Perovskite-CIGS tandem is over 21 percent efficient

ZSW team's thin-film PV tandem technology can be deposited on plastic or steel films to make light, flexible modules

ZSW, the Centre for Solar Energy and Hydrogen Research Baden-Württemberg, has achieved 21.1 percent PV efficiency with a tandem of CIGS and perovskite. Not only are these thin-film-based modules highly efficient, they can also be light and flexible, according to ZSW.

The efficiency of the prevailing silicon cells is approaching the practical limit of around 27 percent. Tandem solar cells are the one technology that promises further increases by using different active layers working together to use more of the solar spectrum.

Metal-organic perovskites hold great promise for tandem solar modules. “Some compounds in this class of materials exhibit excellent optical and electronic properties and are abundantly and inexpensively available on Earth,” says Jan-Philipp Becker, head of ZSW’s Photovoltaics: Materials Research department. “With their high optical energy bandgap, compounds in the top solar module are able to use the high-energy range of the solar spectrum very efficiently. At the same time, they allow a considerable share of the spectrum’s low-energy range to pass through to the bottom solar module.”

Conventional silicon PV cells would appear to be the obvious choice for the bottom solar module. However, an even more interesting proposition is to use thin-film technologies exclusively. The bottom module can also be made of perovskite or of CIGS, which is the case in ZSW’s module. CIGS is a mix of materials – copper, indium and gallium vapour-deposited onto a rigid or flexible substrate in a selenium atmosphere.

The institute’s experts and industry partners had developed this technology and ramped it up for mass production in earlier projects. Usefully, CIGS’s spectral absorption can be tailored to a perfect fit for the tandem composite.

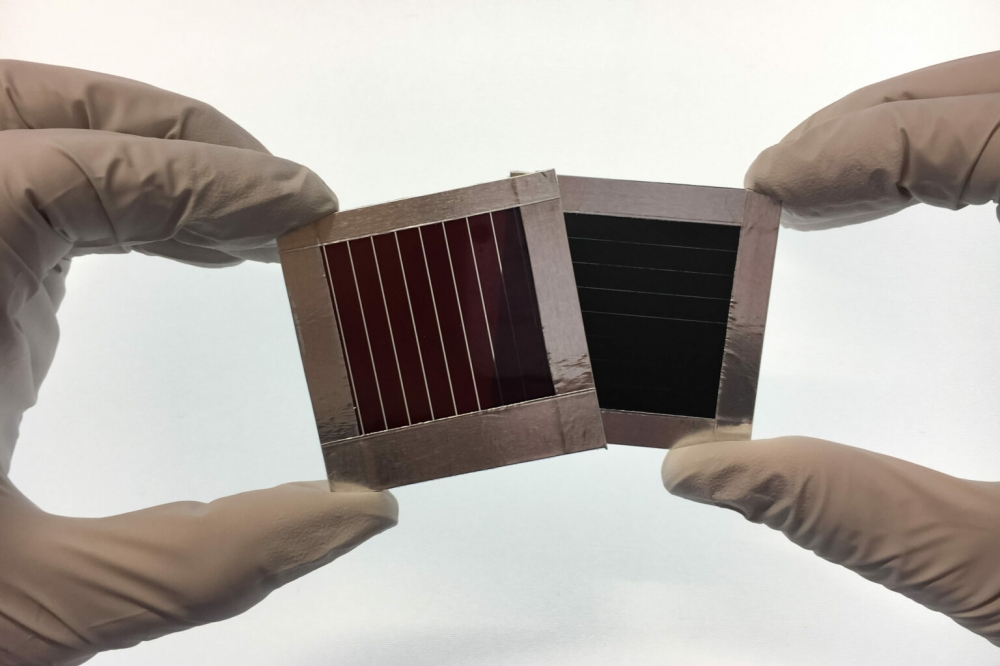

ZSW’s prototype tandem solar module has an area of 9cm2 and achieves 21.1 percent efficiency and it features scalable component architecture suitable for industrial manufacturing. The best performance attained to date with tandem solar modules made of perovskite and CIGS is just slightly higher at 22 percent. ZSW has already achieved an excellent efficiency level of 26.6 percent with this combination of materials in smaller laboratory cells.

To achieve these values, the top perovskite half-module not only has to be highly efficient; it must be semitransparent to allow enough light to pass through to the bottom module. To achieve this the developed more transparent electrodes and enhanced the passivation of boundary layers.

The tandem structure outperformed individual cells or modules in terms of efficiency. ZSW now aims to further scale up and develop tandem thin-film technology in a joint effort with interested industry clients.

Tandem solar cells that pair perovskite with CIGS offer benefits beyond high efficiency. This thin-film technology can also be deposited on plastic or steel films to make light, flexible modules that lend themselves to many more use cases. They can be installed the conventional way in solar parks and be seamlessly integrated into vehicles and on factory roofs that cannot handle heavy loads.

ZSW partnered with the Karlsruhe Institute of Technology (KIT) in this research initiative, which was part of the recently completed CAPITANO project funded by the German Federal Ministry of Economic Affairs and Climate Action (BMWK).