Novel epitaxy creates new phase of BiFeO3

Australian-US collaboration shows how stress enhances the properties of a promising material for future technologies

University of New South Wales (UNSW) researchers have found a new exotic state of the compound semiconductor BiFeO3 one of the most promising multiferroic materials, with exciting implications for future technologies using these enhanced properties.

Combining a careful balance of thin-film strain, distortion, and thickness, the team has stabilised a new intermediate phase in one of the few known room-temperature multiferroic materials.

The theoretical and experimental US-Australian study shows that this new phase has an electromechanical figure of merit over double its usual value, and that we can even transform between this intermediate phase to other phases easily using an electric field.

As well as providing a valuable new technique to the toolkit of all international material scientists working with multiferroics and epitaxy, the team say their results finally shed light on how epitaxial techniques can be used to enhance functional response of materials for future application in next -generation devices.

Stressed crystals

“In our research, we applied anisotropic strain to our film. This means that the strain applied is different depending on which direction you’re looking, and this can create complicated strain states that force films into new phases,” says first author Oliver Paull (UNSW).

BiFeO3 (or BFO) boasts an impressive resume of multifunctional properties, including piezoelectricity, ferroelectricity, magnetism, and optical properties.

BFO is arguably the most popular magnetoelectric material for researchers who are interested in using it for spintronics and memory applications since the coupling between magnetism and ferroelectricity promises low energy technologies.

Not only is BFO magnetoelectric, but it is one of the very few materials that is magnetoelectric at room temperature, making it viable for use in applications such as future low-energy electronics, without the requirement for energy-intensive cryo-cooling. Very few multiferroic materials exhibit these useful properties at room temperature.

By using highly miscut substrates, the research team pushed BFO into a new phase that is essentially the link between the well-known rhombohedral-like and tetragonal-like phases. This, coupled with the symmetry-related properties of the phase, allows it to be easily influenced by electric fields.

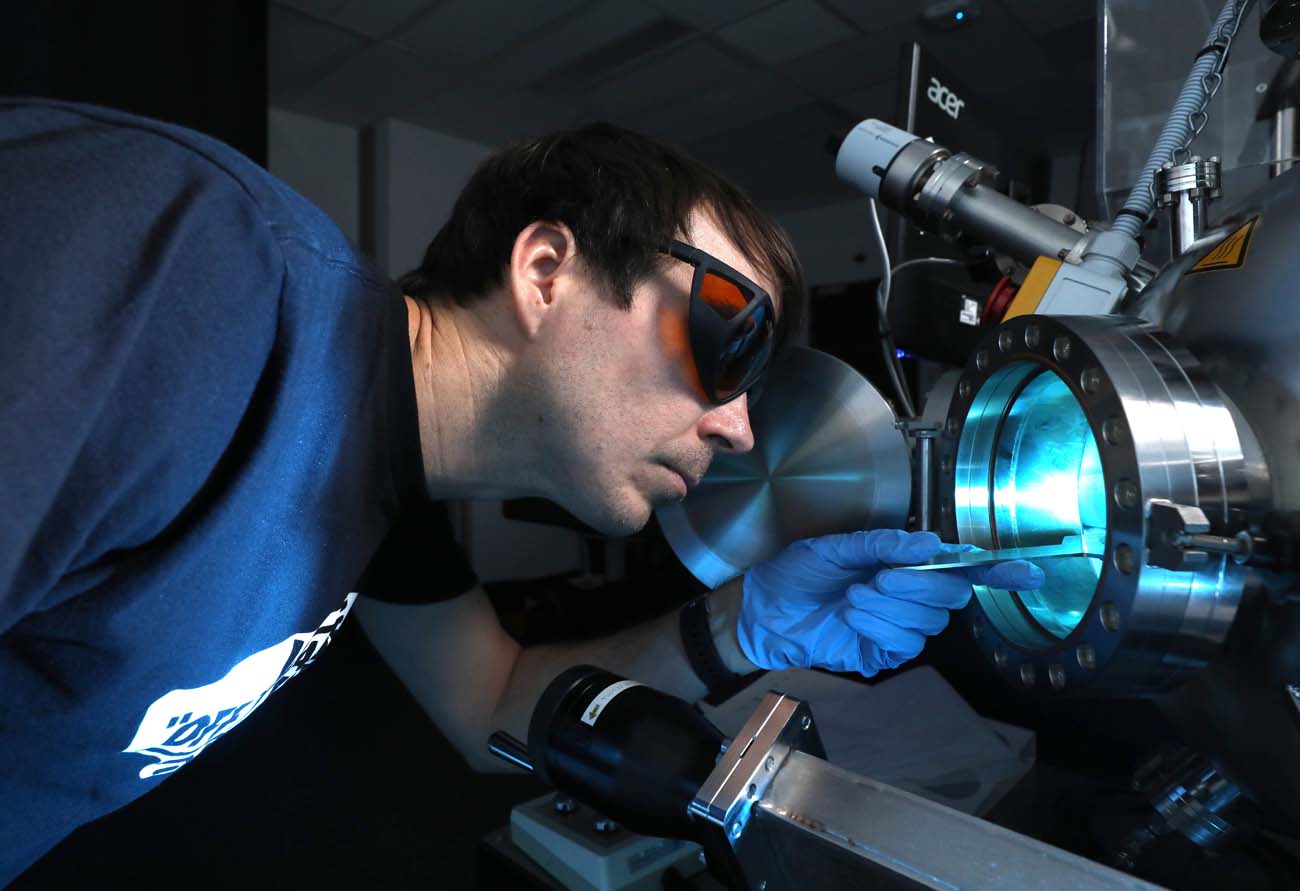

“We looked through the literature and found that everyone uses fairly standard commercial substrate orientations,” says head investigator Daniel Sando (pictured above). “We asked our providers to custom-make different miscut orientations in between the standard orientations, which led to the discovery of the new phase. We asked ourselves if the reason people hadn’t done this before is that the crystallography involved with these miscuts is rather complex and can be intimidating!”

Collaboration

The international collaboration between researchers at Oak Ridge National Lab, University of Arkansas, and Monash University, used theoretical calculations and a suite of experimental techniques to show that this new phase has a much higher electromechanical response than traditional BFO.

“We additionally show strong evidence that this low-symmetry phase can be converted into a higher-symmetry phase using an electric field, and as a result can enhance the electromechanical response even further by a factor of 3,” says Oliver Paull.

One of the most appealing aspects of this discovery is its general methodology and applicability to a broad class of materials systems.

“We chose to focus on BiFeO3 due to its ferroelectric, magnetic, and piezoelectric properties, but the approach is easily applied to other perovskite oxides,” says Paull.

“We are currently exploring the effect of these high-index substrates on purely ferroelectric or magnetic systems, but the scope for using this technique is huge. We expect to find low symmetry phases of optically interesting materials, as well as novel domain arrangements in ferroelectrics, to name a few,” noted Laurent Bellaiche, the theoretical lead on the project.”

Anisotropic Epitaxy

“If you’re dealing with epitaxy, then this anisotropic technique could prove very fruitful for your research,” says Sando.

“This study is just the beginning. We plan to combine this anisotropic epitaxy approach to oxide superlattices (repeating layers of different compositions, i.e. A-B-A-B etc.), as well as combining the low symmetry crystal structures with other established routes for improving piezoresponse, including substitution with rare earth elements, for example. Finally, since BFO is multiferroic, we have a raft of magnetic studies planned for this new low-symmetry phase.” Says UNSW lab leader Nagy Valanoor.

There are even broader possible applications: Piezoelectrics used in sensors and actuators are typically lead-based compounds in bulk form. While the new approach is niche and very research-oriented, there could be scope for the new methods to work in such industries as nano-actuators or sensors. The key aspect is the use of the anisotropic epitaxy approach to 1) generate a low-symmetry phase, and 2) facilitate enhancements in response; in this case, the piezoelectric coefficient.

'Anisotropic epitaxial stabilization of a low-symmetry ferroelectric with enhanced electromechanical response' by Daniel Sandoet al; Nature Materials, September 2020