Crushing MOSFETs one tipping point at a time

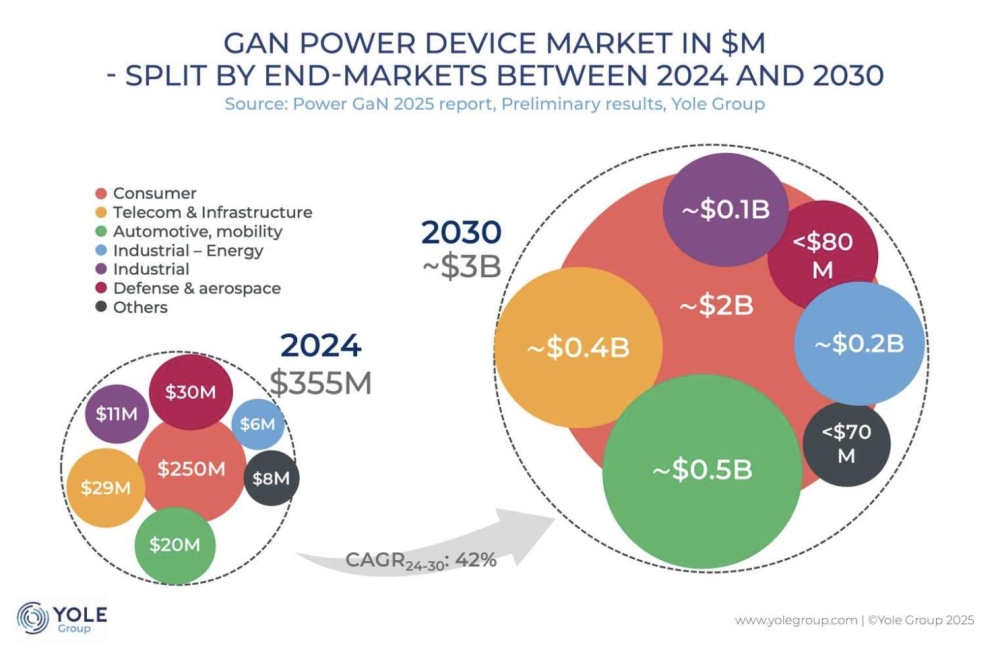

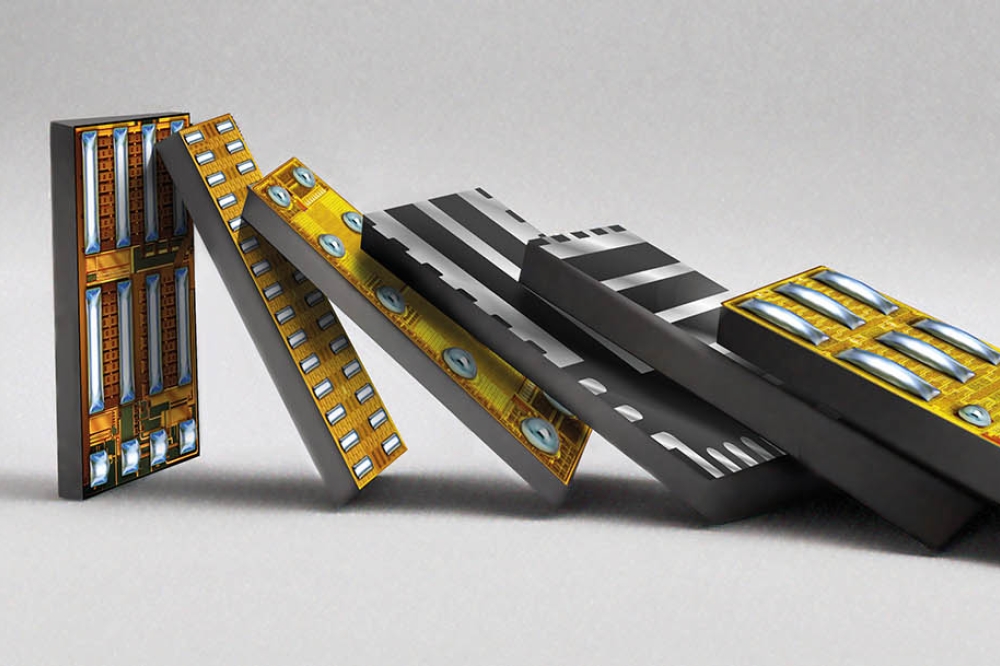

The growth of GaN is inevitable as it displaces the MOSFET in one application after another.

BY ALEX LIDOW FROM EFFICIENT POWER CONVERSION

GaN power transistors are at a tipping point. It’s a juncture where any small change or action leads to significant and often irreversible effects, and the future of these devices has reached a point of no return, where the dynamics of the situation shift dramatically.

This tipping point is following more than a decade of volume production of the GaN transistor. Since our company, Efficient Power Conversion (EPC), starting producing them in March 2010, they have repeatedly been touted as the replacement for the aging power MOSFET. Fourteen years on, the promise that GaN will crush silicon is now being realised.

To understand the changing rate of adoption of GaN, one can draw lessons from the 45-year-old power MOSFET. It’s a device I know intimately, having been one of its first developers, as well as an instrumental player in the launch of the first product in November 1978. Back then the bipolar transistor was the incumbent power transistor. Despite being ten times slower, it was much cheaper than the MOSFET.

MOSFETs eventually crushed bipolar transistors. This did not occur overnight, but one application at a time. The first tipping point came from desktop computers, with Apple and IBM turning to the MOSFET for their AC-DC power supplies. By adopting the superior transistor of the day, these tech giants could shrink their power supplies enough to fit inside desktop housings, a breakthrough that played a crucial role in widespread adoption of these computers.

Following this breakthrough, our MOSFETs continued to increase their deployment in high-performance applications while we focused on reducing costs and accelerating the learning curve as quickly as possible. Initially adoption took time, but jumps occurred whenever a new application ramped successfully. With each new tipping point for an application, the benefits to the business would extend beyond this individual triumph to trim the time and increase the likelihood of subsequent successes. Motor drives for high-speed plotters ramped in 1982. Anti-lock brakes ramped in 1985.

By 1988, thanks to higher volumes and significant capital investments, the manufacturing cost for the MOSFET had plummeted to below that of the bipolar transistor. Since then, the world never looked back. At that point in time the MOSFET had officially reached its tipping point. And that’s exactly where GaN stands today.

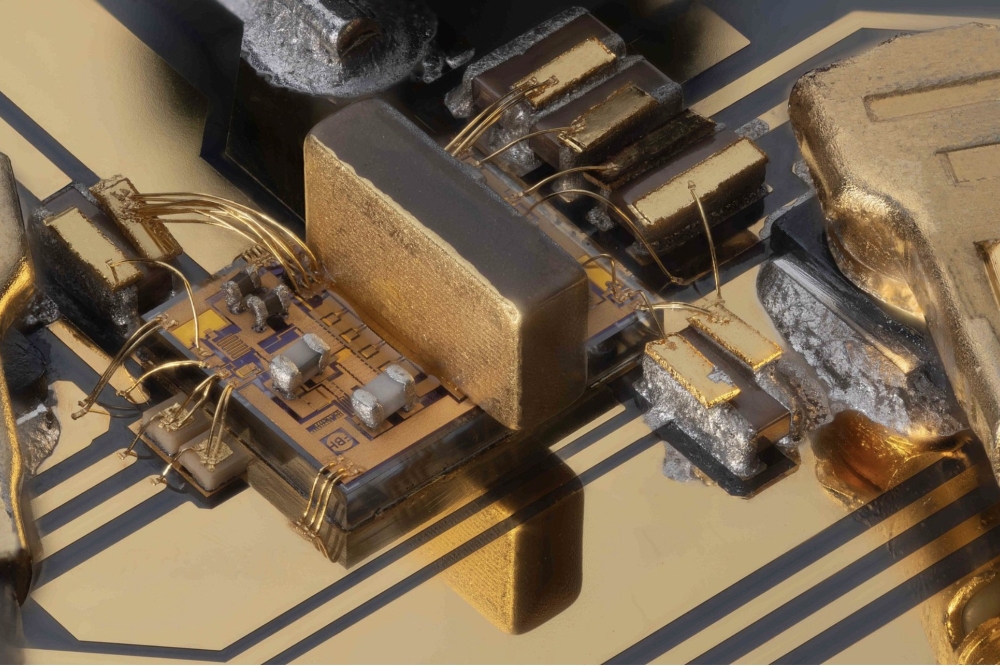

GaN has already been adopted in several disruptive technologies, to the point where MOSFETs are no longer even considered for new designs. Each novel application for GaN can be thought of as having crossed an individual tipping point. This roadmap for ever-expanding adoption includes lidar, fast chargers, satellite electronics, AI, DC-DC power supplies, and humanoid robots.

With nearly fifty years of experience to guide us, we can identify four key factors that have played a crucial role in ensuring that GaN reaches its tipping point and finally surpass the MOSFET. These four factors, which exist in addition to all the cost, performance, and reliability requirements, are as follows: the design community now clearly understands the large value derived from GaN; the targeted application is facing a changing landscape that leads to many open design windows; the adoption of GaN is being pursued by user community leaders, who are enjoying subsequent business success; and the existence of well-trained technical talent has emerged, which is capable of working with GaN and efficiently extracting its benefits.

For GaN technology, lidar provided the first application for crossing the tipping point. The simple reason behind this success is that GaN is capable of operating at far faster speeds than the MOSFET. Dave Hall, the visionary founder of Velodyne and the father of modern lidar, fully appreciated this benefit, realising that GaN technology enables a car sensor to see farther and with higher resolution than radar. Hall developed a spinning lidar system using EPC’s first-generation GaN transistors, sparking the birth of the autonomous car.

Considering lidar from the perspective of tipping point elements, one can conclude that: Hall had a clear understanding of the substantial value derived from GaN; lidar opened many new design windows as it became an essential sensor for autonomous vehicles; Velodyne had huge success, attracting lots of customers and competitors; and Hall, with some assistance from EPC’s engineers, knew how to extract the maximum performance from of these transistors.

The second application to reach a tipping point is the satellite power supply. As well as outperforming the MOSFETs, GaN is virtually immune from degradation caused by radiation in space. The key champion in helping to reach this particular tipping point is Dan Sable, CEO and founder of VPT. Today, just four years after initial deployment in this application, GaN transistors account for 30 percent of the satellite market for MOSFETs, and are on track to take the final 70 percent as legacy designs become obsolete or uneconomical.

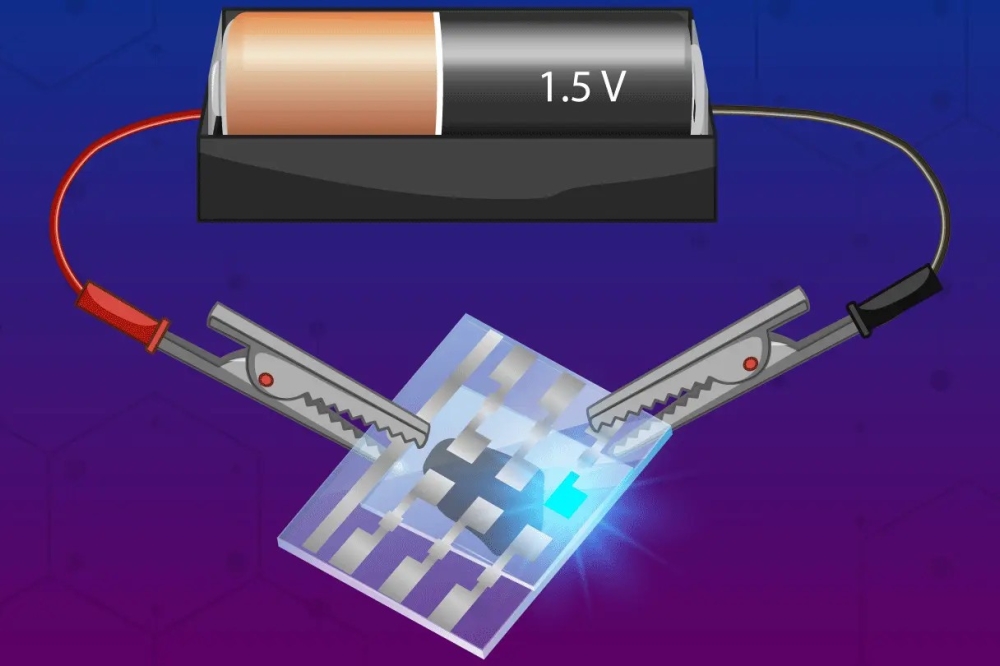

Providing the third tipping point for GaN is the fast charger. Here the standout is Gene Sheridan, CEO and co-founder of Navitas Semiconductor. Today, virtually all fast chargers use GaN, thanks to its capability to deliver high powers and recharge power-hungry cell phones, tablets and laptops in a fraction of the time that silicon-based chargers would take.

Following all this success, we are now standing on the precipice of one of the most significant tipping points in recent history: AI. Servers for AI, such as those made by Nvidia, have crossed a crucial threshold, with virtually all of them utilising GaN in the on-board 48 V – 12 V (or in some cases 5 V) DC-DC converters.

While the full impact of the AI revolution is only beginning to be fathomed, one inevitable outcome is related to the tipping point of humanoid robots. These robots, equipped with 40 or more high-performance motors, rely heavily on GaN technology for higher torque density, higher power efficiency, less noise, and a more compact design. It is a set of requirements that is making silicon obsolete and GaN indispensable.

Taking a step back from specific successes, one can see that the tipping points for GaN are occurring with greater speed and a higher frequency. As has been the case for the MOSFET, every new development is educating the user community on GaN’s unique value and accelerating its inevitable adoption in additional applications. And with each new positive experience and business success resulting from GaN, global implementation is rising, creating more and more design-window opportunities. Additional gains are the emergence of new GaN advocates within the user community, and new sources of capital. Over the last few years, thousands of trained design and manufacturing engineers have gone up the learning curve, and now know how to extract the additional efficiencies of GaN. Adding to these factors, GaN is proven to be more reliable than silicon, across a wide range of power levels, with a price that is comparable to the MOSFET. Due to all these compelling factors, it is inevitable that GaN’s adoption will only accelerate, consuming the $12 billion MOSFET market while creating new markets of its own. In sum, GaN’s tipping point is here.