Marktech introduces transfer-moulded packages

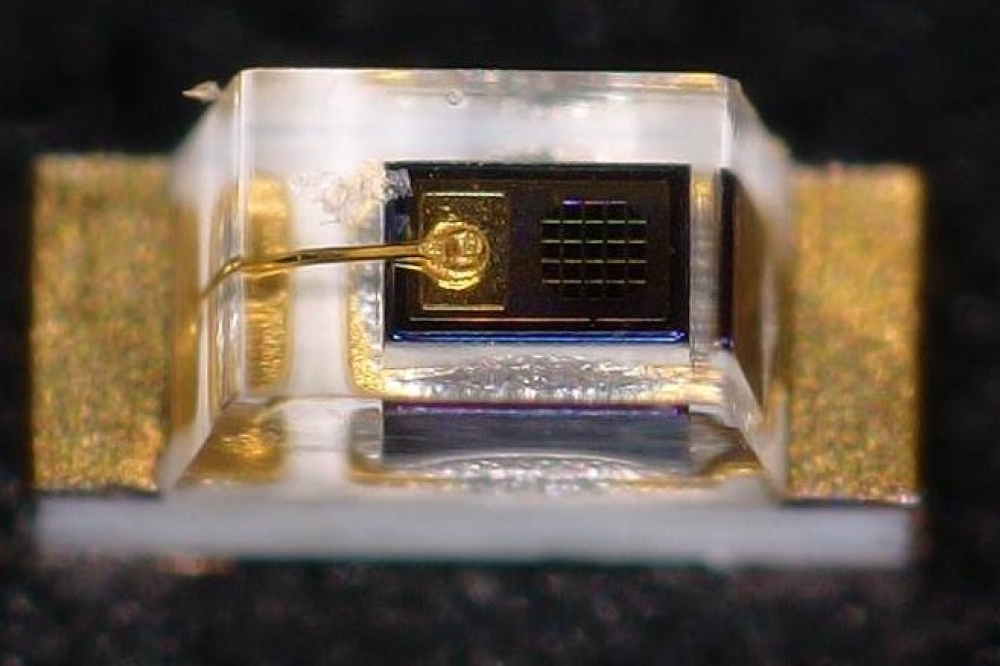

Marktech Optoelectronics and manufacturing partner Optrans are introducing new transfer-moulded photodiode and LED packaging capabilities, currently under development and scheduled for first customer availability in Q2 2026.

These next-generation photonics packages, which are suitable for emission and detection from 355 nm to 2300 nm, are said to offer improved reliability, optical beam control, enhanced environmental robustness, and reduced stray-light interference while supporting both conventional LED emitters and advanced point-source RCLED and QWLED architectures.

Transfer moulding forms a precision optical and mechanical structure directly over the die, encapsulating the LED or detector in a controlled moulding process that produces exceptional part-to-part uniformity, tighter beam profiles, stronger wire-bond protection, and improved long-term reliability under temperature and humidity stress.

According to Markteck, this approach offers significant advantages over traditional packaging methods—such as glob-top epoxy, liquid potting, COB silicone domes, and discrete lens cap assemblies—making it especially well-suited for industrial, medical, instrumentation, aerospace, and automotive applications that require repeatable performance, a small footprint for dense packing, and robust handling.

“Transfer moulding gives us exceptional control over optical geometry, reliability, and manufacturing scalability,” said Vince Forte, CTO at Optrans Corporation. “This is especially important for point-source LEDs where beam shape and emitter alignment directly impact system performance.”

Improved Optical Performance

Transfer-moulded packages allow for integrated primary optics, enabling tightly controlled lens profiles for beam shaping, collimation, and fibre- or aperture-coupling. This is particularly valuable for RCLED and QWLED point-source emitters, where sub-millimetre optical alignment is required for measurement, medical, aiming, and sensing applications.

The moulding process also provides excellent control over emitter-to-lens alignment, ensuring that the optical axis is precisely maintained from unit to unit—critical for applications requiring tight beam symmetry or long-distance projection. Transfer-moulded materials can be engineered for high UV, visible, or IR transmission, enabling improved radiant flux output and enhanced optical efficiency.

In addition, the package structure reduces internal reflections and minimises angular variation, resulting in more uniform and predictable emission profiles. Phosphor additives can also be incorporated directly into the moulding compound to convert or broaden the LED’s native emission spectrum, enabling tailored spectral outputs—such as multi-band, white-light, or application-specific wavelengths—without the need for external filters or secondary optics.

Mechanical stability is also enhanced, as the moulded compound encapsulates and protects the LED die, improving vibration resistance and long-term reliability in harsh environments. Wire bonds in conventional, non-encapsulated packages can fail by lift-off (wire debonding) or wire fracture due to mechanical stress from vibration, impacts, and thermal cycling.

A monolithic moulded package structure protects the die and wire bonds from shock, vibration, thermomechanical fatigue, and water ingress, resulting in enhanced durability and more consistent performance across temperature and mechanical extremes. This makes optoelectronic transfer moulded packaging technology an ideal choice for automotive, industrial, aircraft, and defense-grade requirements.

Transfer-moulded SMD optoelectronic packages offer a smaller footprint than many conventional SMD LED and photodiode package styles because the optical and mechanical structures—such as lenses, light shields, and housings—are formed directly in the moulded body rather than added as separate plastic components.

Engineering prototypes are planned for release in early 2026, with full production availability beginning in Q2 2026.