Transforming transfer technology for microLEDs

Q-Pixel addresses the biggest bottleneck to manufacturing microLED displays with an out-of-the-box transfer technology that combines a critical hike in yield with superior throughput.

BY RICHARD STEVENSON, EDITOR, CS MAGZINE

For around a decade or so, it feels like our industry has been on the cusp of a revolution in displays. But this breakthrough is yet to materialise. The only well-known display that’s based on the microLED is the Samsung MS1A, a 110-inch TV that retails for an eye-watering $150,000 – it’s so expensive that it’s not going to win many sales, even to those with piles of cash and a strong interest in home entertainment.

Many would argue that the biggest barrier to the widespread manufacture of displays based on the microLED is the transfer technology employed to move vast numbers of these miniature marvels from processed epiwafers to a backplane. While transferring microLEDs is not a pre-requisite for very small displays – they can be produced by bonding arrays of microLEDs formed on GaN-on-silicon epiwafers to a CMOS backplane that drives these emitters – a transfer process is non-negotiable for manufacturing displays for watches, smartphones, TVs and outdoor screens.

The big issue with conventional approaches to transferring microLEDs – such as the massively parallel techniques that involve picking-up vast numbers of these tiny emitters with an elastomeric stamp and placing them down on a backplane – is insufficient yield.

This view might raise a few eyebrows, as at first glance the yield figures realised with these traditional techniques look very impressive. But the reality is that they are not up to the task, argues J.C. Chen, CEO of Q-Pixel, a start-up with a yield-busting technology that’s looking to license its microLED-related technologies to chipmakers and those wishing to produce displays.

According to Chen, a commonly quoted yield figure for transfer technologies is 99.99 percent. “But in the microLED industry that’s a no-no,” claims Chen, pointing out that 24 million chips must be transferred to make an ultra-high-definition TV.

Expanding on this point, Chen explains that with a yield of ‘four-nines’, there are typically around 100 ‘dead’ pixels for every million transferred. “One hundred is very difficult to repair. But if you have ‘five-nines’ or ‘six-nines’, you have only one dead pixel.”

Part of the reason why ‘dead’ pixels are unacceptable is that we compare them with today’s OLED and LCD screens, and they have a very low level of defects.

“If you have 100 defects, you cannot really compete, no matter how good you are,” says Chen, who explains that it’s not possible to trade imperfections from dead pixels for the superior brightness and lower power consumption of displays based on microLEDs.

Breaking through this yield-related barrier is Q-Pixel’s novel transfer technology, known as Q-Transfer, that is claimed to have a yield of more than 99.9995 percent.

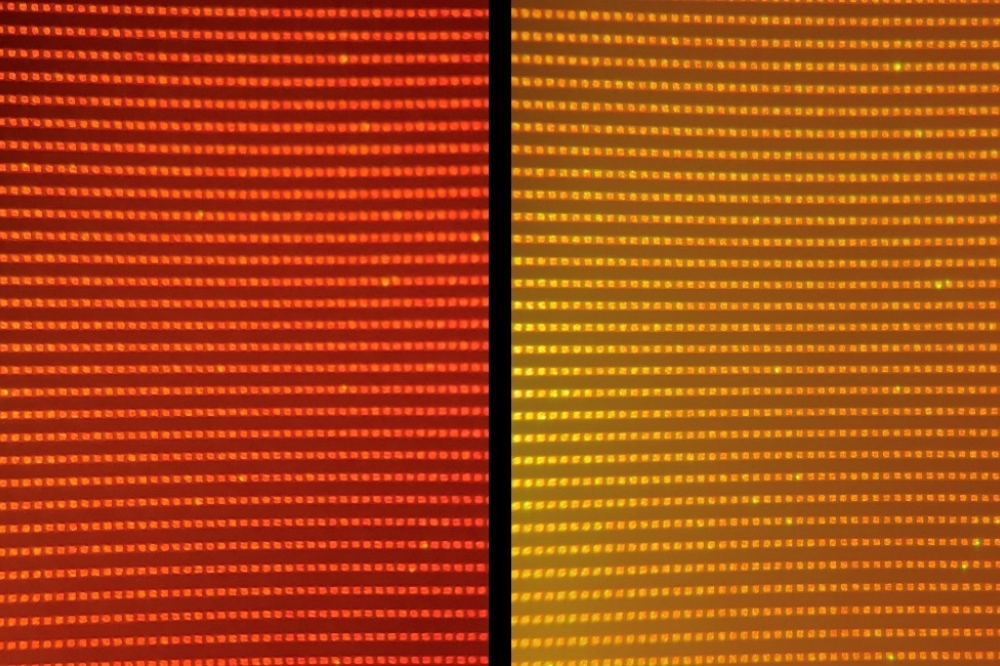

Chen and his co-workers have demonstrated the production capability of Q-Transfer by using this technology to make prototype colour displays with 10 µm pixels, that are spaced close enough together to provide a density of more than 500 pixels-per-inch. Q-Pixel stresses that as well as the phenomenal yield, this approach resulted in zero missing pixels.

Prototype panel demonstration of Q-Pixel’s proprietary transfer process, using 10 µm tuneable polychromatic microLEDs to produce a display with a pixel density of over 500 pixels per inch. There are no missing pixels, and yield is more than 99.9995 percent.

For understandable reasons, Chen is tight-lipped when it comes to discussing the details of the Q-Transfer technology, which is credited to ‘out-of-the-box’ thinking. But he says that Q-Transfer is compatible with most transfer technologies, without much modification.

The origins of Q-Transfer can be traced back to Covid times, which hampered much company activity, but allowed the team to mull over challenging issues and come up with novel ideas.

Since then, they have been developing a new approach to microLED transfer. Efforts began with small displays, which gave encouraging results. However, bigger displays are needed to convince the display industry that Q-Transfer can be a game-changer. “We need at least a watch-size display. If you have just a 1 centimetre by 1 centimetre, it's probably too small,” argues Chen.

Now Q-Pixel is demonstrating that its transfer technology is capable of producing displays for small watches. “That means the technology has become available to industry,” says Chen, who explains that this involves licensing Q-Transfer, and working with Q-Pixel on technology transfer.

Those interested in pursuing this will be keen to discuss throughput, as this plays a key role in determining the cost of manufacture. Those enquiring on this front will not be disappointed, according to Chen, as when Q-Transfer is applied to existing transfer approaches, the speed is similar, if not better.

Completing the puzzle

Chen views Q-Transfer as the last piece in the puzzle, when it comes to overcoming challenges to ensure an economically viable approach to producing microLED displays.

The company’s other key technology is it’s colour-tuneable GaN-based microLEDs. With this elegant device, emission wavelength is determined by driving conditions.

For all forms of GaN-based LED, there are concerns related to the efficiency in the red. Reaching this spectral domain demands an increase in the indium content in the quantum wells, a move that increases strain, leading to declines in crystal quality and emission efficiency.

Chen believes that for some applications, such as those that are indoors, the efficiency of Q-Pixel’s colour-tuneable microLEDs is sufficient. But for outdoor applications, it’s not so clear, due to a lack of data. “Honestly, we are not up to that point yet.”

What is beyond question is that microLEDs are incredibly compelling candidates for deployment in outdoor displays. Unlike those based of OLEDs and LCDs, they are not impaired by exposure to UV light, and they do not burn out.

Having demonstrated the key technologies to kick-start mass production of microLED displays, the next goal for Q-Pixel is to start working with companies that have invested in equipment to manufacture this class of display.

Such a partnership would be based on licensing technology from Q-Pixel. “We are basically an IP company. We're just doing the R&D and some demonstration,” says Chen.

He believes that such ventures could allow the microLED industry to take off.

“The whole industry is not moving fast enough,” laments Chen. “But I think that we can make it happen faster. That's our goal.”