A holistic approach to growing with AI

Bizmuth MBE is advancing thin-film growth by drawing on the capabilities of the latest AI technology

It’s often said that the devil is in the detail. And that’s certainly the case when turning to AI to optimise the production of compound semiconductor devices.

While AI is grabbing headlines in today’s mainstream media for its transformative potential, it’s not a new technology. Its initial development dates back many decades, and includes the pioneering efforts of the brilliant British mathematician Alun Turing, who published a seminal paper in the 1950s.

In recent times AI has grabbed much attention in our industry as a tool for classifying defects and aiding epitaxy, and when it comes to the later, one should not assume the support provided by AI is fixed. It’s not: it’s evolving, with capabilities that are sure to grow over many years.

Although some of the AI advances within our industry may be hidden from view, as the downside of patenting IP is that it discloses ideas, it is well known that IVWorks has been promoting the use of AI for many years. Based in South Korea, this provider of GaN epiwafers has put thin-film AI on the map, drawing on this technology since at least 2019.

However, while deep learning was at the forefront of AI a few years ago, the technology has moved on. Now the new kid on the block is the large-language model, which allows AI to draw on all information that’s publicly available, including every journal paper, text book, and all material on the internet. Within this model is a multimodal feature, enabling AI to understand the make-up of images – this allows for comprehension of the reflection high-energy electron diffraction (RHEED) images provided by in-situ tools during MBE growth that are key to monitoring epitaxial processes.

IVWorks hinted that they will be working towards the introduction of these new AI technologies at their foundry. But they are by no means alone, with London-based start-up Bizmuth MBE striving to get there faster, with an AI toolkit that operates at the system level and will be available to all.

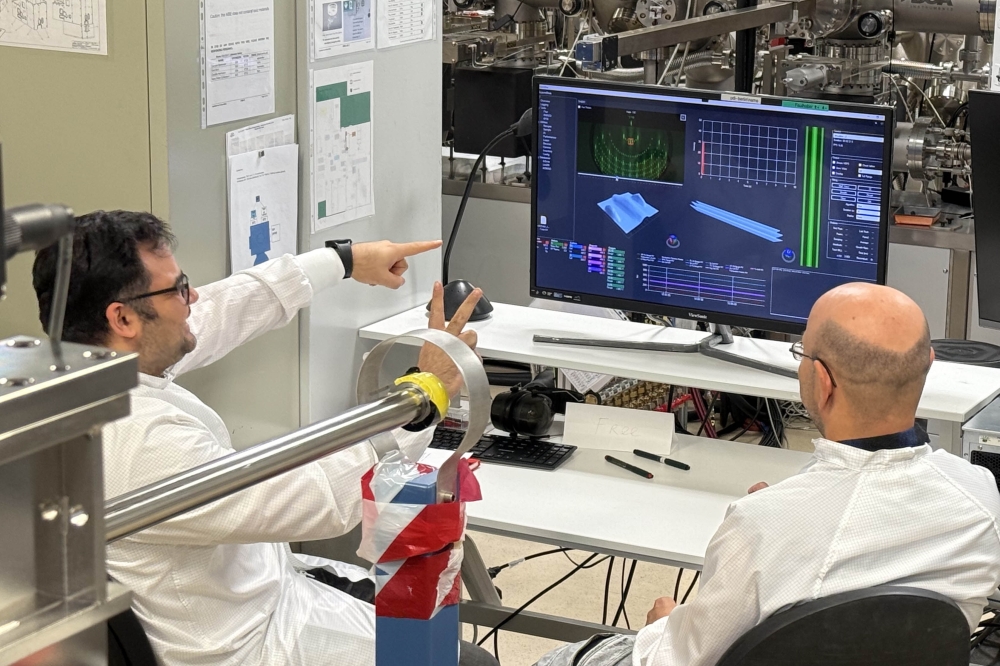

Founded just a year ago, Bizmuth has a tremendous track record in software-related innovation to support MBE, having established relationships with the University of Sheffield and HRL, and just started a ground-breaking project with the Paul Drude Institute, a world-renowned pioneer of MBE.

The duo behind Bizmuth are its CEO, the third-generation entrepreneur and environmental scientist Isabella Lorente, and CTO Faebian Bastiman, who has a PhD in MBE and passion for coding. This pair have previous experience in founding companies, having launched a firm producing a water purifier for the consumer market, and are now working together to offer the world an AI technology for thin-film growth that will ultimately operate at the system level, delivering what is essentially a lab operating system.

Bizmuth has not pursued external funding. “Everything that we have accumulated has been earned, not raised,” says Bastiman, explaining that revenue has been generated through sales of software and fees from delivering seminars covering many matters related to MBE.

One of the merits of this approach is that Bizmuth is making its own plans, rather than having to compromise to placate investors.

Bastiman sums up the company’s philosophy as this: “We want to walk before we run, and then we want to still be running for decades to come, building really ambitious tech, grounded in sustainable business sense.”

Bizmuth is developing an entire ecosystem in a very structured, logical manner, building on software produced by Bastiman over many years.

More than a decade ago he created a piece of software called Epic, designed to control MBE equipment.

“It was everything that I'd been missing from 2004 to 2012 as a grower,” explains Bastiman. “I wanted automation. I wanted automatic flux checks. I wanted to know the composition of what I was growing, etc. I wanted to know how much material is left in my cell.”

After offering all these features to others through Epic, Bastiman introduced a pair of software packages: Nexus, which is MBE control software that’s built on Epic; and a RHEED analysis software called Pulse.

“The reason why I made Pulse is that there was no other RHEED software that you could talk to,” says Bastiman, who explains that with this breakthrough, growth software can instruct RHEED software to undertake oscillation checks, thereby determining growth rates and automatically calibrating the MBE tool.

Following on from the introduction of an expanded software portfolio has been the MBE Academy. It’s a practical guide to this growth technology that’s emerged from a collection of blog posts from a dozen years or more. This source of knowledge, designed to make it easier for engineers to develop the expertise required for thin-film growth, addresses the omission of formal training for MBE.

Within the academy are interactive teaching tools, including one called Crystalmatic. “It's essentially just ball-and-stick models in 3D that you can spin around, go down to the unit cell, and come back up and build a structure for the common semiconductors,” says Bastiman. There’s also a RHEED simulator that allows users to input a crystal structure, calculate the reciprocal space equivalent, and see the resulting diffraction pattern.

A can-do attitude

Helping Bizmuth to get off the ground and generate an income is its willingness to serve its customers by providing solutions to whatever problem they have.

“We love a challenge,” says Bastiman, who is incredibly keen to modify software to address the needs of its users: “They didn't just buy a product. They bought a lifestyle. I want them to enjoy this lifestyle.”

The support provided by Bizmuth to researchers at the University of Sheffield has injected new life into legacy hardware, which is perfectly functional, but would not interface with software. According to Bastiman, by engaging with the services of Bizmuth, process engineers are avoiding ‘vendor lock-in’ and continuing to use their growth tool. “We allowed them to get several PhDs worth of results at a time where they would have been blocked and delayed by traditional methods.”

Bastiman says that when working with HRL, efforts have focused on delivering software that integrates with workflow and optimises proficiency.

This June, Bizmuth announced that it has just started an extremely ambitious project with PDI, which is renowned for its pioneering high-precision MBE, employed to produce a vast range of heterostructures.

Bastiman is tight-lipped when it comes to the details of the “multimodal mesh” technology being deployed, but he is willing to talk more freely about the aim of the project: It’s to determine the growth window for GaN on one MBE system, and then replicate this on two other systems.

“Finding the gallium nitride growth window is non-trivial,” argues Bastiman. “Anyone that's growing gallium nitride knows it's zero or one. You either get nucleation and material or you do not.”

The results of this project will have tremendous ramifications, claims Bastiman. “This is the proving ground for AI material science.” According to him, success will open the door to applying AI to all other growth technologies – including CVD, ALD, PVD – as well as characterisation equipment.

Bizmuth’s ultimate goal, which it is working towards with a step-by-step approach, is to employ AI as a lab operating system.

“We're going to expand to other meteorology tools, in-situ tools, and ex-situ characterisation tools, and then other deposition techniques,” says Bastiman, who explains that this effort will go hand-in-hand with an expansion of the MBE Academy to the Thin-film Academy, which will also offer expertise in MOCVD, PVD and ALD technologies.

“The overall goal is that every scientific lab in the world can have access to advanced AI tools and cutting-edge knowledge in their industry, with a low barrier to entry,” claims Bastiman. They are laudable goals, promising to transform our industry.