Morgan and Penn State sign SiC partnership

In five year R&D agreement, Morgan will supply materials and solutions for new SiC crystal growth facility

Morgan Advanced Materials and Penn State University in the US have signed a new five-year Memorandum Of Understanding to further enhance their partnership.

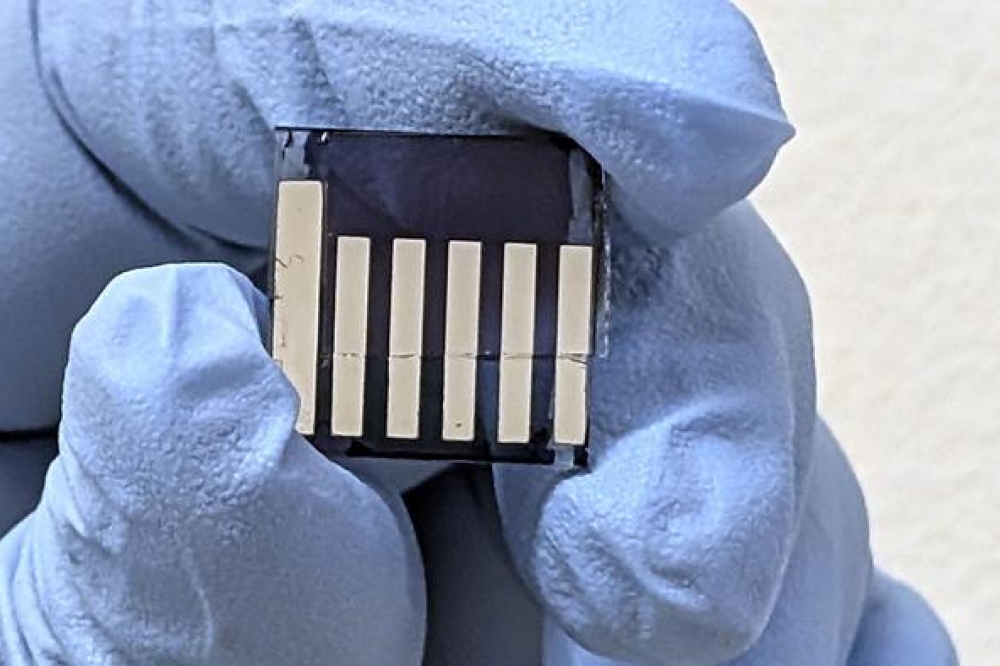

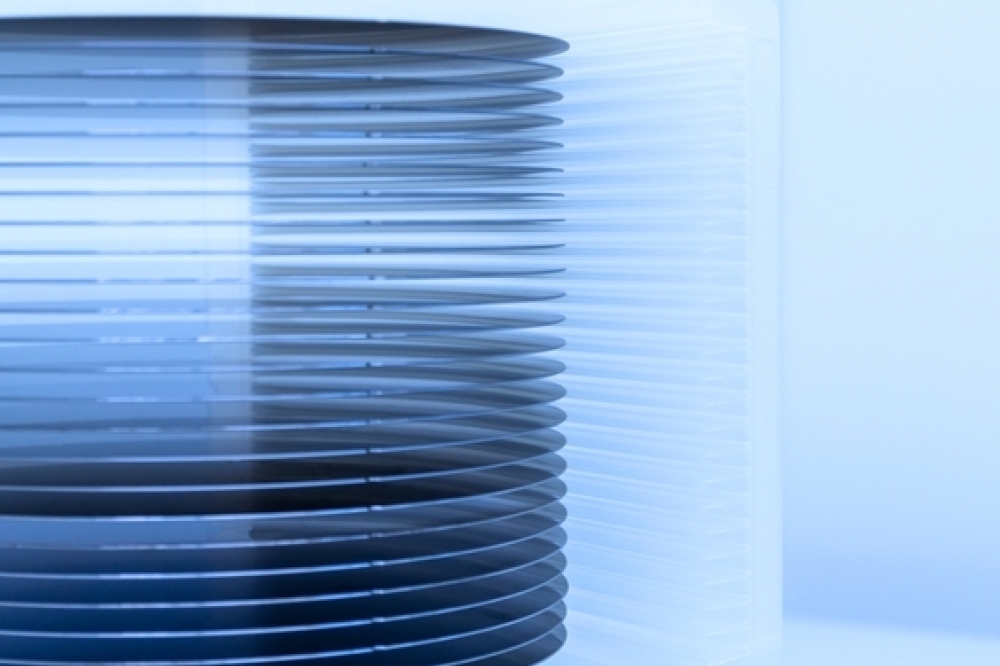

The agreement is focused on research and development in SiC crystal growth. With this agreement, Morgan has pledged to become a founding member of the recently launched SiC Innovation Alliance (SCIA) and to supply graphite materials and solutions to the new SiC crystal growth facility for use by internal and external partners.

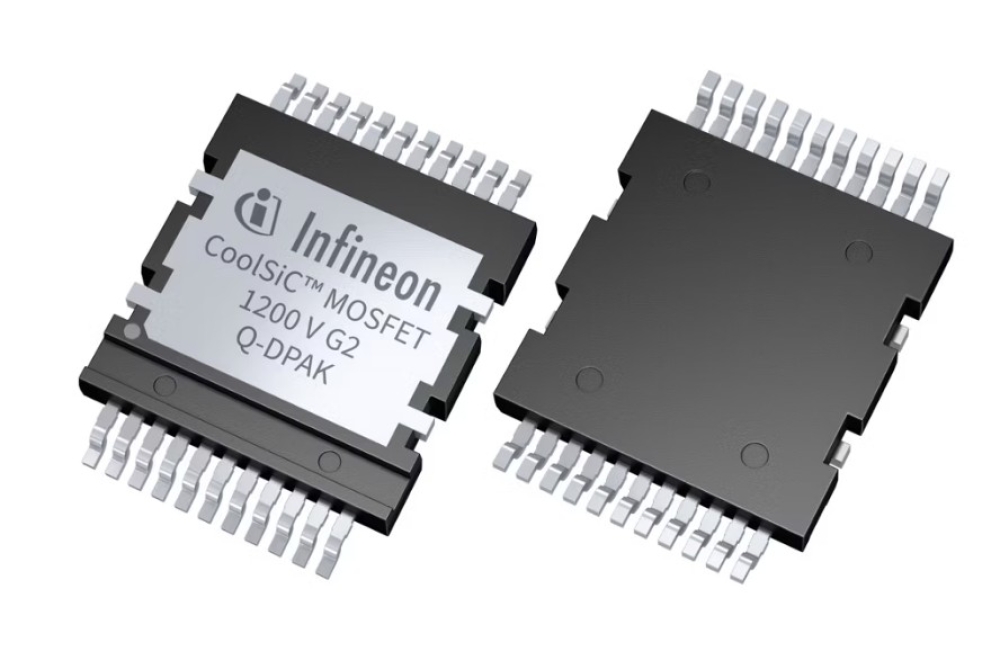

The SiC Innovation Alliance (SCIA) is a coalition of industry leaders, academic institutions and government support with a focus on becoming a central hub for research, development and workforce training in SiC semiconductor technologies.

The flagship of the alliance will be the new ‘Onsemi SiC centre (SiC3)’ which is expected to be fully operational by the beginning of 2025. It will house a pilot-scale facility that will include two Physical Vapour Transport (PVT) furnaces and will emulate the entire SiC semiconductor value chain.

“We are very excited to have Morgan as a founding member in the initiative, partnerships like this will maximise our impact in next generation SiC crystal research and workforce development.” Joshua Robinson, professor of materials science and engineering and acting associate dean for research in the College of Earth and Minerals Sciences.

Morgan Advanced Materials has been manufacturing carbon and graphite-based materials essential for growing SiC crystals since the 1990s, and has several collaborations existing with Penn State researchers. “The new agreement with Penn State seamlessly aligns our goal of establishing Morgan as a key player in the SiC semiconductor market – we are not only advancing our own graphite competencies but also contributing to the development of high-value products in the market” said Thomas Connolly, CTO at Morgan.