Polymatech: Propelling Indian optoelectronics

The launch of powerful UV LEDs for industrial curing helps to strengthen the emerging compound semiconductor industry in India.

Decade after decade, our industry goes from strength to strength. This is evident in growing revenues that are now totalling many tens of billions of dollars per annum, and the expanding reach of our devices – they are now powering EVs, charging mobiles and illuminating our world in numerous ways, to name but a few applications.

As well as increases in sales and applications, our growth is highlighted by the range of locations producing these chips. Back in the twentieth century, makers of compound semiconductor devices were found predominantly in North America, Europe, Japan and South Korea. But in more recent times you can add Taiwan and China to that list, and now India.

Entry of the latter is gathering pace, spurred on by a desire by the Indian government to make in India for India – that’s an ambition that goes back well before the introduction of tariffs by Washington. Success is already underway, evident through: SiCSem, building India’s first fab for manufacturing SiC chips; Navitas, providing a catalyst for the country to establish a GaN supply chain; and the efforts of Indian-based optoelectronics firm Polymatech Electronics, which has just expanded its portfolio of LED products. Its latest addition is a ‘world-class’ UV LED for curing applications, promoted at the recent Consumer Electronics Show (CES) in Las Vegas.

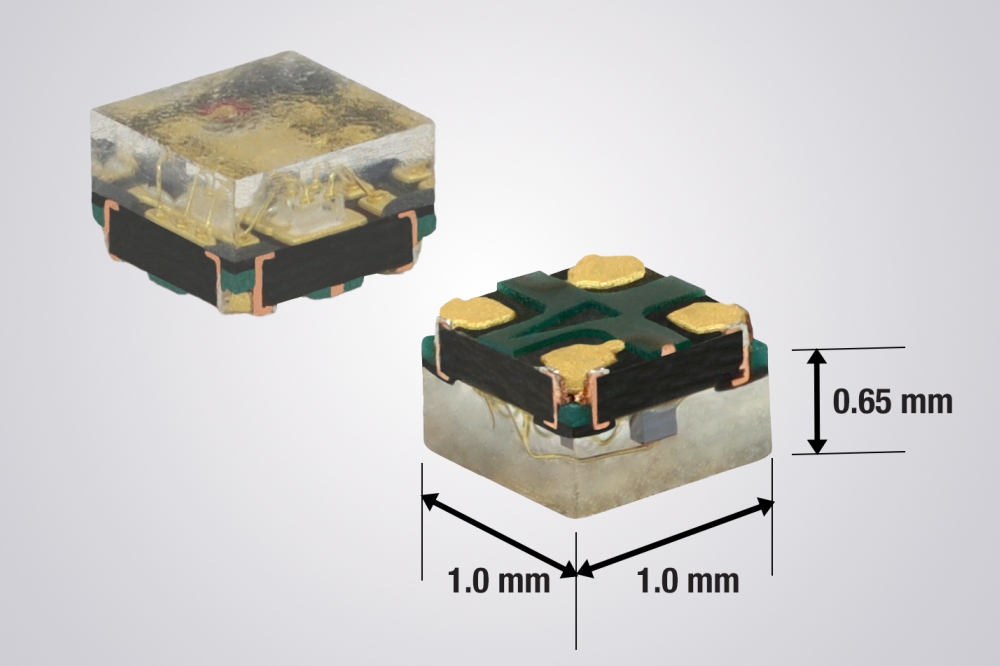

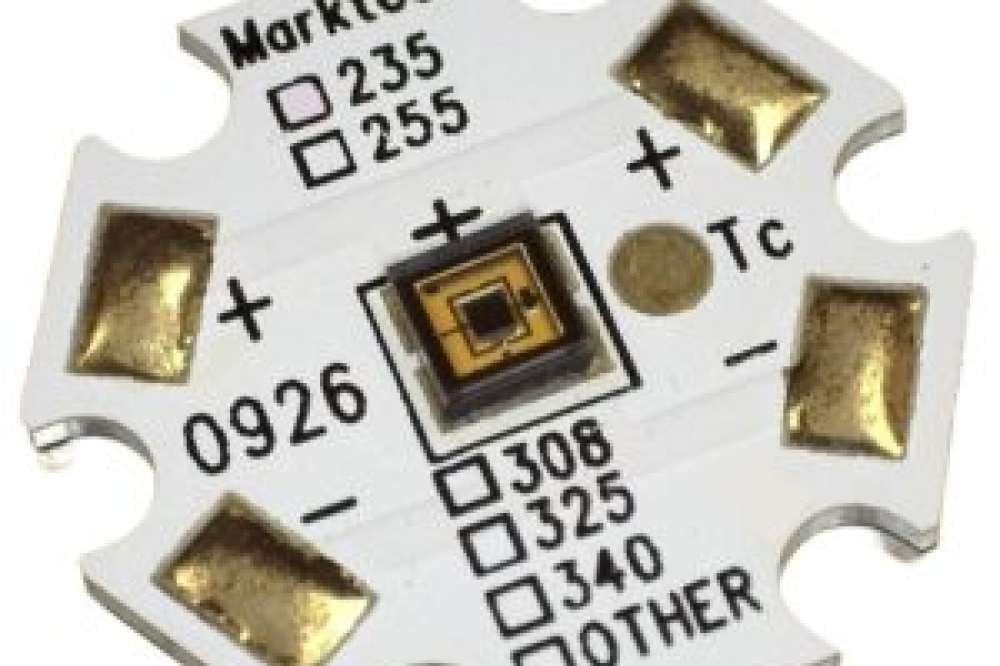

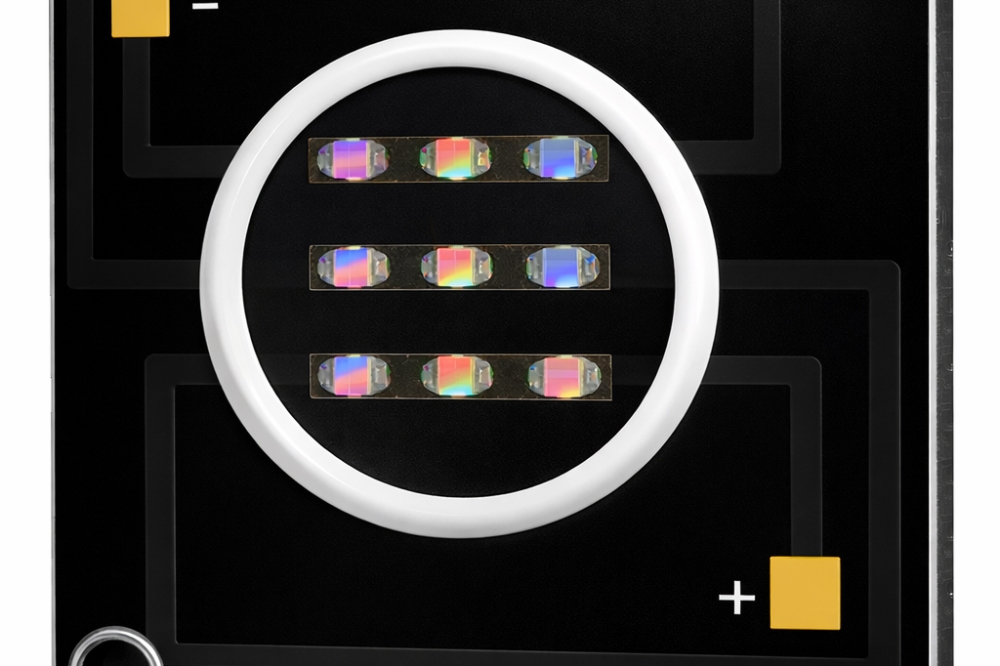

This UVA LED, emitting at around 400 nm, is said to deliver an industry-leading photon flux density that ensures sub-one-second curing.

Discussing this product with Compound Semiconductor, CEO and Managing Director of Polymatech, Eswara Rao Nandam, says that his company’s UV-LED platform can compete globally on three primary metrics: “One is electrical efficiency, second is operating lifetime, and third is optical power density.”

For the latter, viewed by Nandam as actually the most important, the CW optical power density for the UVA LED is around 150 W cm-2. As the chip size is typically a few millimetres squared, output is several watts.

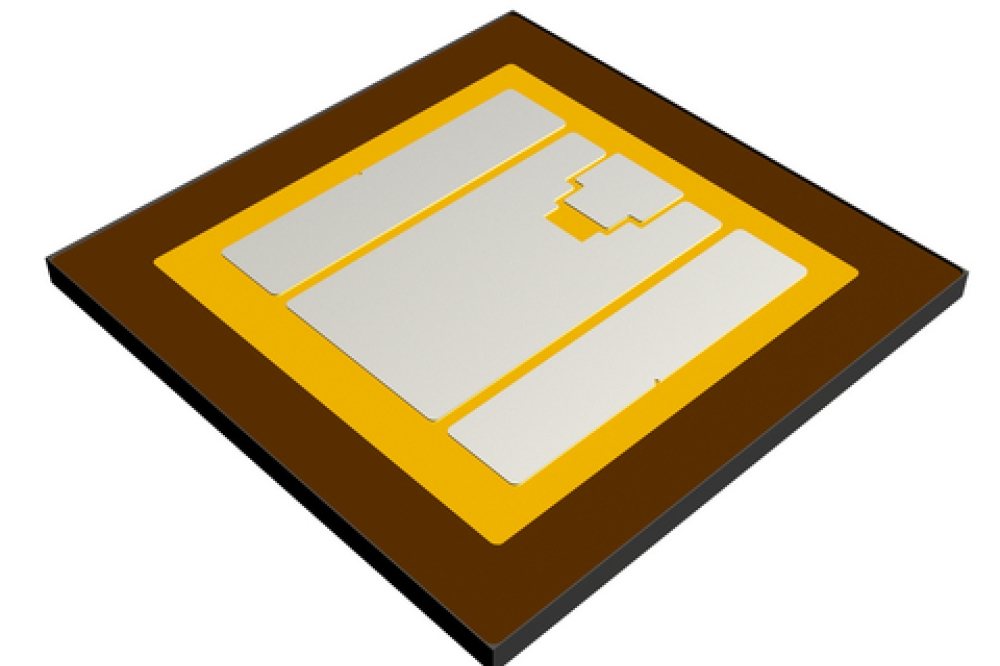

Polymatech’s UVA LEDs feature a chip-on-board architecture, selected for its superior thermal dissipation that stems from the aluminium substrates. Additional benefits of this particular design are uniform optical emission, an absence of interconnect losses, and a very high packaging density.

External quantum efficiency is 11.5 percent, notably higher than that for its siblings emitting in the UVC – they have values of 2-2.5 percent.

For the LEDs emitting at around 400 nm, lifetime is beyond 50,000 hours, based on defined operating conditions. This figure, defined by the time it takes for output to fall to 70 percent of its initial value, has been determined with the commonly adopted approach within industry that involves accelerated performance tests conducted at an elevated temperature and current.

According to Nandam, commercial opportunities for LEDs emitting in the UVA go well beyond what many imagine. As well as being employed for the curing of printing and packaging, these LEDs can provide a source for UV-cured coatings and finishes of automotive parts. There are also opportunities for very fast curing, found in electronics assembly, semiconductor assembly and 3D printing. Taken together, these applications create a global market for UV curing that’s already worth many billions of dollars, and is growing fast. “I will not say [the market is] expanding, I will say it is exploding,” enthuses Nandam.

CEO and Managing Director of Polymatech, Eswara Rao Nandam, previously worked for Nichia and holds a PhD from the University of California, Berkley.

A family business

After graduating with an electrical and electronics degree from the Birla Institute of Technology and Science in Pilani and gaining a doctorate in Electrical Engineering & Computer Sciences (EECS) from the University of California, Berkley, Nandam held positions in the compound semiconductor sector for several decades. During that time he has worked for various companies, including Nokia.

A key juncture came in 2011, when the tsunami in Fukushima sparked substantial losses for Japanese company Polymatech Electronics, a supplier of keypads for mobiles to the likes of Nokia, Ericsson, Sony and Motorola. Following that colossal and devastating tidal wave, Polymatech struggled for profitability for several years, ending up in arbitration. In 2018, the Nandam family purchased the company, revitalised it, and today its two key leaders are Eswara Rao Nandam and his son.

Under the leadership of this duo, Polymatech is expanding, in terms of its capacity, manufacturing sites, and where it plays within supply chains.

Initially starting with the packaging of chips for the automotive industry, Polymatech has expanded in many directions, drawing on sites it owns all over the world. There’s a factory in Grenoble, France, that produces sapphire ingots and wafers; a site in the US that makes semiconductor testing and failure-analysis equipment; and there are advanced packaging facilities in India and Singapore. And recently Polymatech has purchased a company in Estonia that produces printed circuit boards.

This expansion is helping reposition Polymatech from a packaging company to one that makes products. Within the optoelectronics domain, as well as UVA LEDs that have just been announced, there are products emitting in the near infrared that help to diagnose issues beneath the skin, and those in the UVC for water purification

In India, for India

In addition to overseas expansion, Polymatech is investing in its capabilities at home.

The key facility is at Oragadam, near Chennai. Here there’s advanced semiconductor packaging, R&D, ingot growth, wafer slicing, 3D printing and rapid prototyping.

“We make everything here, and we give it to other places in Singapore, or in the USA, or in Estonia, et cetera,” says Nandam, who adds that they are seeking permission from government for more land for this key site.

The two additional sites in India are located in Nava Raipur, which is home to a Polymatech industrial park with facilities for ingot growth, wafer manufacturing, epitaxy, packaging, and product assembly; and Bannihalli, Krishnagiri, a site currently under construction that will be dedicated to manufacturing products for the Domestic Tariff Area (DTA).

All these efforts are helping to equip India with what Nandam views as “real manufacturing”, rather than assembly services for other companies.

“We, Polymatech, are proudly building compound semiconductor expertise and developing skilled-engineer talent, anchoring India's high-value global chains.”

This lofty goal is pursued while maintaining efforts overseas, an approach that makes strategic sense.

“Singapore serves as a global customer interface,” says Nandam, describing this facility as a bridge between Indian manufacturing and international markets.

Nandam believes that Polymatech started 2026 strongly, with attendance at CES generating enquiries related to system adoption that could be worth billions of dollars.

Goals for the rest of the year include stabilising the plant in Singapore, expanding the facility in Estonia, scaling the output power of its LEDs and driving their adoption. And in addition, Nandam has another aim, which promises to leave a legacy: “I wish to establish India as a credible source of advanced semiconductor technology.”

Polymatech’s key facility at Oragadam is used for advanced semiconductor packaging, R&D, ingot growth, wafer slicing, 3D printing and rapid prototyping.