Researchers develop novel sticky tape for 2D materials

UV-sensitive tape can transfer 2D materials in an easier, cheaper and less-damaging way

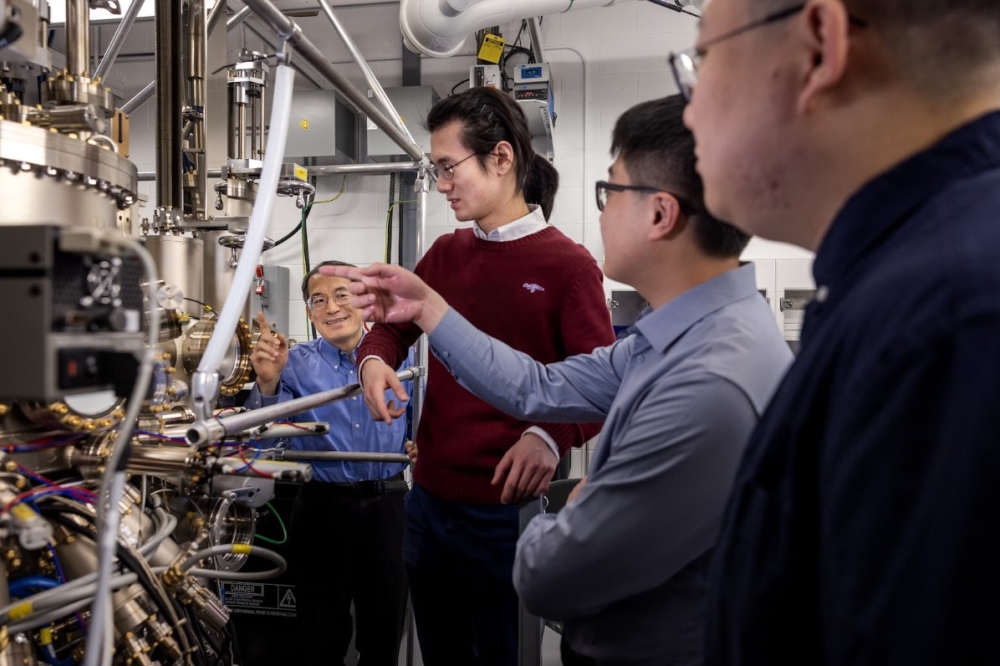

A research team from Kyushu University, in collaboration with Japanese company Nitto Denko, has developed a polymer tape that can be used to stick 2D materials to many different surfaces, in an easy and user-friendly way.

The scientists call their innovation 'UV tape', because it changes its attraction to materials when irradiated with UV light.

Their findings were published in Nature Electronics on February 9, 2024 in the paper 'Ready-to-transfer two-dimensional materials using tunable adhesive force tapes'.

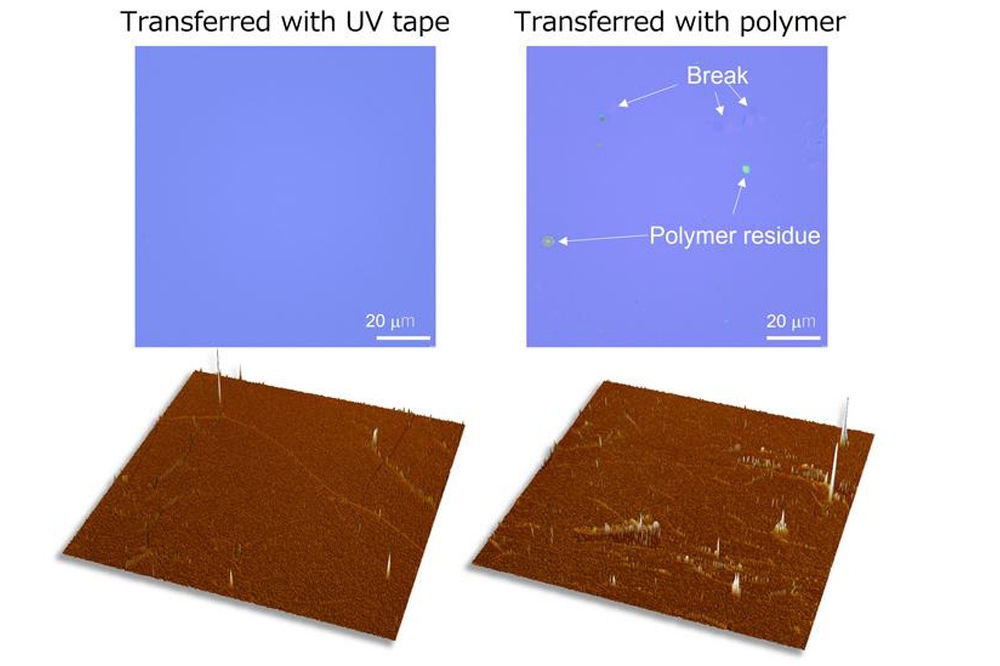

“Transferring 2D materials is typically a very technical and complex process; the material can easily tear, or become contaminated, which significantly degrades its unique properties,” says lead author, Hiroki Ago of Kyushu University's Global Innovation Center. “Our tape offers a quick and simple alternative, and reduces damage.”

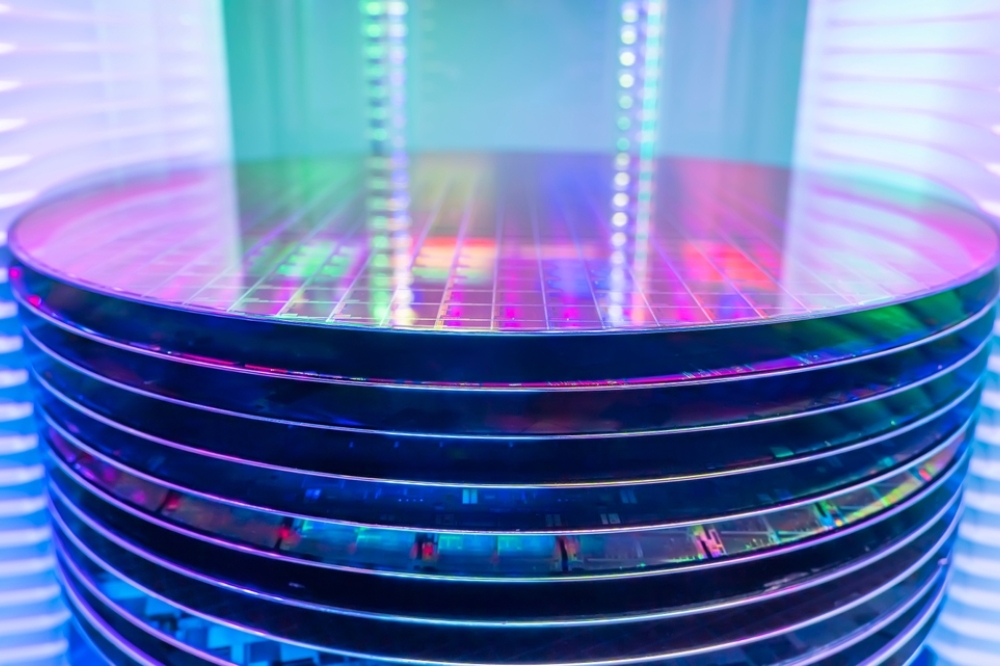

The researchers began by focusing on graphene, and then developed tapes able to transfer white graphene (hBN), and transition metal dichalcogenides (TMDs), which are promising materials for next generation compound semiconductors.

When the researchers looked closely at the surface of the 2D materials after transfer, they saw a smoother surface with fewer defects than when transferred using the current conventional technique. Upon testing the materials’ properties, they also found that they were more efficient.

Before exposure to UV light, the tape has a strong adhesion to the 2D material, allowing it to “stick”. After UV exposure, the atom bonding changes, which decreases the level of adhesion. The UV tape also becomes slightly stiffer and easier to peel off. Taken together, these changes allow the tape to be peeled off the device substrate while leaving the 2D material behind.

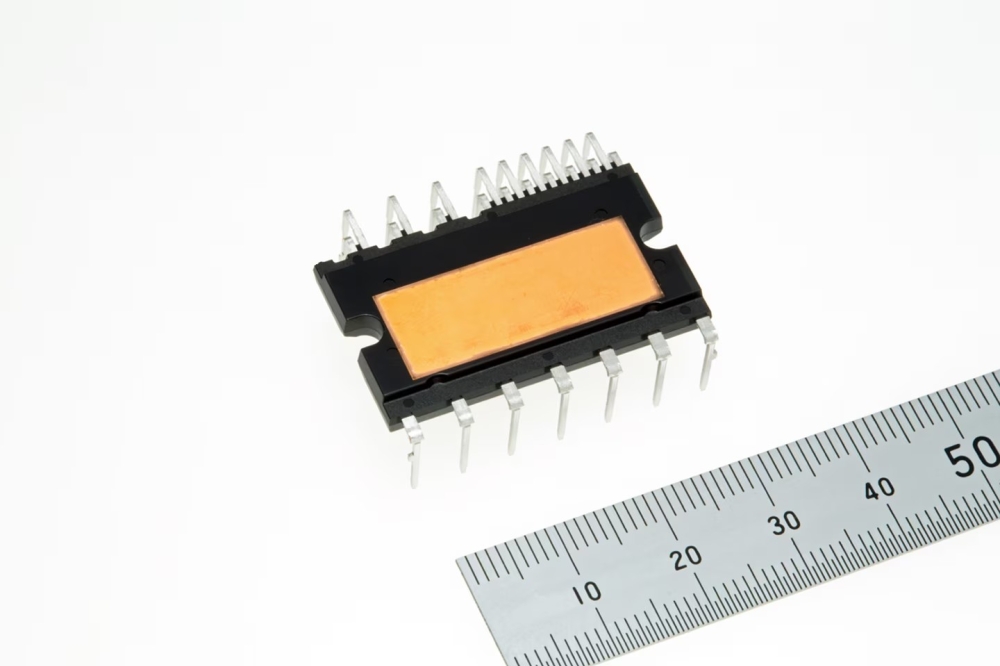

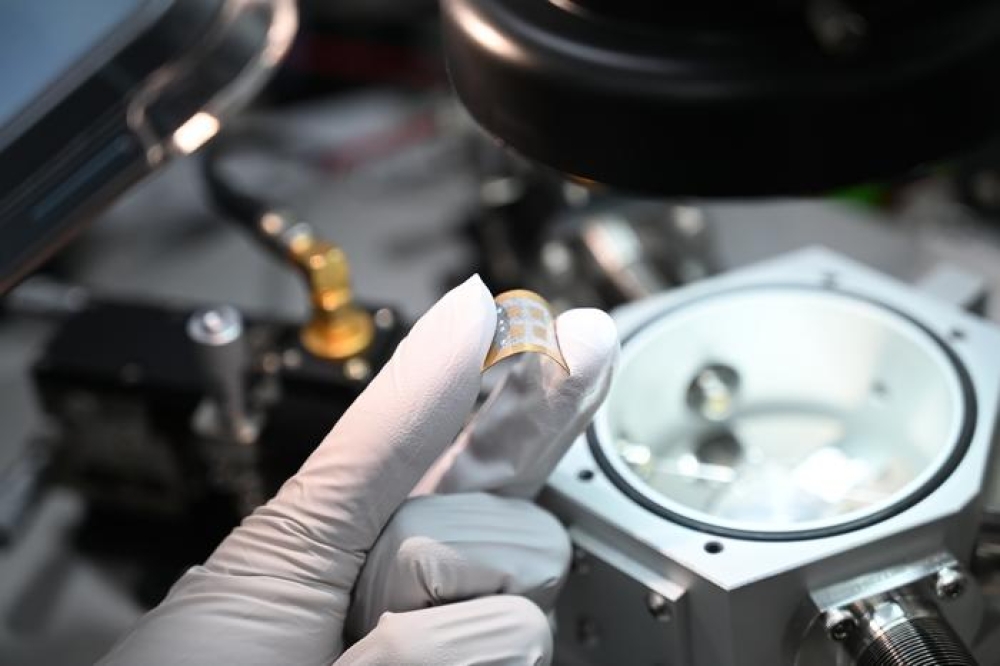

The team says that transfer using UV tape also offers numerous other advantages over current transfer techniques. Because the UV tape is bendy, and the transfer process doesn’t require the use of plastic-dissolving solvents, flexible plastics can be used as the substrate of the device, expanding potential applications.

“For example, we made a plastic device that uses graphene as a terahertz sensor. Like X-rays, terahertz radiation can pass through objects that light can’t, but doesn’t damage the body,” Ago says. “It’s very promising for medical imaging or airport security.”

The UV tape can be cut to size so that only the exact amount of 2D material needed is transferred. 2D layers of different materials can also be easily laid on top of each other in different orientations, allowing researchers to explore new emerging properties from the stacked materials.

For their next steps, the researchers are aiming to expand the size of the UV tape to the scale needed for manufacturers.

The research team also hopes to improve stability, so that 2D materials can be attached to UV tapes for a longer period of time, and distributed to end users, such as other scientists.

“The end users can then transfer the material onto their desired substrate by applying and removing the UV tape like a child’s sticker, with no training needed,” says Ago. “Such an easy method could fundamentally change the style of research and accelerate the commercial development of 2D materials.”