Perovskite solar cells tough enough to match silicon

Oxford University and Exciton Science show new way to create stable perovskite solar cells, with fewer defects

Researchers at Oxford University and Exciton Science have demonstrated a new way to create stable perovskite solar cells, with fewer defects and the potential to finally rival silicon’s durability.

By removing the solvent dimethyl-sulfoxide and introducing dimethylammonium chloride as a crystallisation agent, the researchers were able to better control the intermediate phases of the perovskite crystallisation process, leading to thin films of greater quality, with reduced defects and enhanced stability.

Large groups of up to 138 sample devices were then subjected to a rigorous accelerated ageing and testing process at high temperatures and in real-world conditions.

Formamidinium-caesium perovskite solar cells created using the new synthesis process significantly outperformed the control group and demonstrated resistance to thermal, humidity and light degradation.

This is a strong step forward to matching commercial silicon’s stability and makes perovskite-silicon tandem devices a much more realistic candidate for becoming the dominant next-generation solar cell.

Led by Henry Snaith (Oxford University) and Udo Bach (Monash University), the work has been published in the journal Nature Materials.

Oxford University PhD student Philippe Holzhey, joint first author on the work, said: “It's really important that people start shifting to realise there is no value in performance if it's not a stable performance.

“If the device lasts for a day or a week or something, there's not so much value in it. It has to last for years.”

During testing, the best device operated above the T80 threshold for over 1,400 hours under simulated sunlight at 65°C. T80 is the time it takes for a solar cell to reduce to 80 percent of its initial efficiency, a common benchmark within the research field.

Beyond 1,600 hours, the control device fabricated using the conventional dimethyl-sulfoxide approach stopped functioning, while devices fabricated with the new, improved design retained 70% of their original efficiency, under accelerated aging conditions.

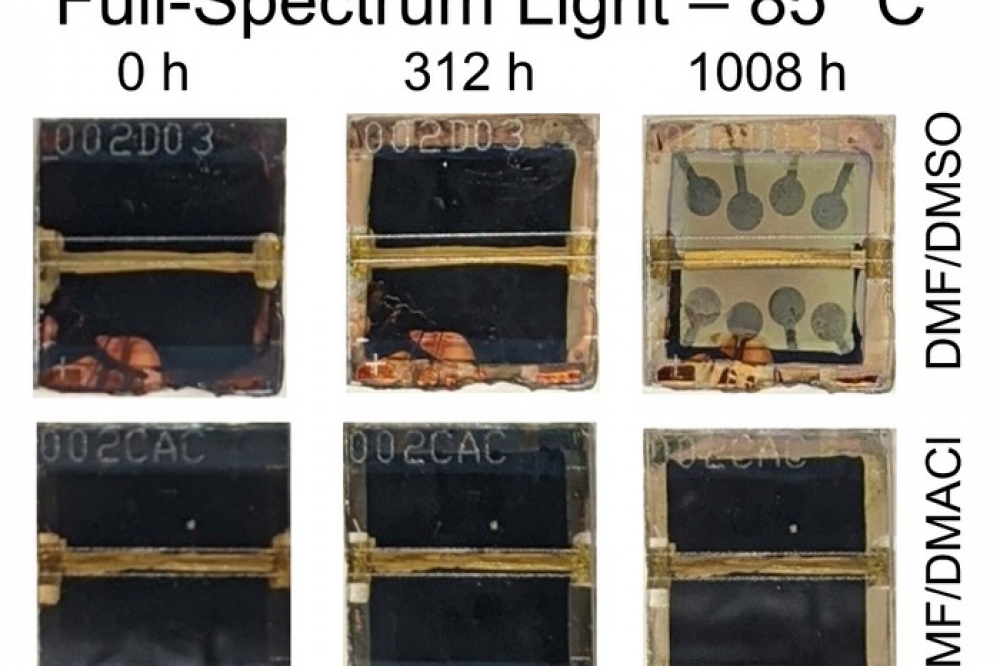

The same degradation study was performed on a group of devices at the very high temperature of 85°C, with the new cells again outperforming the control group.

Extrapolating from the data, the researchers calculated that the new cells age by a factor of 1.7 for each 10°C increase in the temperature they are exposed to, which is close to the 2-fold increase expected of commercial silicon devices.

David McMeekin, the corresponding and joint first author on the paper, said: “I think what separates us from other studies is that we've done a lot of accelerated aging. We've aged the cells at 65°C and 85°C under the whole light spectrum.”

The number of devices used in the study is also significant, with many other perovskite research projects limited to just one or two prototypes.

“Most studies only show one curve without any standard deviation or any kind of statistical approach to determine if this design is more stable than the other,” he added.

The researchers hope their work will encourage a greater focus on the intermediate phase of perovskite crystallisation as an important factor in achieving greater stability and commercial viability.

This work was supported by the Stanford Linear Accelerator Center (SLAC) and the National Renewable Energy Laboratory (NREL).

Reference

'Intermediate-phase engineering via dimethylammonium cation additive for stable perovskite solar cells' by David P. McMeekin et al; Nature Materials (2022)