NREL outlines way forward for tandem cells

Tandem tech will help us reach 75 terawatts of PV by 2050, say researchers, but industry collaboration will be key

Researchers at the US Department of Energy’s National Renewable Energy Laboratory (NREL) have prepared a roadmap on how to move tandem solar cells—particularly those that mesh different photovoltaic technologies—closer to commercialisation.

As the researchers pointed out in a recently published article in the journal Joule, considerably more solar power must be added globally beyond the currently installed 1 terawatt of capacity. Because of the growing population and increased electrification of all energy sectors, experts are predicting the world will need 75 terawatts of photovoltaics (PV) by 2050.

The vast majority of solar modules in use today rely on a single junction, which is able to absorb only a fraction of the solar spectrum and thus are limited to how efficient they can be. Tandem solar cells hold the potential to reach much higher efficiencies.

Kirstin Alberi, the lead author of the journal article, titled 'A Roadmap for Tandem Photovoltaics' said high-efficiency III-V multijunction solar cells have been available for decades but at small scales and primarily for space applications such as to power satellites. Alberi, director of the Materials Science Center at NREL, said newer types of hybrid tandem modules using more scalable PV technologies are now in development by both major manufacturers and startup companies “but we are not aware of any that are being mass-produced and sold commercially.”

Alberi and her 17 coauthors from the Department of Energy-funded laboratory are attempting to spur researchers and manufacturers to collaborate with a goal of making rapid progress toward mass production of tandems.

They spelled out the advances that must be made:

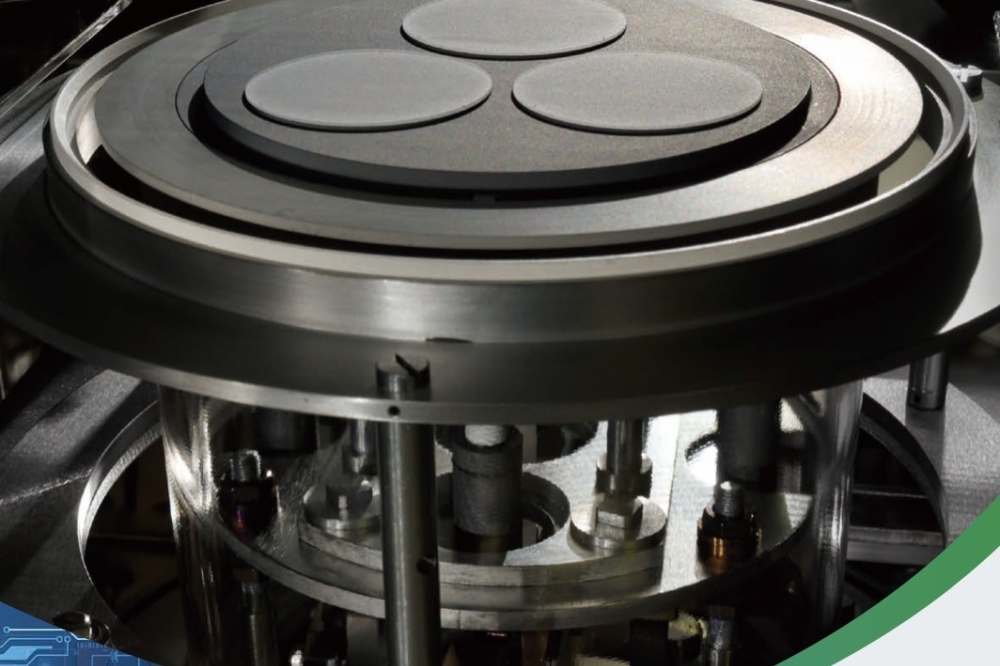

- Increase the efficiency of solar cells to record levels, and then translate those efficiencies to modules and high-volume manufacturing

- Identify and address reliability and durability issues

- Work out the design of hybrid tandem PV modules and systems to speed deployment.

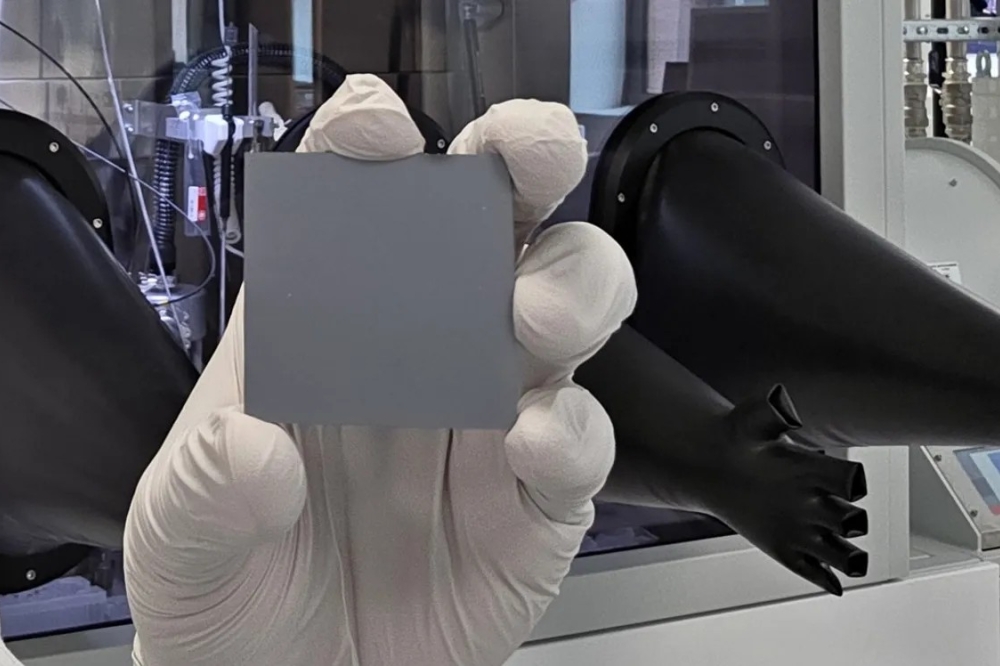

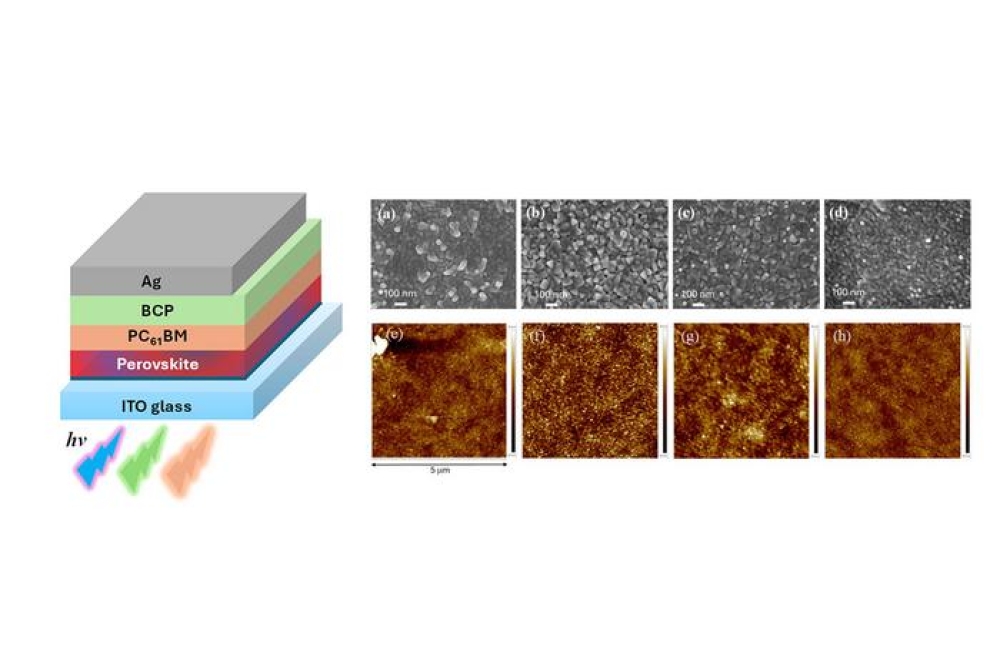

The roadmap focuses on hybrid tandems, where two or more different PV technologies are combined to provide the maximum efficiency. These materials are divided into two groups: those best as top cells and those best as bottom cells. The correct match between the two junctions increases the amount of sunlight that is absorbed and converted into electricity. A top solar cell made of metal halide perovskites, for example, could boost the performance of a single junction silicon solar cell.

“Metal halide perovskites are viewed as an initial enabler of hybrid tandems from a cost and efficiency perspective,” Alberi said. “They provide high enough efficiencies as a top cell and are also cost effective enough to incorporate that the tandem would have much higher efficiencies than the single-junction cells of either technology.”

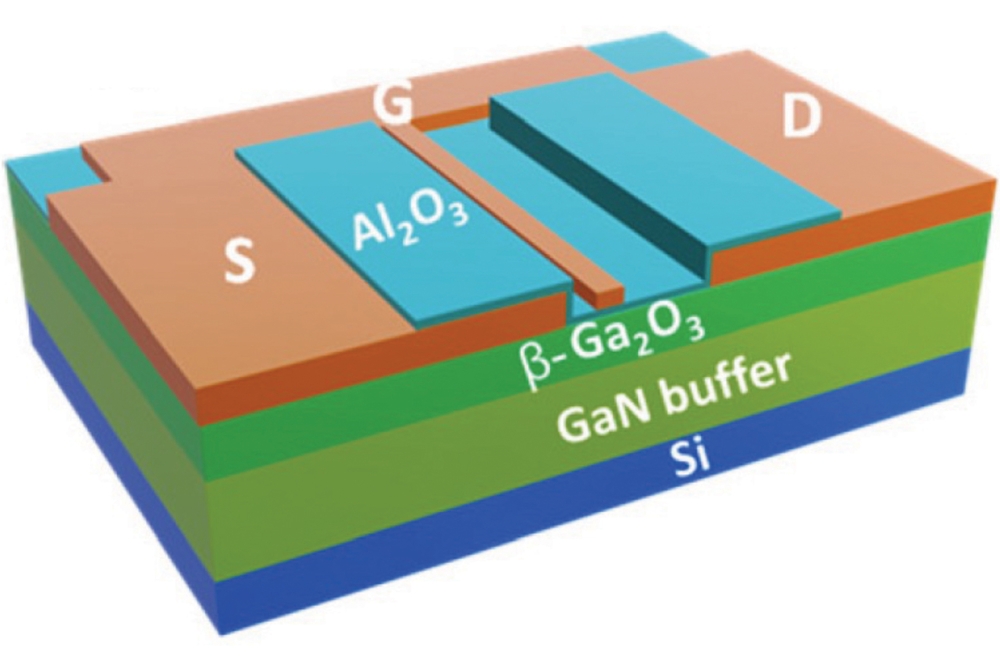

The tandem roadmap advocates considering the potential of other materials as a top cell. GaAs and GaInP are both candidates as they have the highest efficiency of single-junction devices. The main drawback to their use, however, is the expense to make. Researchers at NREL have been looking into cheaper manufacturing methods.

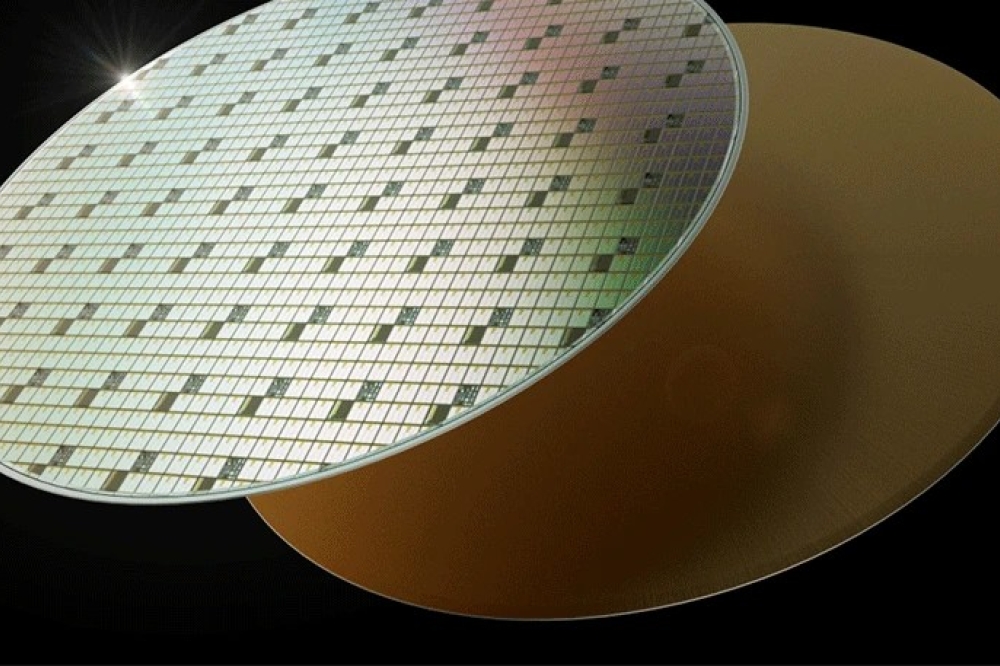

The obvious material for a bottom cell, the researchers said, is silicon, which dominates the solar industry. A tandem made of a top metal halide perovskite cell and a bottom silicon cell currently holds the record for efficiency.

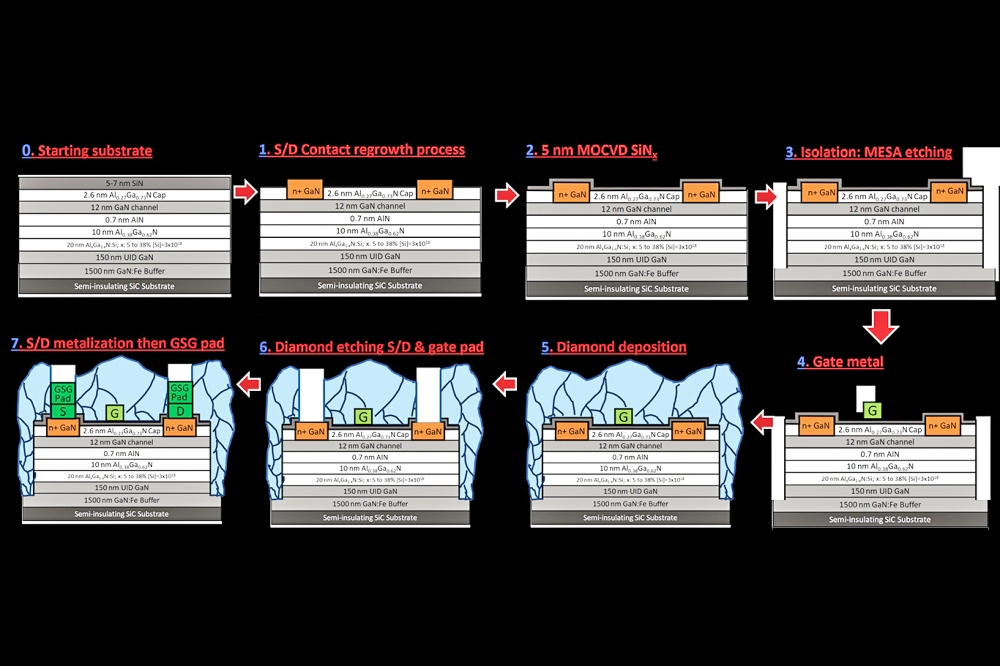

A tandem comes with additional challenges, said Emily Warren, a staff scientist in the High-Efficiency Crystalline Photovoltaics group at NREL and a coauthor of the roadmap paper.

“For single-junction PV materials, modules are made by interconnecting individual cells laterally in series,” she said. “For tandems, there are multiple options to interconnect the cells, which provides another layer of complexity to the design of tandem modules.”

Only three single-junction PV technologies have successfully been scaled to at least a gigawatt of production. In addition to silicon, inroads have been made by solar cells made from CIGS and from CdTe. CIGS is suitable for a bottom cell and CdTe as a top.

The researchers said the contrast in the commercialisation trajectories between silicon and the thin-film cells made of CIGS and CdTe offers insight into the challenges that must be overcome to establish a gigawatt-scale tandem technology.

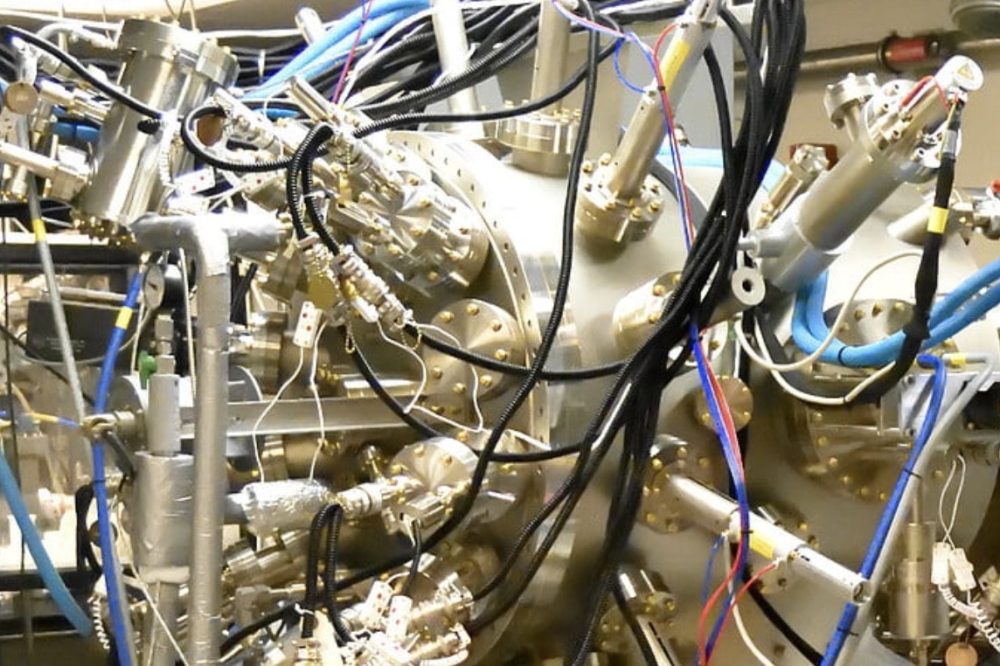

Silicon PV benefited from major investments by the semiconductor community, resulting in shared knowledge and standardised processes. Companies specialising in CIGS and CdTe, however, have carefully guarded their processes and deposition techniques as they attempt to make headway against silicon PV.

The roadmap proposes a collaborative effort, such as a consortium similar to those that have been created to boost the manufacturing of perovskites and of CdTe solar panels. This would bring industry and researchers together “to discuss common issues and share lessons learned,” according to the roadmap paper. Some consortia are already working on perovskite-based tandems.

“Existing consortia have proven to be immensely helpful in the development and commercialisation of single-junction PV technologies because they can help in information sharing, advocating for cross-cutting research that will help the field as a whole, and focusing larger sets of stakeholders to work together to solve problems that impact the entire field,” Alberi said. “We think consortia could serve a similar role in the development of hybrid tandems, particularly because we are still early in the commercialisation phase of this technology.”