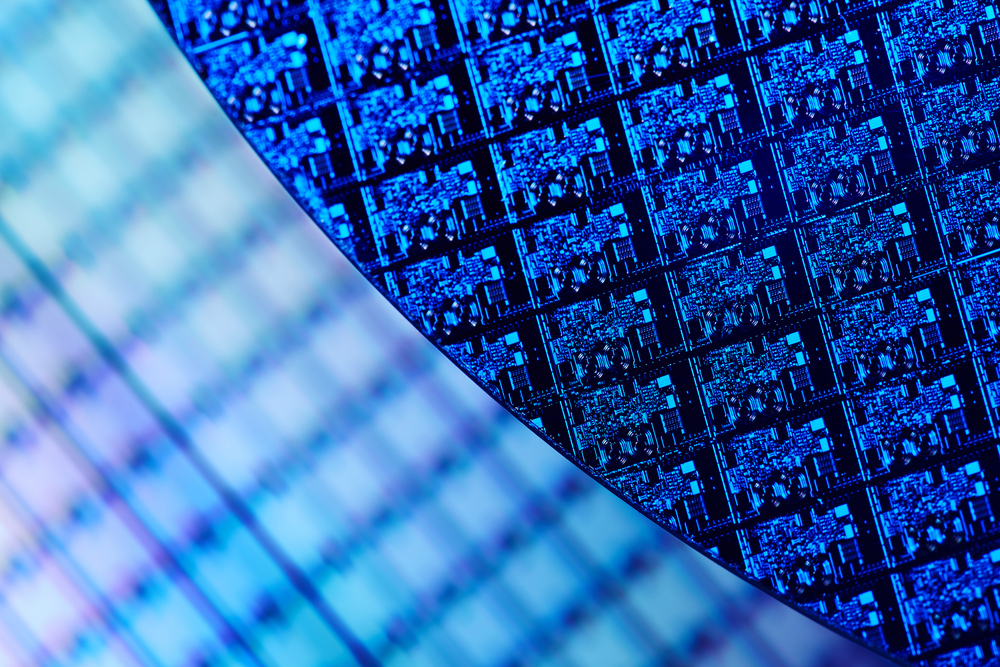

Deposition equipment firm Aixtron has announced that it has provided an AIX G5 WW C system to EpiWorld International for the further development of next generation SiC epitaxial wafers mainly used for the manufacturing of power devices for automotive applications.

The shipment and installation of Aixtron’s high-volume manufacturing system to EpiWorld’s cleanroom facilities in Xiamen, China, has been conducted in Q3/2019.

The AIX G5 WW C MOCVD tool is based on Aixtron’s fully-automated Planetary Reactor platform which is designed for high batch capacity and high throughput. The system offers flexible 6-inch or 4-inch configurations with the design aiming at squeezing production costs to a minimum, while maintaining excellent production quality, according to Aixtron.

EpiWorld seeks to further expand its production capacity to meet the increasing demand by customers. The company has already completed production lines for 4- and 6-inch SiC epitaxial wafers for making 600V, 1,200V and 1,700V power devices.

“In recent years, we have been qualified as a leading supplier of SiC epitaxy wafers by device manufacturers in the automotive and various other sectors. Therefore, we have a strong footprint in one of the most challenging industries. We had so far served over 100 customers around the world. With this new addition, our annual capacity will be increased to 60,000 wafers in 2019, " says Gan Feng, general manager of EpiWorld.

"Our recently completed phase I expansion of an 18,000 square meters new facility is designed to provide manufacturing space for an annual capacity of up to 400,000 wafers. As we and our customers have high quality standards, we rely on industry leaders such as Aixtron and their proven system technology to meet these requirements appropriately. We are looking forward to launch the high-volume production of our SiC epitaxial wafers with the AIX G5 WW C”, he added

Felix Grawert, president of Aixtron SE, comments: “We are delighted to cooperate with one of the leading epitaxy foundries to accelerate the further commercialisation of SiC. SiC will support the development of numerous high-end power electronics applications, meaning that we are paving the way for megatrends such as e-mobility or renewable energy.”