Breakthroughs in blue and green laser diodes

More powerful and efficient GaN-based lasers are aiding displays and simplifying copper processing.

BY RYOTARO KONISHI, YOJI NAGAO, TSUYOSHI HIRAO, KATSUHIRO KISHIMOTO, TERUYUKI MORITO, TOMONORI MORIZUMI, YOSHITAKA NAKATSU, TOMOYA YANAMOTO AND SHIN-ICHI NAGAHAMA FROM NICHIA CORPORATION

Recent improvements to GaN-based laser diodes (LDs) are positioning these sources as pivotal technologies in various applications. Opportunities have emerged in displays and laser processing, thanks to increases in the efficiency of this class of laser, along with a narrowing of its spectral width and the advent of exceptional reliability.

Within the display industry, the high efficiency and output power of GaN-based blue and green LDs are contributing to improved colour reproduction and brightness in digital cinema projectors, laser TVs, and large laser projectors. In addition, these emitters are supporting the development of high-performance RGB laser-light sources, enabling a wider colour gamut and enhanced visual experiences.

Meanwhile, in the industrial domain, high-output-power blue LDs are significantly enhancing laser processing capabilities, particularly for challenging materials like copper. These powerful sources are enabling high-precision and efficient metal welding, cutting, and processing, opening new fields in manufacturing and processing technology. They include opportunities in sectors such as the automotive industry.

Figure 1.Nichia’s history of the 455 nm blue LDs.

Technological advances in blue lasers

As is often the case with compound semiconductor technologies, improvements to the performance of GaN LDs have taken place over many years. Nichia, as the pioneer and leading producer of GaN LDs, has driven these advancements.

The development of blue LDs, pioneered by our company, began in earnest in the early 2000s, with the first successful demonstration in 2001. Back then, lasers delivered a modest optical output of just 5 mW. Thanks to rapid advancements, the first watt-class LDs were introduced in 2007. By 2022, we realised another impressive milestone in the history of the GaN LD, the first device surpassing a wall-plug efficiency of 50 percent.

Increases in the wall-plug efficiency and optical output of these blue LD chips have not come in the form of a handful of big jumps, but steady improvements over many years. This progress is attributed to both technological innovation and optimisation of the manufacturing processes (see Figure 1).

Our 455 nm blue LDs have a mere 2 nm spectral width, concentrating almost all their optical energy within this narrow range, which is approximately one-tenth of the spectral width of conventional LEDs. This capability to convert half of the electrical input power into laser light within a range of just 2 nm highlights the efficiency of our technology. However, this efficiency still lags behind the best GaAs-based LDs, indicating room for further improvement.

The manufacture of our LDs begins by loading a 2-inch c-plane freestanding GaN substrate into an MOCVD reactor and depositing an epitaxial stack consisting of n-type layers, and the active region, and finally p-type layers. Subsequent etching of the p-side of this epiwafer creates a ridge structure, to which we add n-type and p-type electrodes (see Figure 2). Production of the laser is completed with the addition of mirrors, created by cleaving the wafer and coating the bare facets with dielectric mirrors.

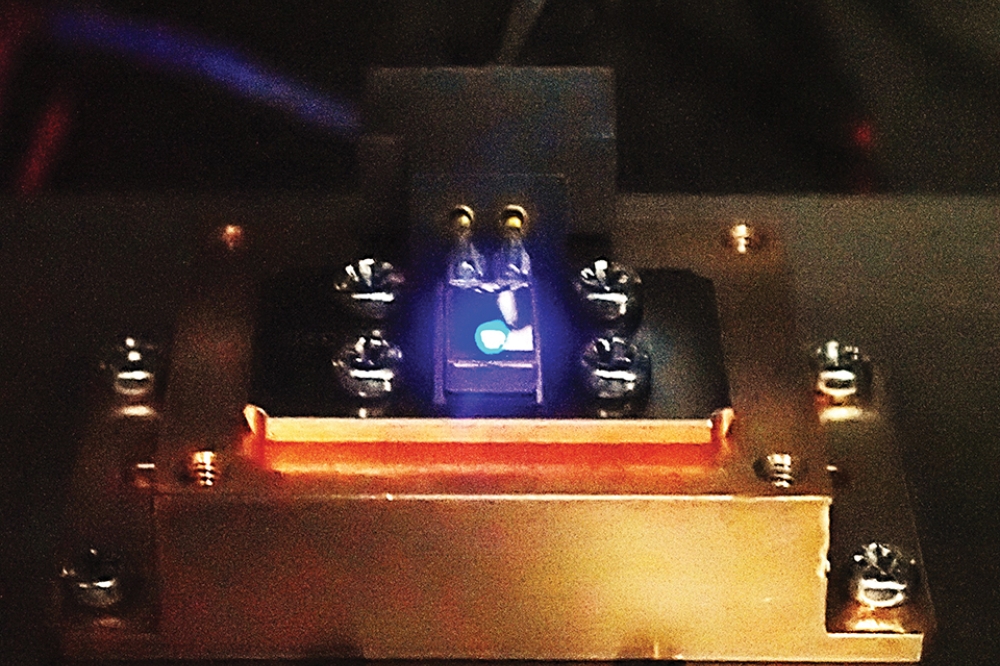

Figure 2. Nichia’s multimode laser diodes.

To minimise optical absorption losses, we meticulously design the optical confinement structure of our epitaxial stack. This careful consideration is crucial for ensuring that our LDs have a high efficiency and performance. In the final step of the laser manufacturing process, we employ a junction-down method to mount our chips into TO-Can packages. This approach trims thermal resistance and enables optimal heat dissipation.

Earlier this year, we announced a 455 nm blue laser with an optical output of 7.11 W and a wall-plug efficiency of 53.2 percent, under a drive current of 3.5 A (see Figure 3). These record-breaking figures have been realised through improvements in chip design that include reducing internal absorption losses, enhancing carrier injection efficiency, trimming operating voltage by reducing resistance, and decreasing thermal resistance by expanding the cavity length.

One of the standout characteristics of our blue lasers is their exceptional reliability. Based on a lifetime test lasting 5,000 hours at a rated current of 3.5 A, we estimate a lifetime that exceeds 30,000 hours (see Figure 4). Thanks to this reliability, our blue LDs are expected to last significantly longer than conventional lamp light sources, which typically require replacement after a few thousand hours.

To accommodate various output requirements, multiple blue LDs can be packaged together. This approach creates light sources with optical outputs ranging from 20 W to 100 W. Recently, there has been a global shift from lamps to solid-state light sources, and this trend is expected to continue. At the heart of this transformation are LDs, which are anticipated to become mainstream across all markets.

Figure 3. (a) Current-light (I-L) and current-voltage (I-V)

characteristics of blue LD under CW operation at 25 °C. (b)

Current-WPE(I-WPE) characteristics of blue LD under CW operation at

25 °C.

Gains for green lasers

Another recent triumph is the increase in the wall-plug efficiency of our 525 nm green LDs to just beyond 25 percent. Note that these lasers can fully cover the standards of digital cinema in the green region.

Key to our success is tackling the challenges related to piezoelectric polarisation, which reduces the overlap between electrons and holes and thus lowers the radiative efficiency. Our solution involves thinning the active layer. Although piezoelectric polarisation still occurs, a sufficiently thin active layer helps to mitigate the reduction in light emission.

We have observed and recorded the advantages of thinning the quantum wells within our green LDs. Our 525 nm device that benefits from a low threshold current produces an optical output of 1.97 W at a 25.2 percent wall-plug efficiency when driven at 1.9 A (see Figure 5). Additionally, we have begun in-house production of GaAs-based red LDs alongside the blue and green LDs reported here, enabling us to respond flexibly to customer demands and accelerate the development of RGB products.

Figure 4. Lifetime test results of blue LDs under an automatic current

control of 3.5 A CW operation at a case temperature of 70 °C. Operating

current is normalised by its initial value.

Processing with blue lasers

In addition to contributing to display brightness, blue LDs are playing a crucial role in laser processing. Since 2017, we have been developing lasers for copper processing, successfully commercialising ultra-high-power lasers that far exceed those used for displays.

As the mobility industry transitions from gasoline vehicles to electric vehicles (EVs), demand for copper processing is increasing. Copper plays a critical role in EV performance, due to its high conductivity, and this material is widely used in motors, batteries, and other key electrical components.

Traditionally, the processing of metals with lasers has involved the use of sources in the infra-red. But that’s not a great spectral domain for copper, which is a challenging material to process, due to its high thermal conductivity. Switching the wavelength from the infra-red to the blue is highly beneficial, with the energy-absorption efficiency in the blue more than ten times higher than that in the infra-red. Due to this, blue lasers enable more efficient energy transfer, making them very attractive candidates for processing copper, particularly in welding and cutting applications, where they are adept at meeting precision and speed requirements.

Thanks to these advantages, we expect our sources to lead to high-efficiency laser processing, stabilisation of the molten pool, and a reduction of spatter in copper welding. Realising a higher output power from blue LDs is essential for this purpose. Our developments have led to optical outputs exceeding 25 W for blue LDs used in processing applications, compared with about 7 W for display use.

To increase the optical output from a single chip, we have made significant changes to its structure. While display LDs have a cavity length of 1500 µm and a chip width of 150 μm, for processing we are promoting a far larger chip: it has a length and width of 4000 µm and 400 µm, respectively. These changes aim to reduce thermal resistance and accommodate higher currents.

Figure 5. (a) Current-light (I-L) and current-voltage (I-V)

characteristics of green LD under CW operation at 25 °C. (b) Current-WPE

(I-WPE) characteristics of green LD under CW operation at 25 °C.

Another change we have made is to switch from a conventional F9 package to a surface-mount device package, further reducing thermal resistance (see Figure 6). This refinement improves the thermal management capabilities of the LDs, enabling higher-current applications. While the rated current for display use is 3.5 A, for processing LDs are operating at 16.5 A, and delivering an optical output of 26.8 W at a wall-plug efficiency of 41.6 percent (see Figure 7).

Figure 6. (a) ф9 package. (b) Surface-mount device package.

We have demonstrated the reliability of our high-output blue LDs through rigorous testing. Undertaking lifetime tests at a rated current of 16.5 A, we have found that power degradation is less than 1 percent after 2,500 hours (see Figure 8). This result indicates that it’s possible to enjoy stable copper processing during prolonged operation, making our laser diodes a reliable choice for industrial applications.

Figure 7. (a) Current-light (I-L) and current-voltage (I-V)

characteristics of blue LD for processing under CW operation at 20 °C.

(b) Current-WPE (I-WPE) characteristics of blue LD for processing under

CW operation at 20 °C.

In conjunction with our advances in high-output blue LDs, we are developing blue direct diode laser modules for copper processing. These modules, incorporating multiple high-output blue LDs, produce optical outputs exceeding 800 W from a fibre with a core diameter of 110 µm. This 800 W model is currently in preparation for mass production, and is expected to significantly enhance laser processing capabilities across various industrial applications.

Figure 8. Lifetime test results of blue LDs for processing under an automatic current control of 16.5 A CW operation at a case temperature of 20 °C. Operating current is normalised by its initial value.

Looking ahead

Improvements in efficiency will be a valuable asset, not only for projector applications but also for various markets that include the industrial sector. The shift from traditional light sources to laser light sources is already underway, and is expected to accelerate further.

Looking ahead, our commitment to ongoing improvement and innovation in the field of laser technology remains steadfast. We anticipate that LDs will spur advances in various industries, and pave the way for new applications that leverage their unique characteristics.