Geely EVs using Rohm SiC MOSFETs

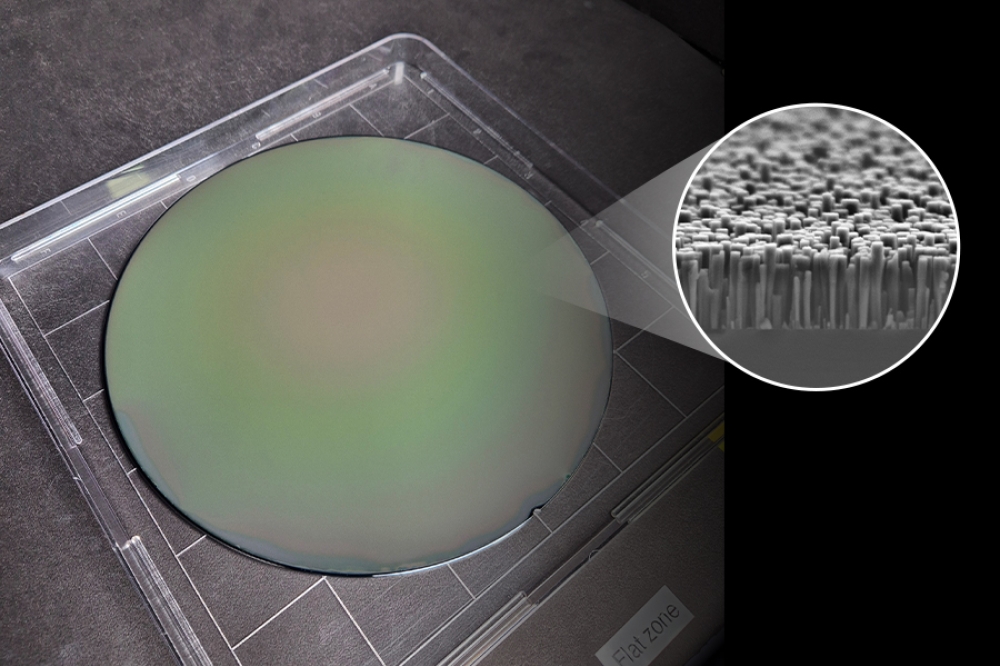

Rohm has announced the adoption of power modules equipped with 4th generation SiC MOSFET bare chips for the traction inverters in three models of ZEEKR EV brand from Zhejiang Geely Holding Group, a Chinese car maker. Since 2023, these power modules have been mass produced and shipped from HAIMOSIC Ltd. - a joint venture between Rohm and Zhenghai Group to Viridi E-Mobility Technology, a Tier 1 manufacturer under Geely.

Geely and Rohm have been collaborating since 2018, beginning with technical exchanges, then later forming a strategic partnership focused on SiC power devices in 2021. This led to the integration of Rohm’s SiC MOSFETs into the traction inverters of three models: the ZEEKR X, 009, and 001. In each of these EVs, Rohm’s power solutions centered on SiC MOSFETs play a key role in extending the cruising range and enhancing overall performance.

The ZEEKR X features a maximum output exceeding 300kW and cruising range of more than 400km. The 009 minivan features an intelligent cockpit and large 140kWh battery, achieving a maximum cruising range of 822km. The flagship model, 001, offers a maximum output of over 400kW from dual motors with a range of over 580km along with a four-wheel independent control system.