Roller printing for micro-LED displays

Researchers show how continuous roller printing can precisely transferr 75,000 GaN chips in single shot

Researchers, led by Eleni Margariti from the University of Strathclyde in the UK, have demonstrated a continuous roller printing process that can pick up and transfer over 75,000 micrometer-scale semiconductor devices in a single roll with very high accuracy. They say that the new method paves the way to creating large-scale arrays of optical components and could be used to rapidly manufacture micro-LED displays.

Micro-LED display technology is of great interest because it can accomplish highly accurate colour rendering with high speed and resolution while using little power. These displays can be applied in a wide range of formats including smartphone screens, virtual and augmented reality devices and large displays several meters across. For larger micro-LED displays, in particular, the challenges of integrating millions of tiny LEDs — which are sometimes smaller than a grain of fine sand — onto an electronic control backplane are enormous.

“Transferring micrometer-scale semiconductor devices from their native substrate to a variety of receiving platforms is a challenge being tackled internationally by both academic research groups and industries,” said research team leader Margariti. “Our roller-based printing process offers a way to achieve this in a scalable manner while meeting the demanding accuracy necessary for this application.”

In the journal Optical Materials Express, the researchers report that their new roller technology can match the designed device layout with an accuracy of less than 1 micron. The setup is also inexpensive and simple enough to be constructed in locations with limited resources.

“This printing process could also be used for other types of devices including silicon and printed electronics such as transistors, sensors and antennas for flexible and wearable electronics, smart packaging and radio-frequency identification tags,” said Margariti, who developed the new printing process. “It could also be useful for making photovoltaics and for biomedical applications such as drug delivery systems, biosensors and tissue engineering.”

Large-scale device transfer

“We wanted to improve the transfer of large numbers of semiconductor devices from one substrate to another to improve the performance and scaling of electronic systems used in applications such as displays and on-chip photonics, where the aim is to combine various materials that manipulate light on a very small scale,” said Margariti. “To be used for large-scale manufacturing, it is crucial to use methods that can transfer these devices efficiently, accurately and with minimal errors.”

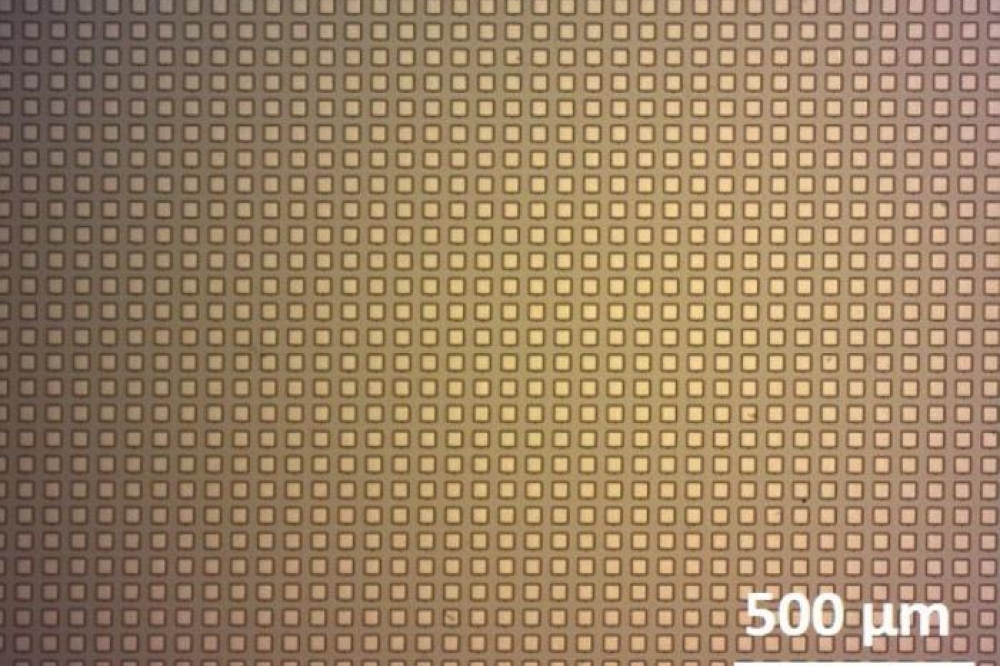

The new approach starts with an array of tiny devices that are loosely attached to their growth substrate. The surface of a cylinder containing a slightly sticky silicone polymer film is then rolled over the suspended array of devices, allowing adhesive forces between the silicone and semiconductor to detach the devices from their growth substrate and array them on the cylinder drum. Because the printing process is continuous it can be used to simultaneously print numerous devices, which makes it highly efficient for large-scale production.

“By carefully selecting the properties of the silicone and receiving substrate surface and the speed and mechanics of the rolling process, the devices can be successfully rolled over and released onto the receiver substrate while preserving the spatially arrayed format they had on the original substrate,” explained Margariti. “We also developed a custom analysis method that scans the printed sample for defects and provides the printing yield and positioning accuracy in just minutes.”

The researchers tested the new approach with GaN on silicon semiconductor structures. They were able to transfer more than 99 percent of the devices in an array of over 76,000 individual elements with a spatial precision below a micron with no significant rotational errors.

Next, the researchers are working to further improve the accuracy of the printing process while also scaling up the number of devices that can be transferred at once. They also plan to test the method’s ability to combine different types of devices onto the same receiving platform and determine if it can be used to print to specific locations of the receiving platform.

Reference

'Continuous roller transfer-printing and automated metrology of >75,000 micro-LED pixels in a single shot' by E. Margariti et al; Opt. Mater. Express vol. 13, Issue 8, pp. 2236-2250 (2023).