Thermally Stable Ag Mirror for Flip-Chip LEDs

WHU team enhances flip-chip LEDs performance by improving thermal stability of Ag mirror under high-temperature annealing

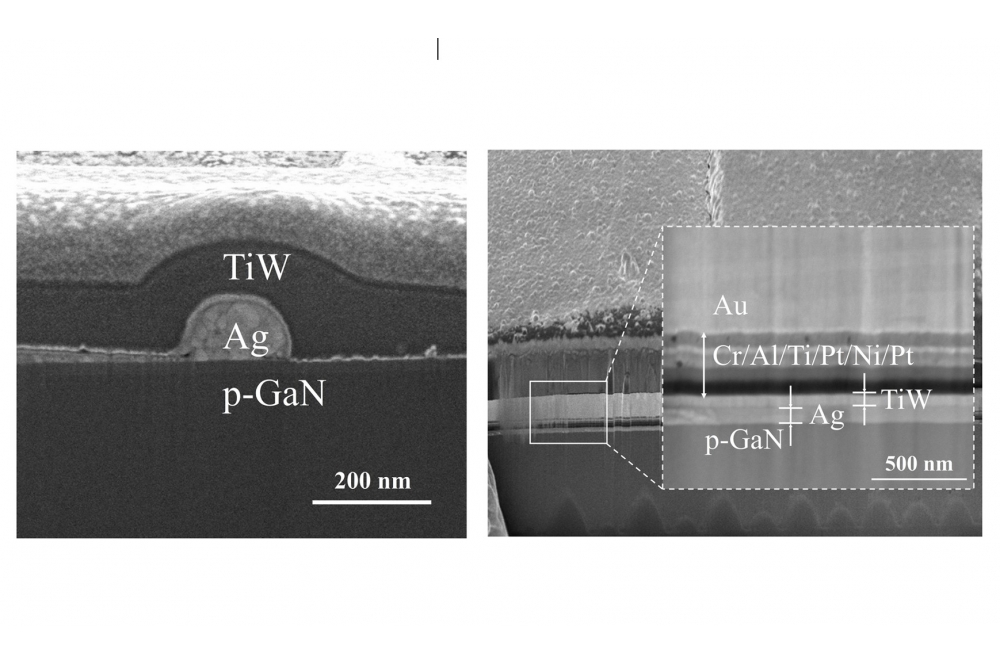

Researchers from Wuhan University in China have reported the manipulation of thermal stress distribution to suppress Ag agglomeration and improve the optoelectronic performance of high-power flip-chip light-emitting diodes (FCLEDs). “We reveal the mechanism of Ag agglomeration appearing at the edge of the chip due to high-temperature annealing by simulations and experiments. Besides, we propose a strategy to manipulate the stress distribution by adjusting the thickness of the TiW diffusion barrier layer, which effectively solves the Ag agglomeration problem and promotes the performance of high-power FCLEDs.” said Shengjun Zhou, who directed the research.

GaN-based LEDs have been attracting great attention from industry and academia due to their excellent optoelectronic performance, low power consumption and long operating lifetime. Within the different LED chip configurations, flip-chip technology demonstrates several unique benefits in lighting applications, including higher light extraction efficiency and better heat dissipation. To realize p-type Ohmic contact with a simultaneous lower specific contact resistance and higher optical reflectance is essential for improving optoelectronic performance of FCLEDs. Ag offers an ideal choice for reflective Ohmic contact layer due to its low resistivity, high thermal conductivity and high optical reflectivity. However, Ag film is prone to agglomerating during the annealing process, leading to degradations to performance and reliability of FCLEDs, which has constrained the development of FCLEDs for a long time.

The researchers reveal the underlying mechanism for the edge-concentration of Ag agglomeration by modeling the stress distribution of the chips in high-temperature annealing process. They propose a practical strategy to manipulate the thermal stress distribution by adjusting the thickness of TiW diffusion barrier layer. Furthermore, a lower specific contact resistance is obtained by inserting an ITO layer between Ag and p-GaN as the contact layer. The optimised FCLED shows a 0.17 V drop in forward voltage and about 3 percent improvement in light output power at an injection current of 350 mA. This research is of great value in enhancing the performance of high-power FCLEDs and promoting their use in solid-state lighting, automotive front lighting, and other applications.

Reference

'Enhanced p-type Ohmic contact performance in FCLEDs by manipulating thermal stress distribution to suppress Ag agglomeration' by Ke Sun et al; Applied Physics Letters 122 (20): 202104 (2023)