$23.9M CHIPS Act funding for space solar cells

New Mexico-based Rocket Lab USA has signed a preliminary agreement with the US Department of Commerce to receive up to $23.9M in direct funding under the CHIPS and Science Act.

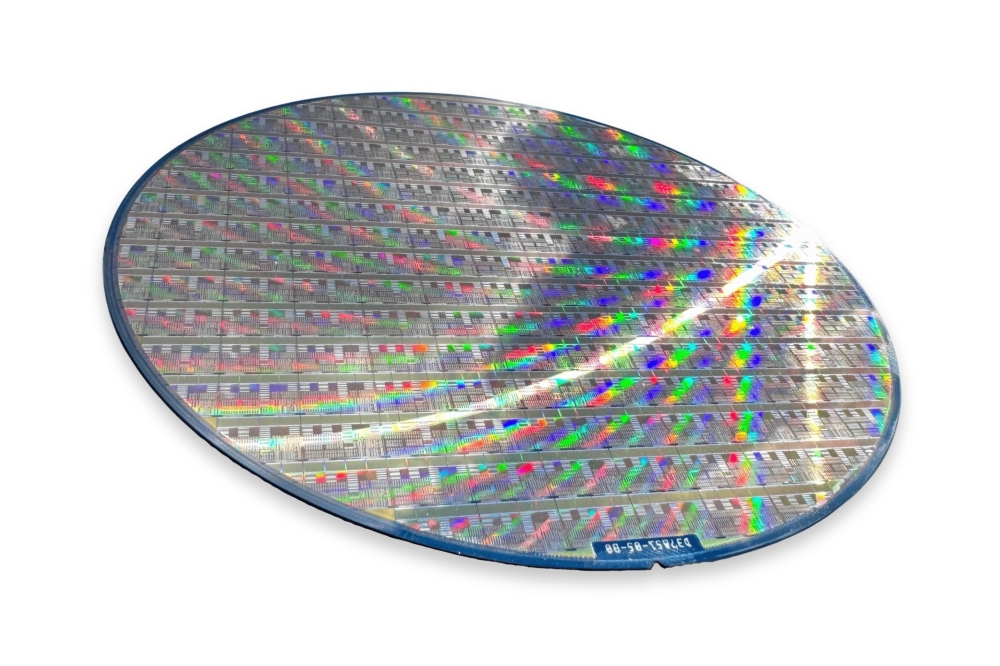

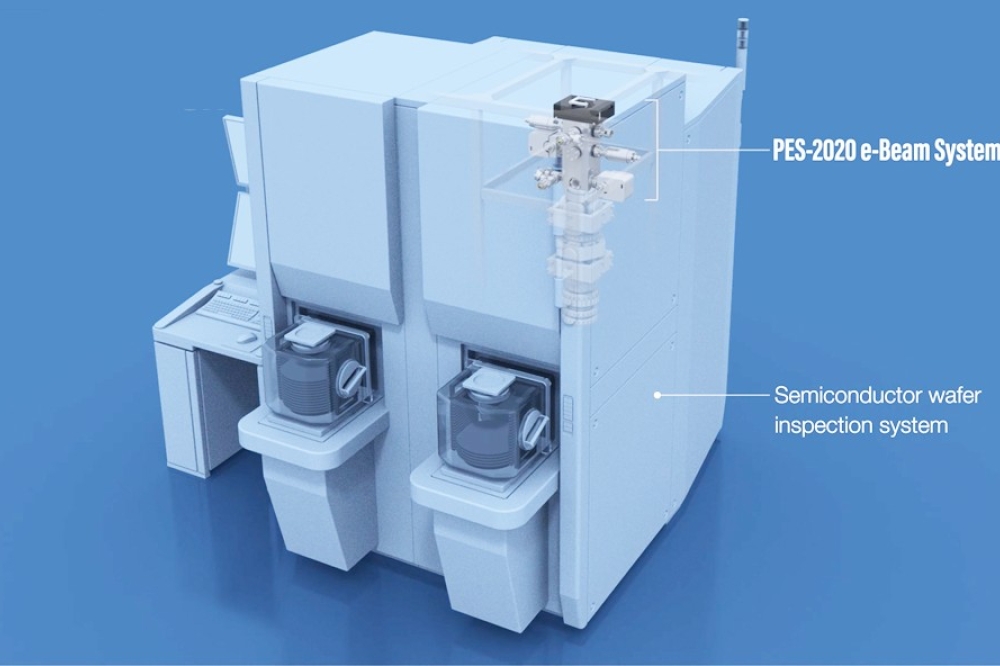

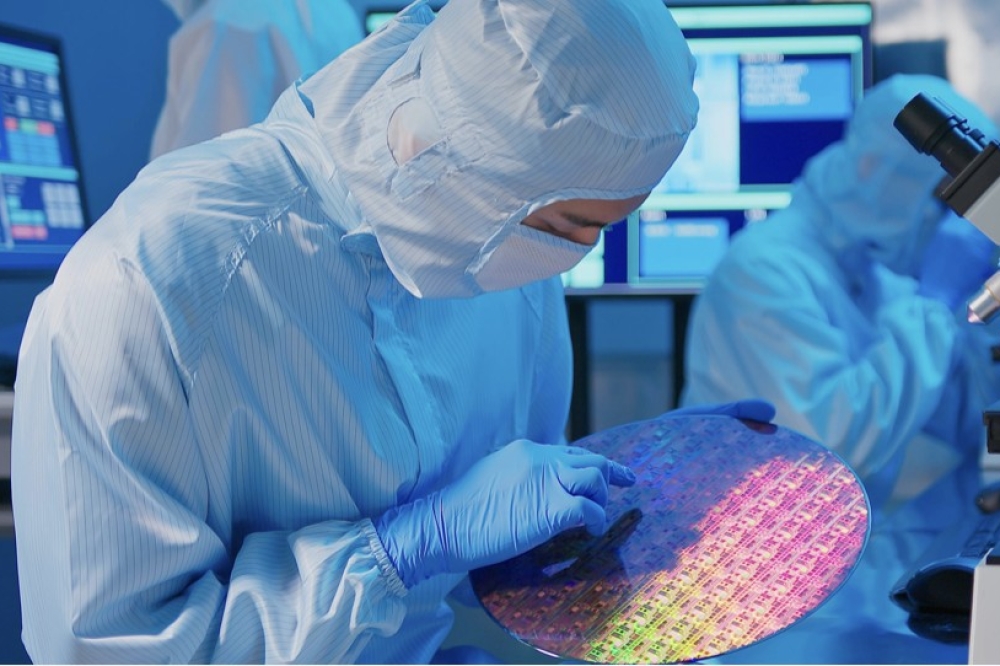

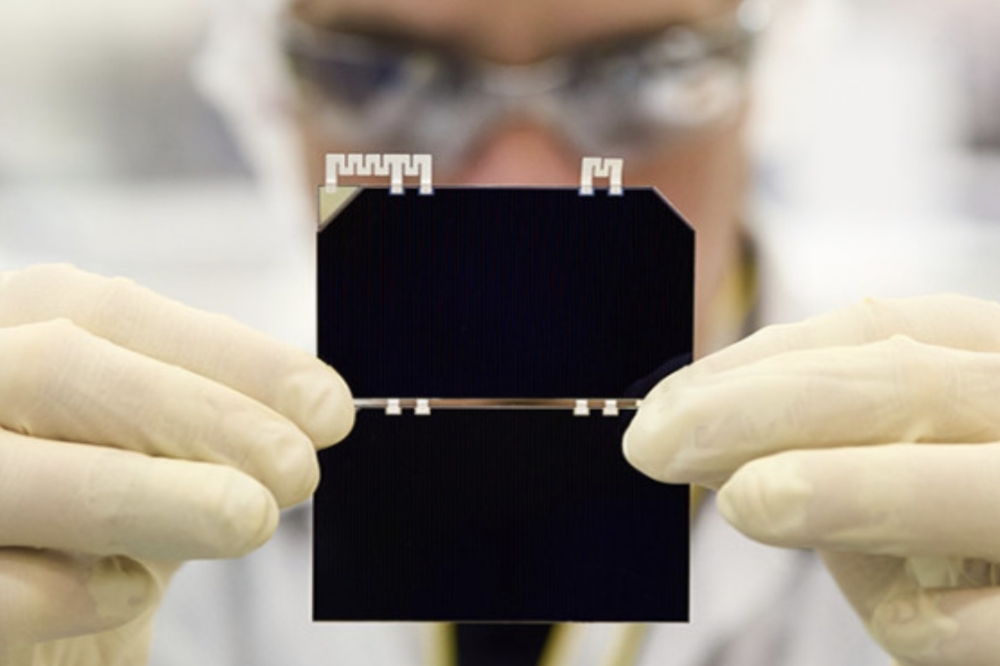

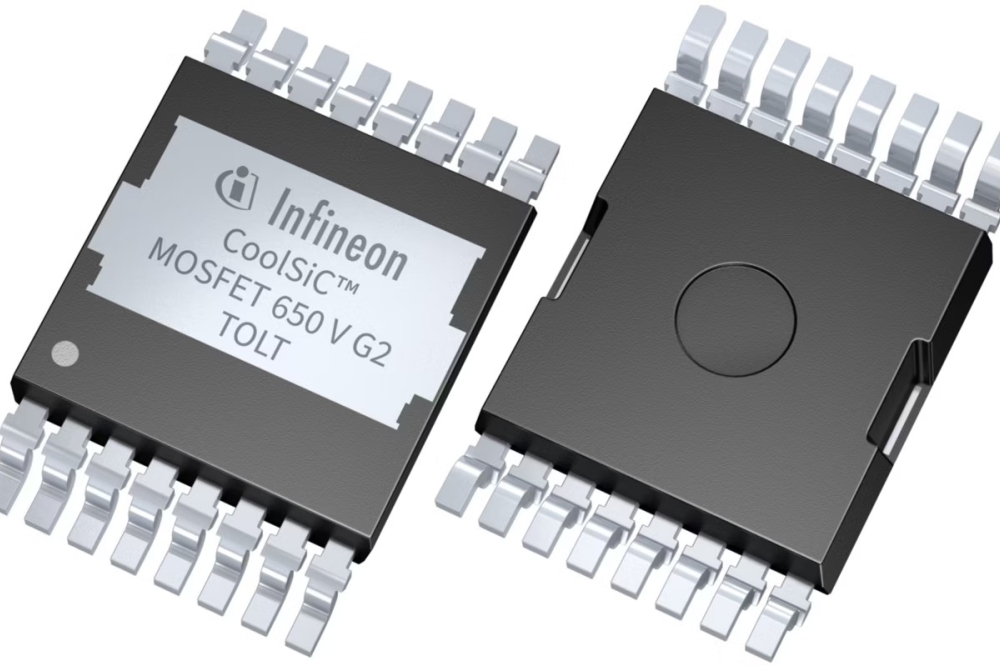

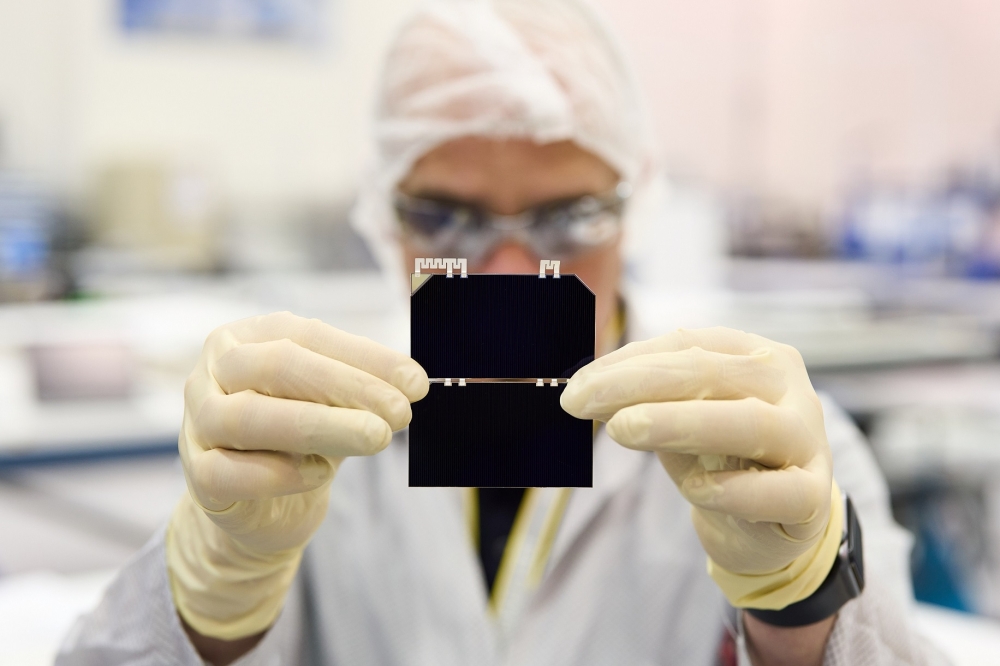

The proposed investment would enable Rocket Lab to increase its production of compound semiconductor-based solar cells for spacecraft and satellites, as part of an expansion and modernisation of the company’s facility in Albuquerque.

It would also help create a more robust and resilient supply of space-grade solar cells, by increasing Rocket Lab’s compound semiconductor production by 50 percent within the next three years.

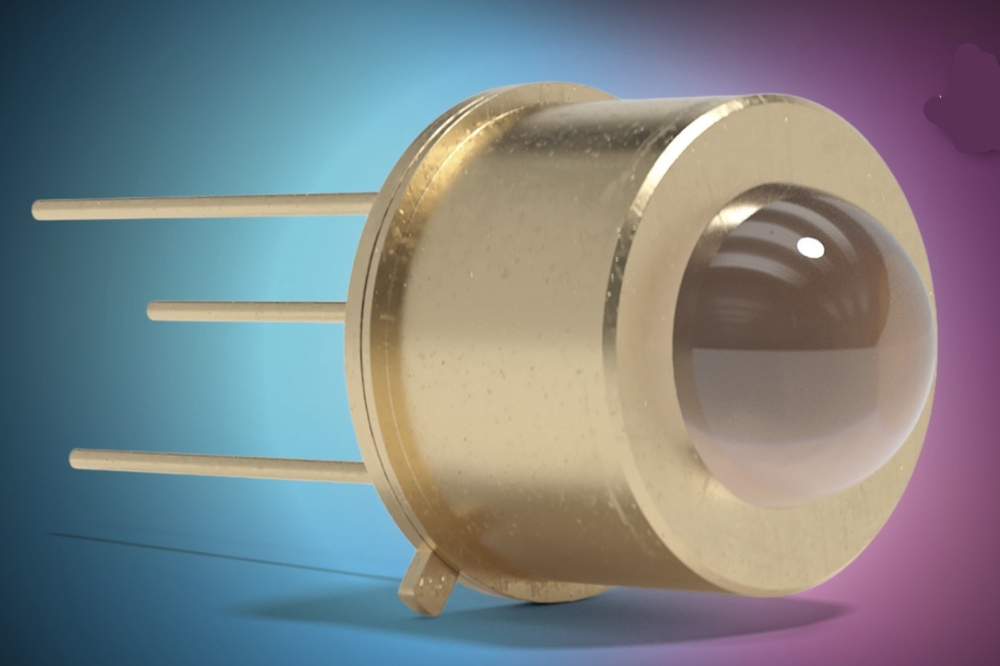

When Rocket Lab acquired SolAero Technologies Inc in 2022, it became one of only two companies in the US, and three companies outside of Russia and China, that specialises in the production of radiation resistant space-grade solar cells.

The solar cells produced at Rocket Lab’s facility power missions including the James Webb Space Telescope, NASA’s Artemis lunar explorations, Ingenuity Mars Helicopter, and the Mars Insight Lander. Rocket Lab's technology also serves a booming commercial satellite market, such as powering the OneWeb broadband internet satellite constellation.

In addition to these proposed federal incentives, the State of New Mexico has also committed to providing financial assistance and incentives with a total value of $25.5 million to Rocket Lab in support of this effort.

"Semiconductors are central to modern life, to our economy, and to America's future. We are proud to be strengthening that future with the support of the CHIPS Office by expanding our production facilities to meet growing demand for the semiconductors that power the nation's most critical science, defense and commercial space missions," said Rocket Lab founder and CEO, Sir Peter Beck. "For more than two decades the SolAero team, now part of Rocket Lab, has played a crucial role in the domestic production of semiconductors. This program is a continuation of our commitment to ensuring resilient US. supply chains and creating highly productive local jobs."