Hofer and ETH Zurich begin GaN inverter project

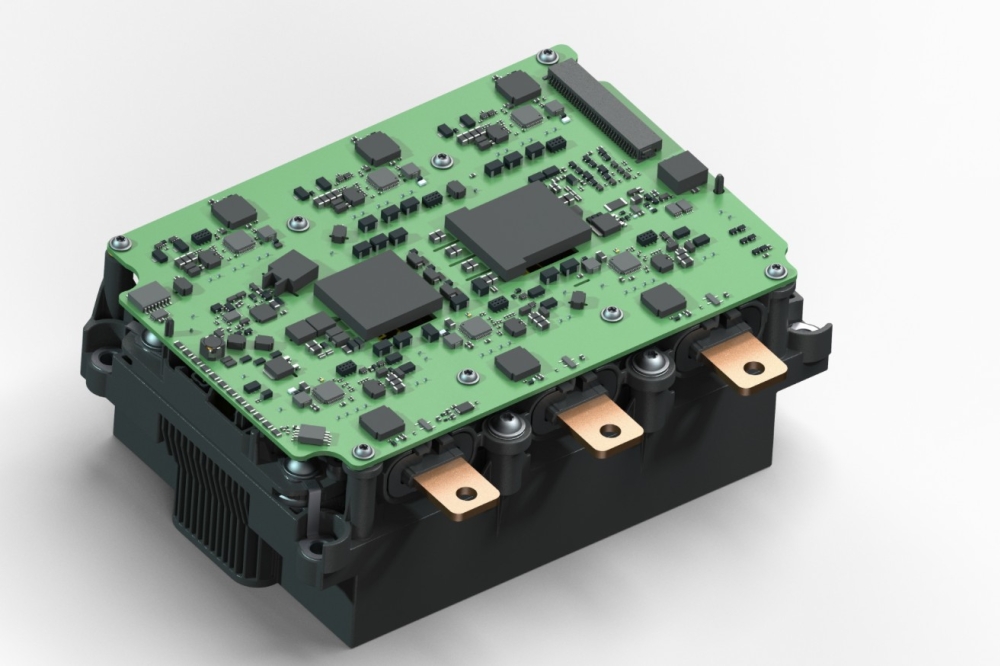

Hofer Powertrain has announced the start of a research project in collaboration with the Swiss Federal Institute of Technology in Zurich (ETH Zurich), focusing on the development of a state-of-the-art multilevel GaN traction inverter.

It is supported by funding from INNOSUISSE, the Swiss Agency of Innovation Promotion, which advances science-based innovations in the interest of the economy and society in Switzerland.

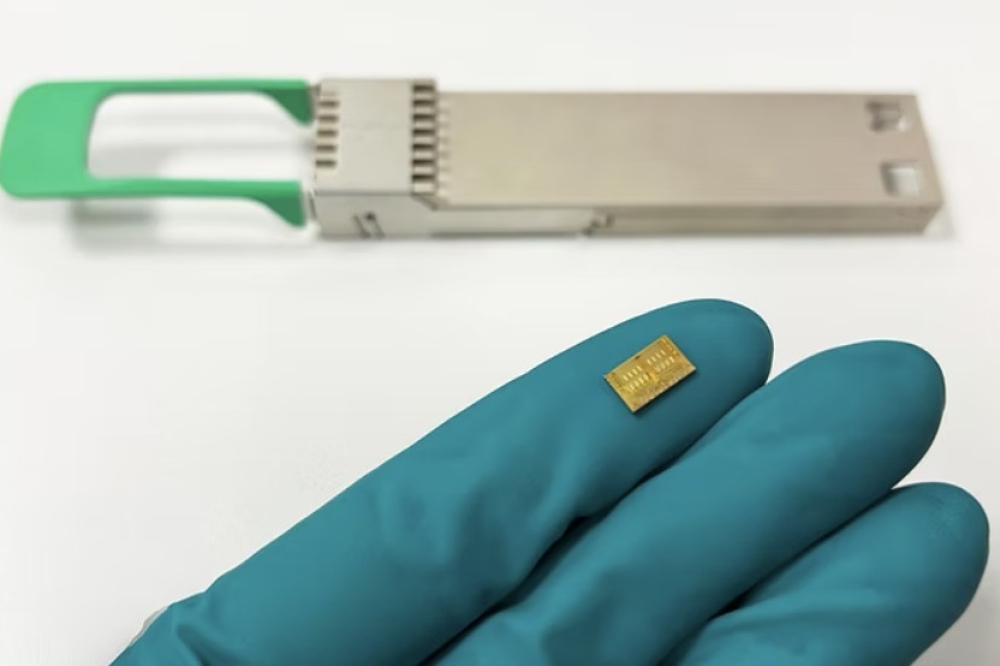

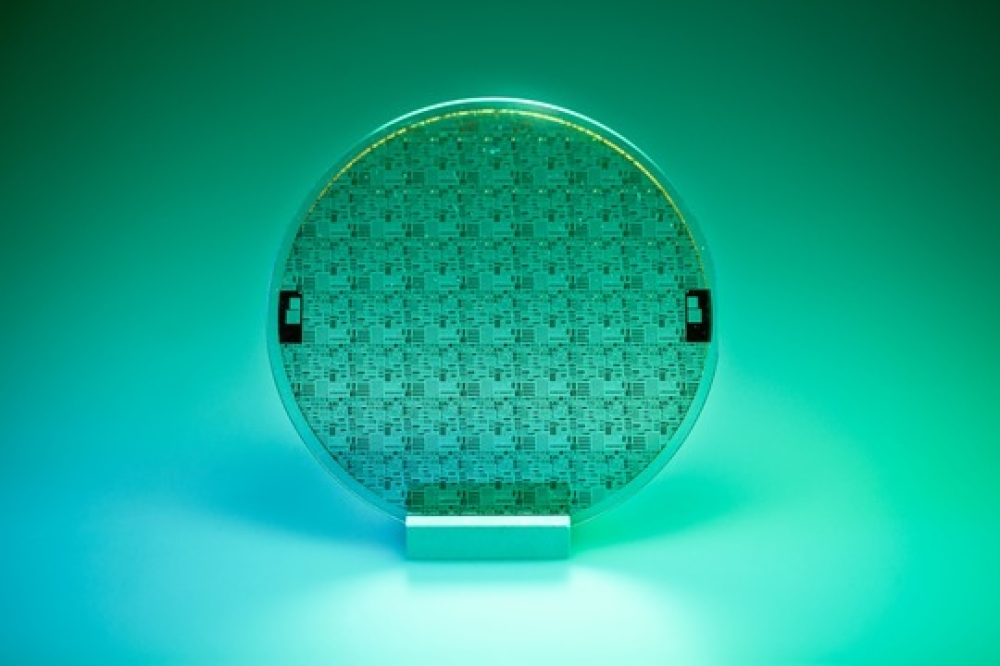

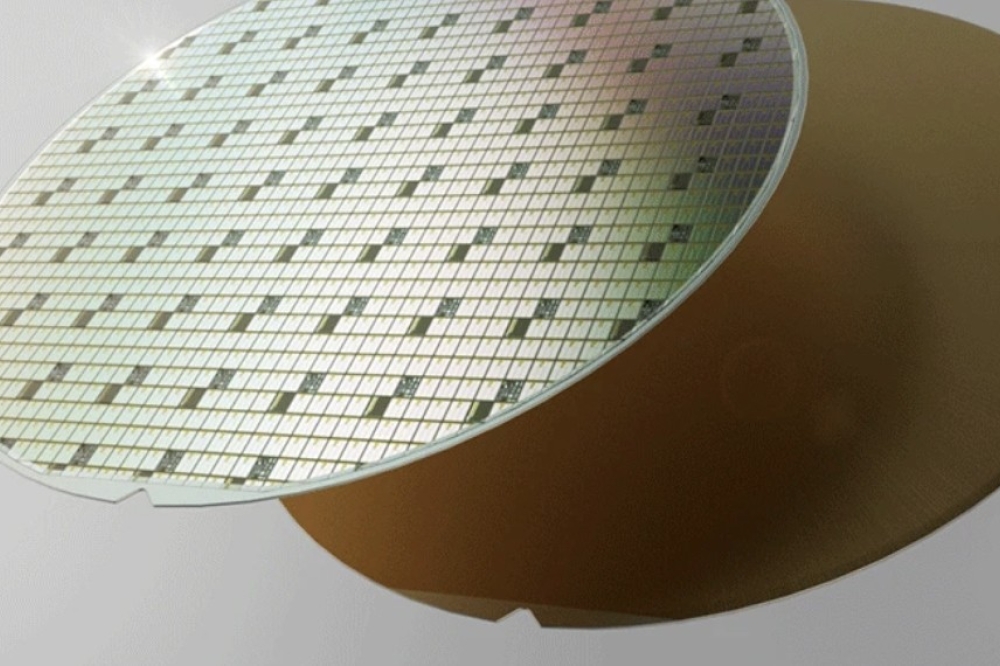

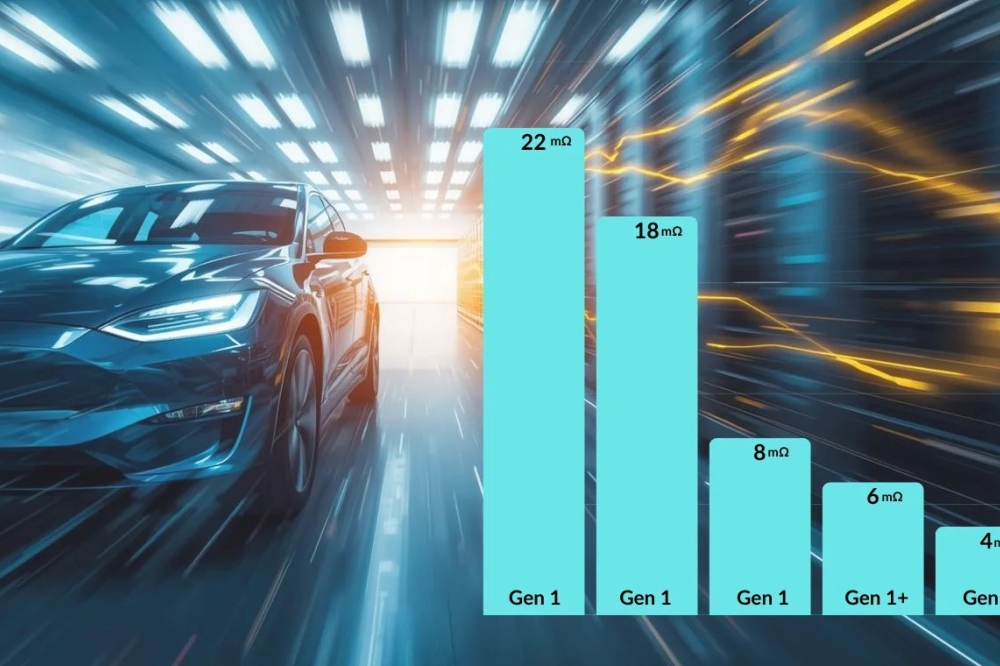

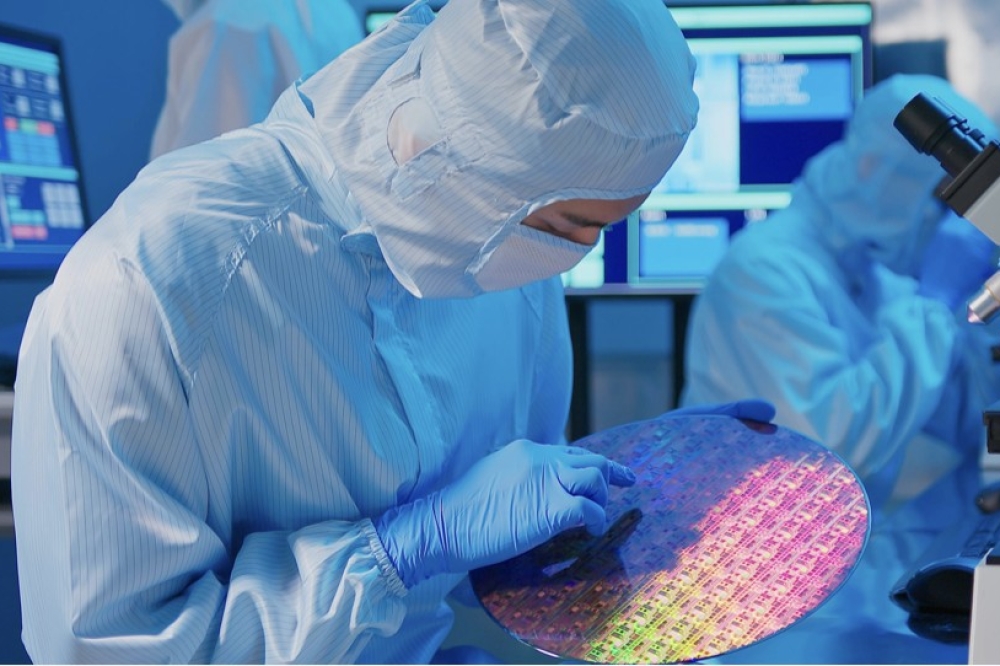

The core objective of the project is to rapidly develop an advanced multilevel traction inverter integrating GaN switches, and featuring adaptive gate drivers to improve switching controllability and further reduce energy losses. Hofer Powertrain says its has made significant strides in developing advanced multilevel power electronics using GaN chip technology over the last four years already, resulting in enhanced efficiency and power density compared to silicon-based systems.

The collaborative project with ETH Zurich builds on Hofer's experience making 800V GaN inverters to realise a new inverter solution, which aims to use a novel modulation scheme, operate at very high switching frequencies, and incorporate a wide array of additional pioneering features that the company has been working on in recent years.

The project will be supervised by Johann Biela from ETH Zurich, an expert in power electronics, and Lukasz Roslaniec, the division lead of power electronics at Hofer Powertrain, who brings extensive industry experience to the table and has been working on these technologies proactively.

Roslaniec said: "We eagerly anticipate the fruitful collaboration with ETH, renowned for its groundbreaking work in Power Electronics and Electric Drives. We are confident that our partnership will yield solutions that are not only technologically advanced and unparalleled but also financially accessible, thereby pushing the adoption of electric vehicles and environmental sustainability in the region and beyond."