Lumileds addresses microLED efficiency through EQE and directionality

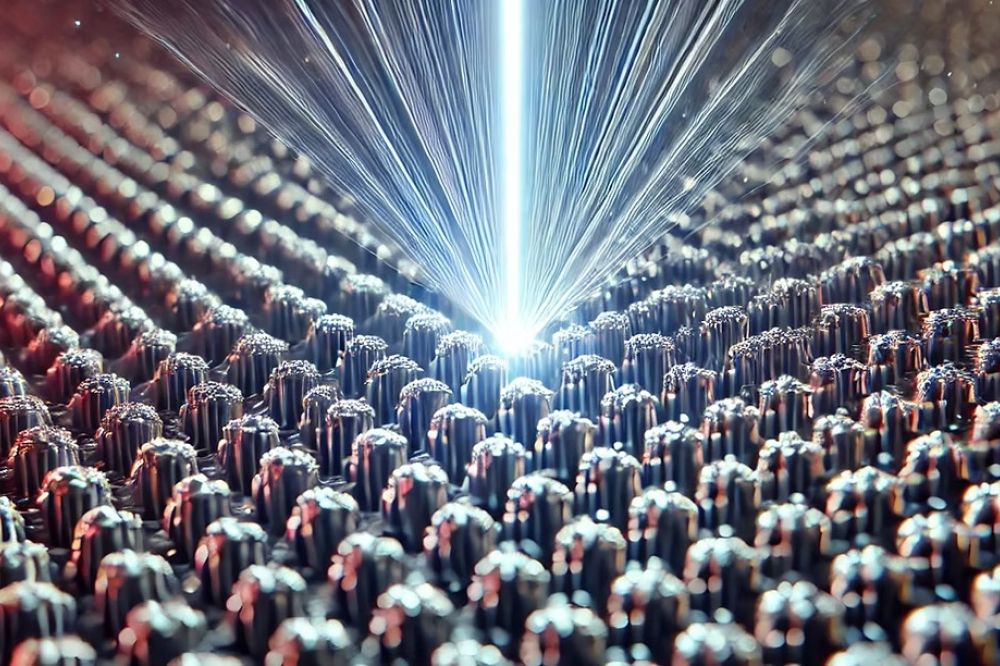

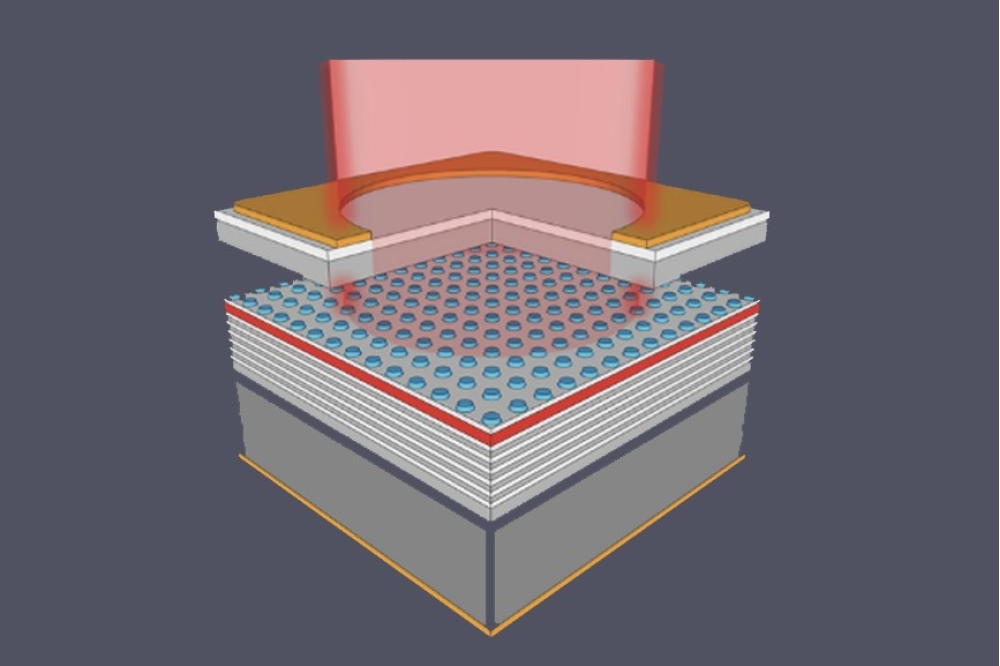

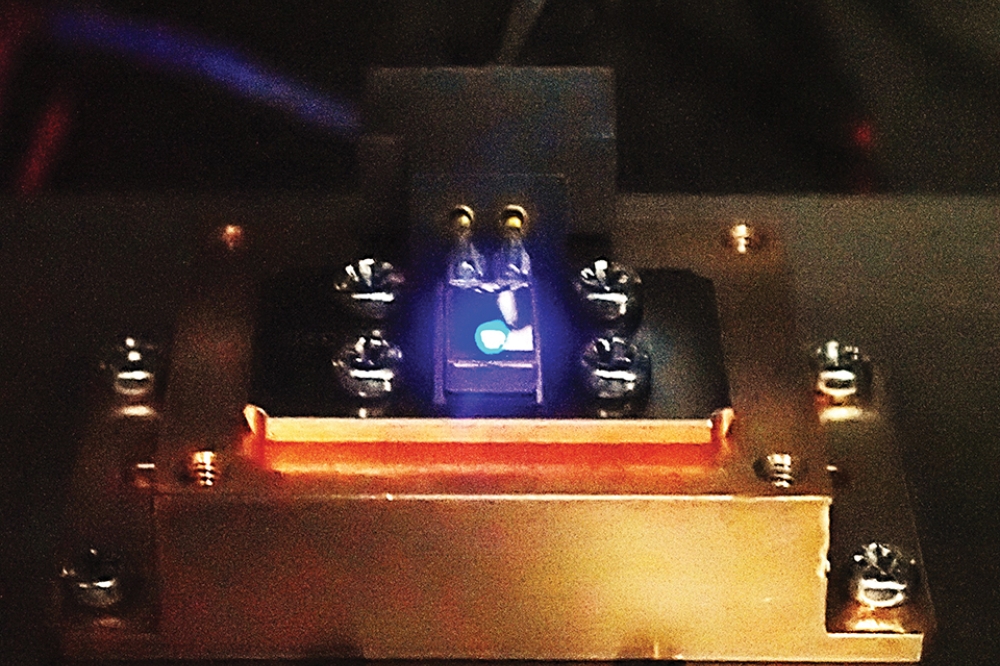

Lumileds’ R&D team realizes Lambertian distribution from microLEDs

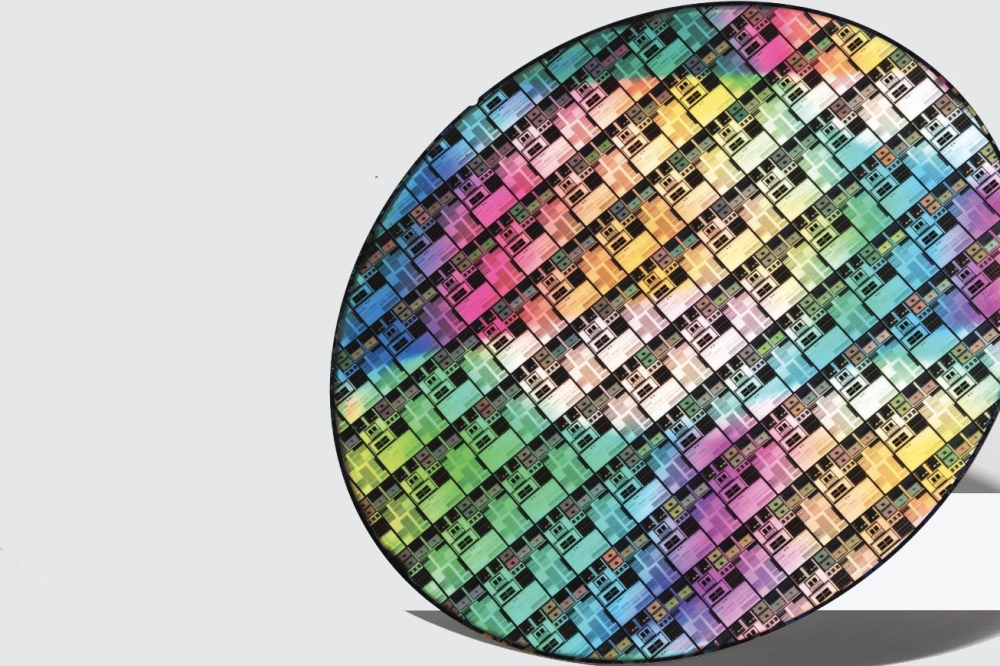

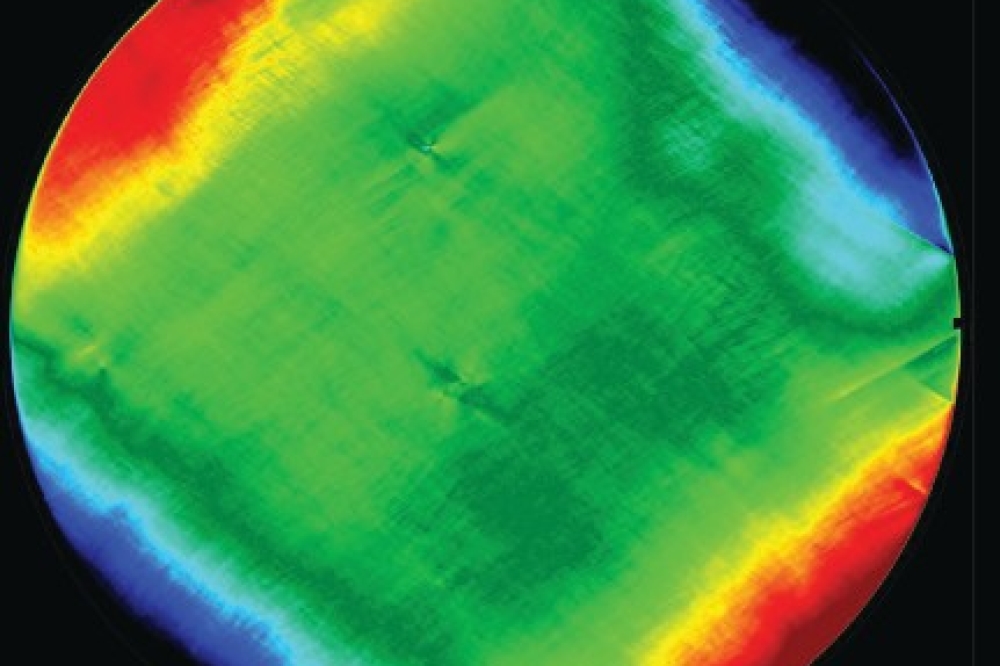

Lumileds has realized significant External Quantum Efficiency (EQE) performance for MicroLEDs in the past years. EQE, is the ratio between the energy contained in the light emitted from the LED and the energy in electrons injected into the semiconductor material. However, for microLEDs, and display applications in particular, EQE on its own is not a sufficient measure of performance. To properly assess the efficiency of a microLED, one must also be able to measure the directionality of the light. The directionality of light is critical for microLED displays, and for this reason, displays are often characterized by Radiant or Luminous Intensity, as seen from an angle.

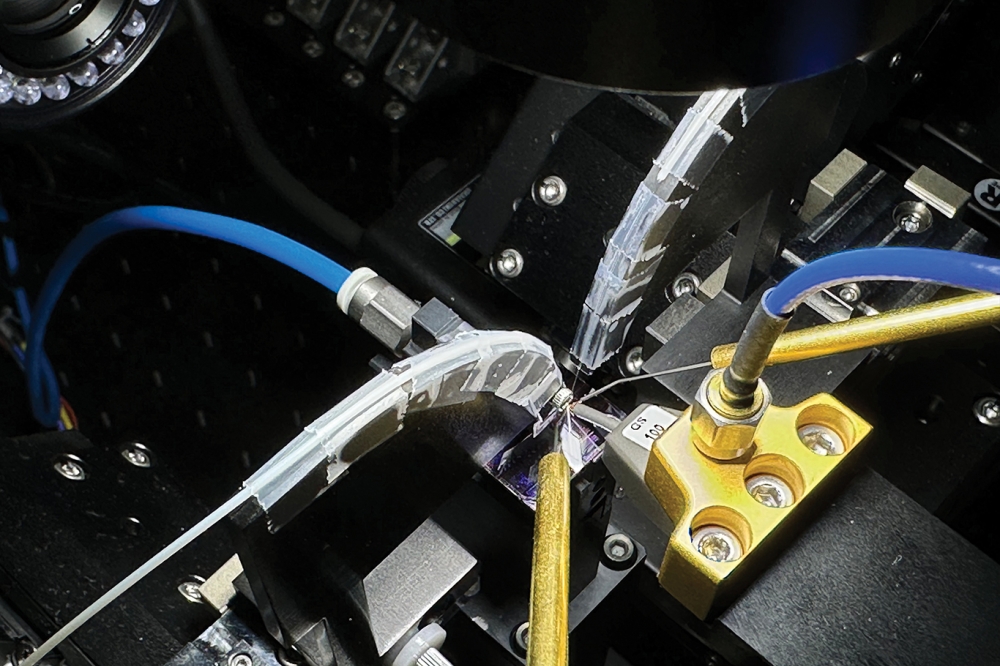

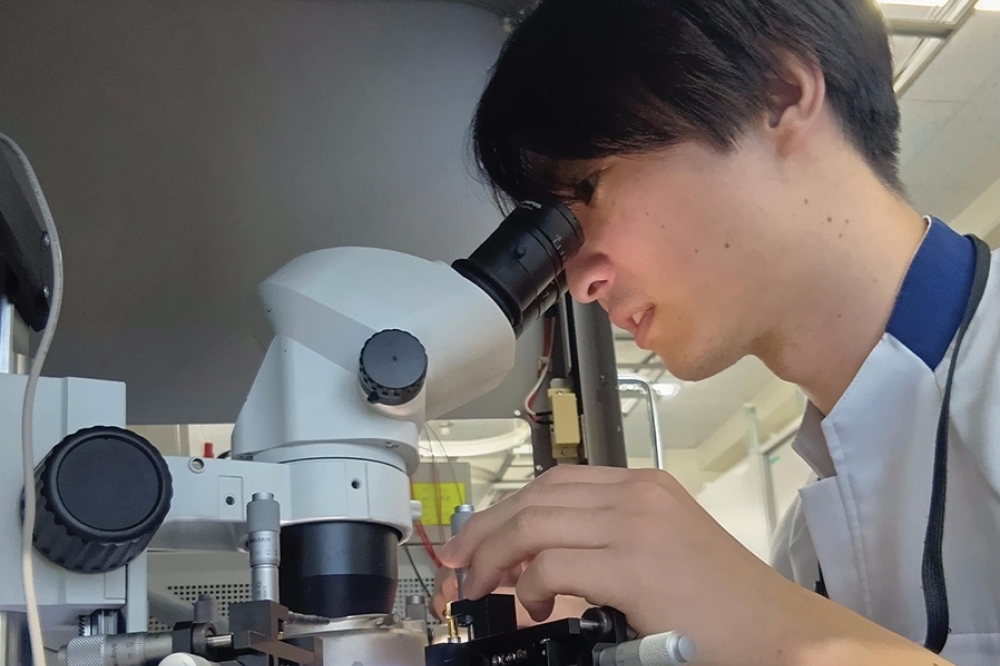

“Most LEDs emit the majority of light from their top surface. This is especially true for thin film LEDs. When we shrink the size of thin film LEDs to become microLEDs, the ‘side-emitting’ surfaces become a significantly greater portion of the overall light-emitting surfaces,” explained Brendan Moran, Lumileds’ Senior Director of MicroLED Development.

“The thickness of what we described as a thin film for a larger size LED now becomes substantial relative to the length and width of the microLED. This is a key reason why microLEDs emit a large portion of light from their sides, resulting in a wide viewing angle distribution and a reduction of intensity emitted from the top surface. For display applications, even high EQE microLEDs can have relatively low on-axis intensity,” said Moran.

The Lumileds R&D team has now developed microLEDs with a highly desirable light distribution that approximates Lambertian distribution. The team’s innovation results in brighter displays that consume less energy.

Brendan Moran will present on microLED advances and efficiencies at the PlayNitride MicroLED Technology Forum on September 3rd, 2024.