Trumpf announces VCSEL heating systems

VCSEL heating systems for e-mobility accelerate sustainable battery production

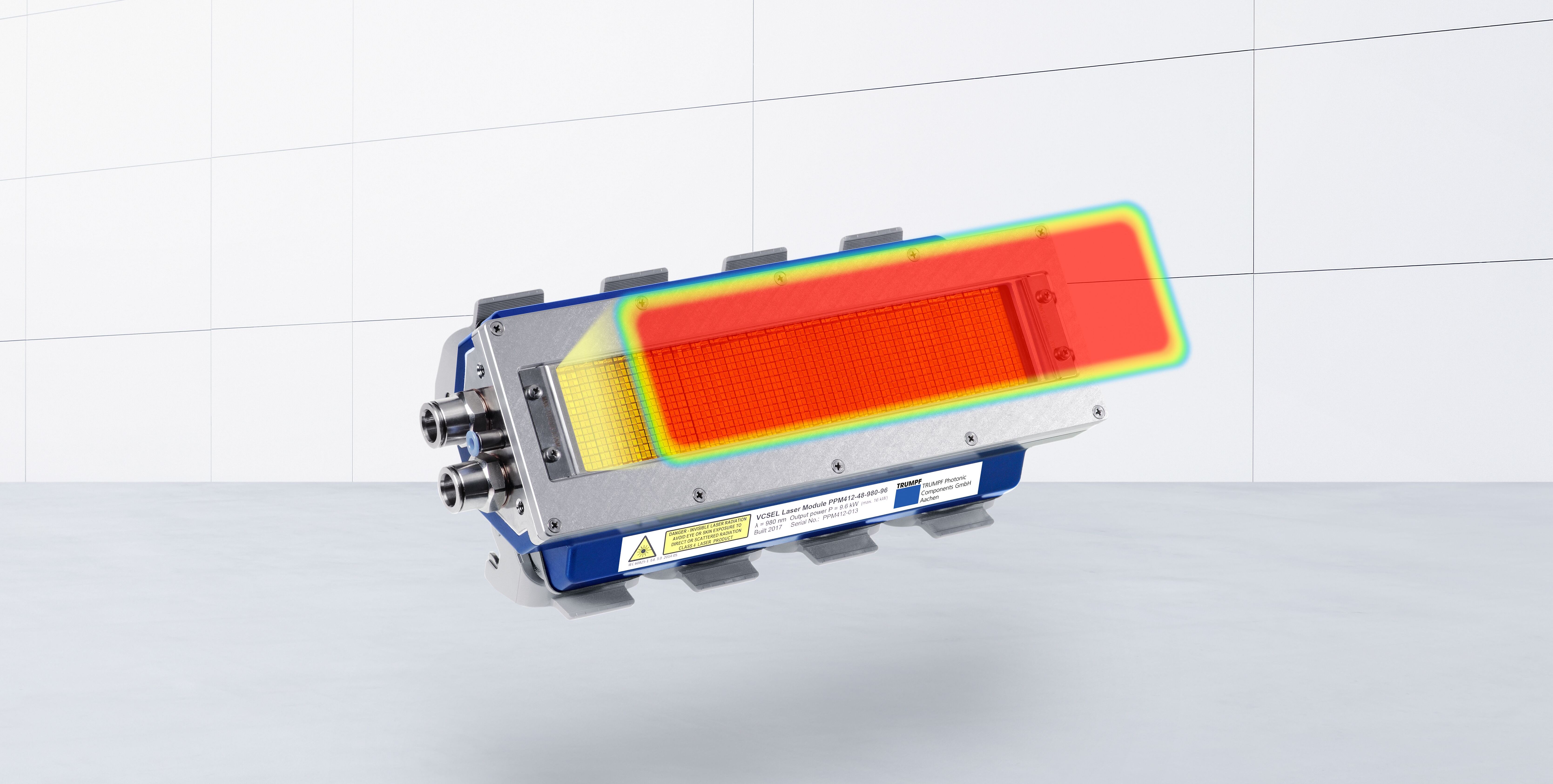

Trumpf Photonic Components is presenting its new VCSEL heating solutions for e-mobility at the Battery Show Europe in Stuttgart, offering various benefits in the manufacturing of Li-batteries.

In foil drying of batteries for e-cars, the VCSEL heating systems work with infrared radiation which directly transfer the heat to the application without any energy loss. This increases the efficiency of the battery process chain, according to Trumpf.

“E-mobility is targeting one of our main strategic growing business fields for our VCSEL heating systems and we are happy to contribute to the future of mobility with our solutions by enabling more efficient manufacturing”, says Ralph Gudde, VP marketing and sales at Trumpf Photonic Components.

Laser-based VCSEL arrays work very fast with directed optical infrared heating, in a defined manner to heat large areas. The VCSEL heating systems need less energy compared to standard ovens and allow a significant reduced footprint of the production system. The active material on the electrode foils can be dried efficiently to keep the solvent content as low as possible.

VCSEL heating systems can also extend lifetime of the battery cells, as they avoid wrinkles of the foils with a highly accurate sealing process. This leads to higher quality and homogeneity of the pouch cells, compared to other production methods such as welding with hot bars.

Furthermore, a VCSEL heating system is up to three times faster than hot bars. This increase in production speed is possible as the heat for welding is applied inside the pouch foil, close to the weld. To guarantee that only the foil seam is heated up, the clamping is out of sapphire components. Therefore, high quality welding results are achieved, as the clamping can be opened when the plastic of the foils is already solidified. This avoids defects of the weld seam, compared to other processes where the clamping has to be opened when the plastic is still in liquid state.

“Next to standard systems we also develop customized solutions. In our Customer Application Center in Aachen, we do have the infrastructure to run tests and evaluate the right solution with our customers”, says Gudde.