Enhancing AlN-on-sapphire templates with thermal cycling

Repeated thermal cycling slashes the threading dislocation density in sputtered AlN films grown on sapphire

Researchers at Mie University, Japan, have improved the quality of AlN-on-sapphire templates by thermal cycle annealing.

Their process, which drives down the dislocation density in AlN films, should help to increase the prospects for the deep-UV LED. Fabricating this device on a low-cost, high-quality substrate promises to increase its output power and drive its deployment in various applications, including medical treatment, water purification, and solar-blind communication.

Interest in AlN-on-sapphire templates has been fuelled by a lack of progress in bulk AlN, which is pricey and limited in availability and size. Turning to AlN-on-sapphire templates addresses all these issues, but the deposited layer can be riddled with defects, resulting from the large lattice mismatch with the substrate. Thicker layers can trim the threading dislocation density, but at the expense of wafer bow that leads to processing issues.

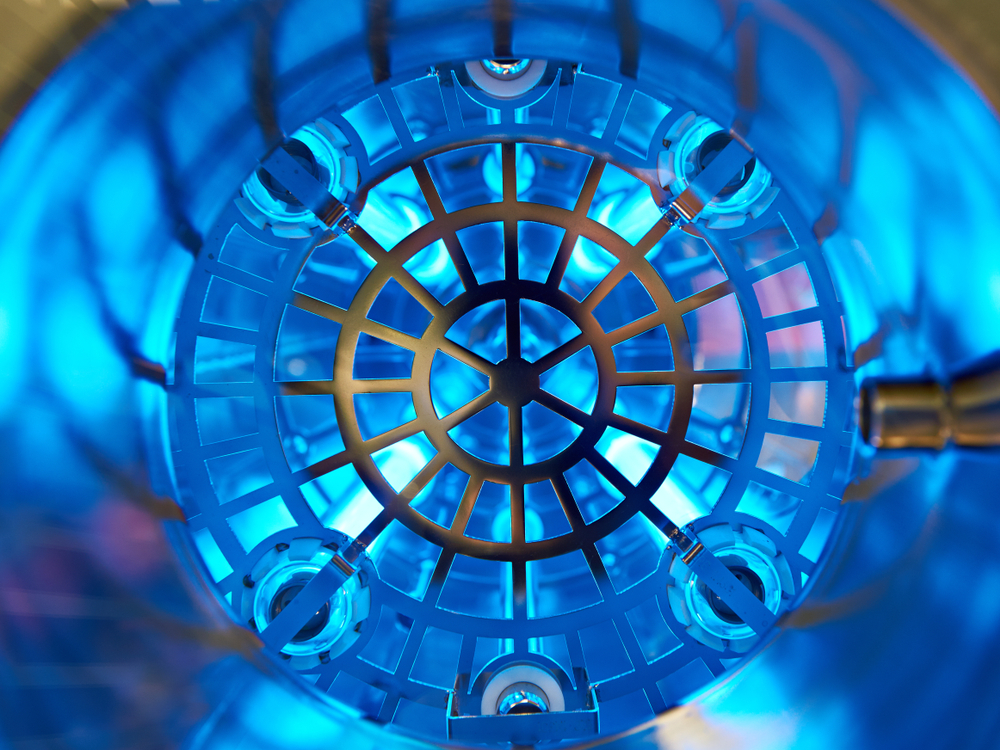

Back in 2016, the team from Mie University reported that they could reduce the threading dislocation density by one-to-two orders of magnitude with a process that included producing a pair of AlN-on-sapphire substrates by sputtering, and then placing the growth surfaces face-to-face and annealing under nitrogen gas.

Building on this work, the team have managed to further reduce the dislocation density by double sputtering and annealing. This quashes the threading dislocation density to below 108 cm-2, but the process is not trivial, requiring two sputtering and annealing steps, with success hinging on keeping the surface clean prior to the second sputtering.

To simplify the process, the team recently investigated thermal cycle annealing. It is a technique with a long history, having been employed in the 1990s to reduce threading dislocation density in GaAs, PbSe and germanium films grown on silicon.

Researchers, led by Hideto Miyake, have evaluated the impact of different thermal annealing cycles on a range of AlN films with thicknesses varying from 100 nm to 1000 nm. Values for the threading dislocation density have been estimated from X-ray rocking curves, by considering the peak’s full width at half maximum.

A range of thermal cycling conditions included variations in the number of ramps, the magnitude of the temperature difference, and whether with a two-step anneal it is better to use a higher temperature at the beginning or the end.

The team also investigated the impact of extending the time for annealing, considering a 370 nm-thick AlN film at a constant temperature. As time increased from 1 hour to 12 hours, the threading dislocation density fell from nearly 5 x 108 cm-2 to less than half this value. However, the longer times introduced other issues: macroscopic defects started to appear after 9 hours, due to the formation of AlON; and the interface between AlN and sapphire started to deteriorate, becoming unsuitable for growth.

This study also showed that when compared with constant temperature annealing, thermal cycling produces films in a shorter time with a lower threading dislocation density, while protecting the interface between AlN and sapphire.

For the range of thermal annealing conditions applied, the best results came from a five-cycle ramp between temperatures of 1600degC and 1700degC. With this approach, involving holding the sample for 72 minutes after each temperature change, the threading dislocation density fell to 1.65 x 108 cm-2.

According to the team, when the AlN film is simply annealed at 1700degC, the weak tensile strain relaxes, to leave almost no strain. By alternating temperatures between 1600degC and 1700degC, this allowed the lower temperature to induce compressive stress, which accelerates the movement of dislocations and ultimately increases the likelihood of annihilation and coalescence.

Using these conditions, but increasing the AlN film thickness to 800 nm, resulted in a further decrease in threading dislocation density to 8 x 107 cm-2.

The team has produced deep UV LEDs on this high-quality template, and for comparison, on a variant formed by MOCVD. Compared to the control, the multi-quantum wells in the low threading dislocation density templates had a dark spot density that is lower by almost an order of magnitude.

Output power for the device with the high-quality template is 80 percent higher. Further improvement in this figure is anticipated by optimising growth conditions, the substrate off-cut angle, and the hole injection layer.

D. Wang et al. Appl. Phys. Express 14 035505 (2021)