SemiQ to unveil 1200V half-bridges at PCIM

Company to showcase QSiC modules in S3 packages and Known-Good-Die (KGD) screening process

SemiQ, a developer of high voltage SiC devices, will show its latest power solutions and recently launched Known-Good-Die (KGD) screening process at PCIM Europe 2024 in Nuremberg from June 11-13, 2024.

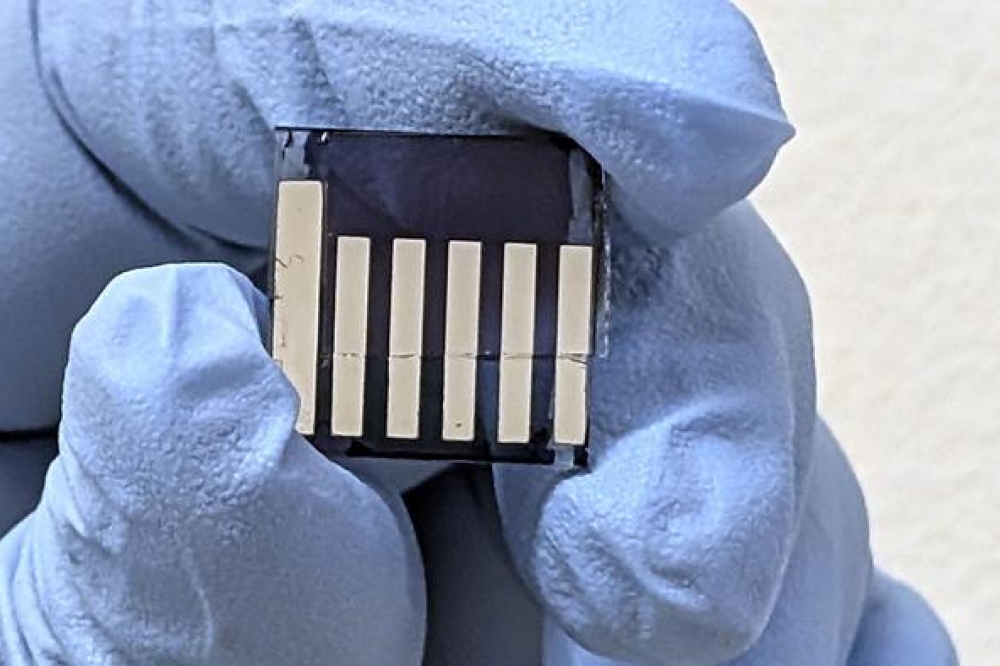

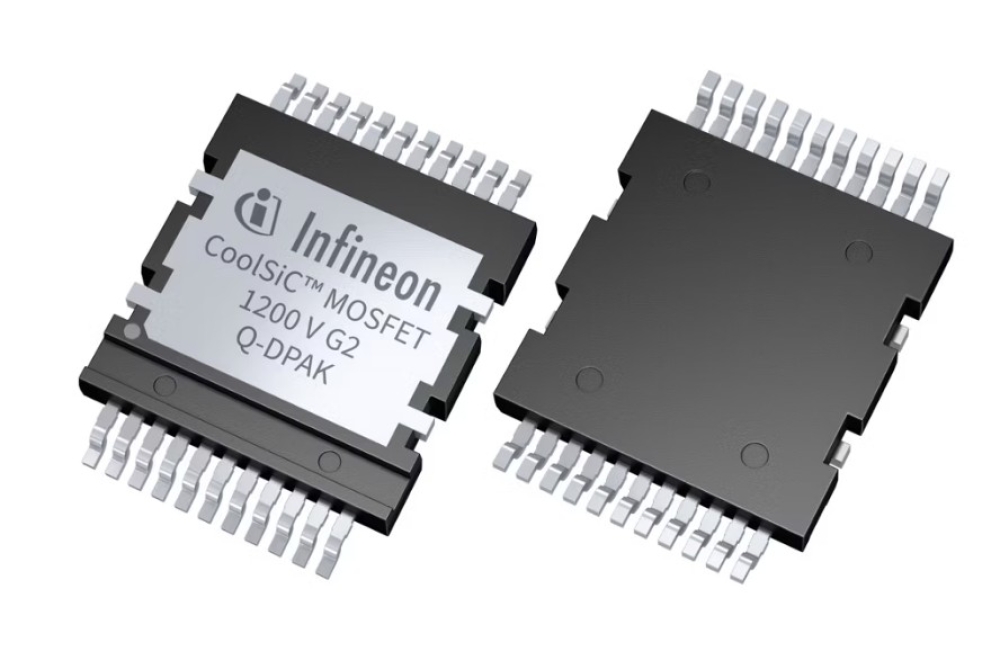

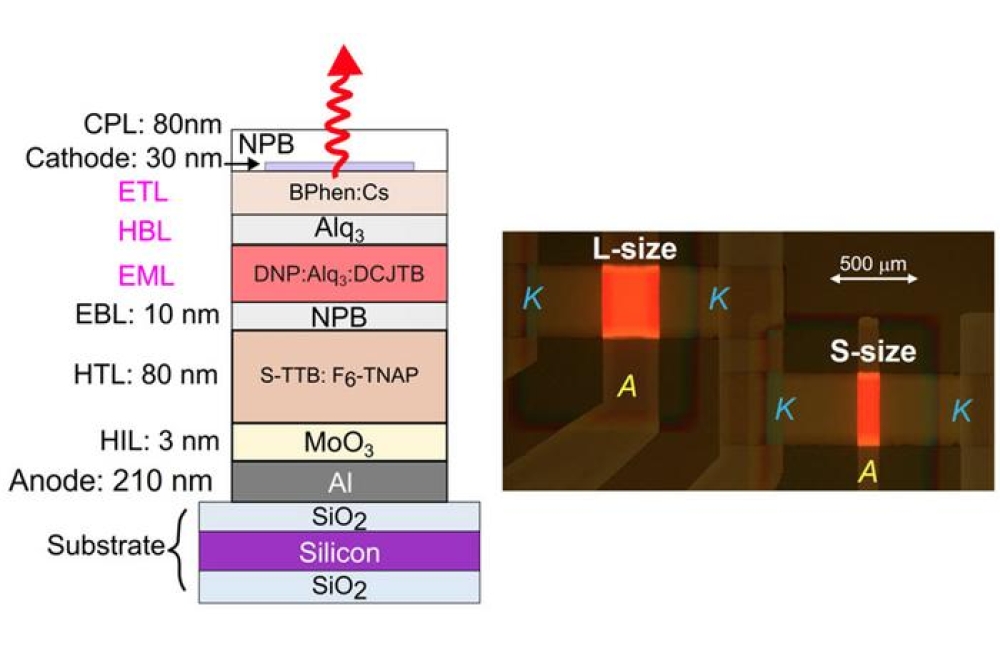

During the event SemiQ will debut the latest addition to its QSiC family of high-speed-switching MOSFET half-bridge modules in S3 packages, which offer enhanced design flexibility and performance in current applications.

Featuring industry-standard 62mm footprints and standing at 26.3mm in height, the new power modules address the size, weight and power demands of challenging applications, ranging from induction heaters, welding equipment and uninterruptible power supplies (UPS) to photovoltaic and wind inverters, energy storage systems, high-voltage DC-DC converters and battery charging systems for electric vehicles (EVs). They are available in 600A (GCMX003A120S3B1-N) and 400A (GCMX005A120S3B1-N). Visitors will also be able to see SemiQ’s QSiC family of 1200V modules in SOT-227, half-bridge and full-bridge options.

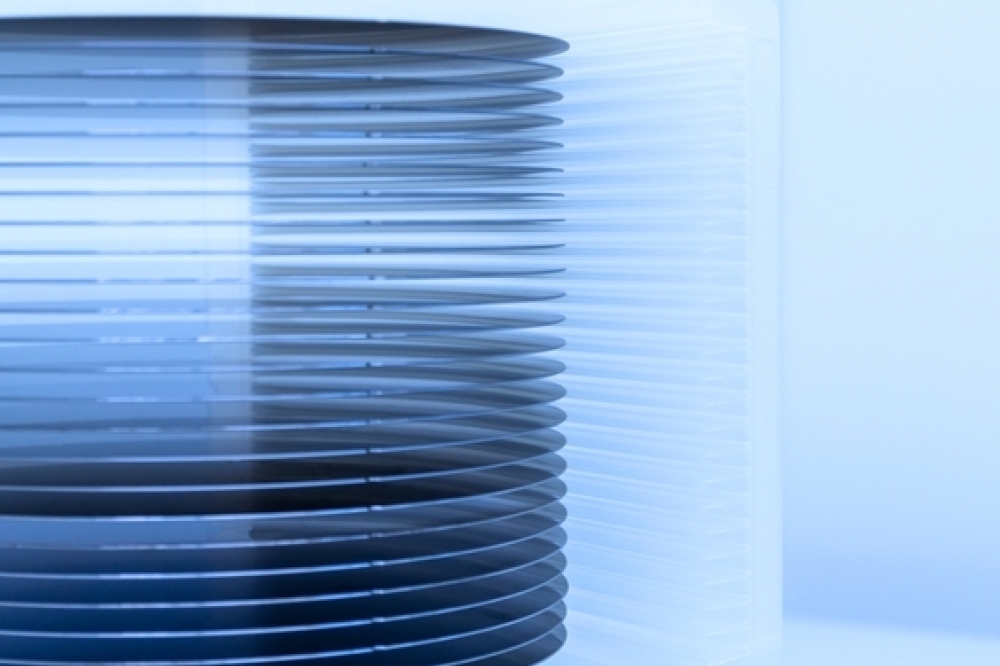

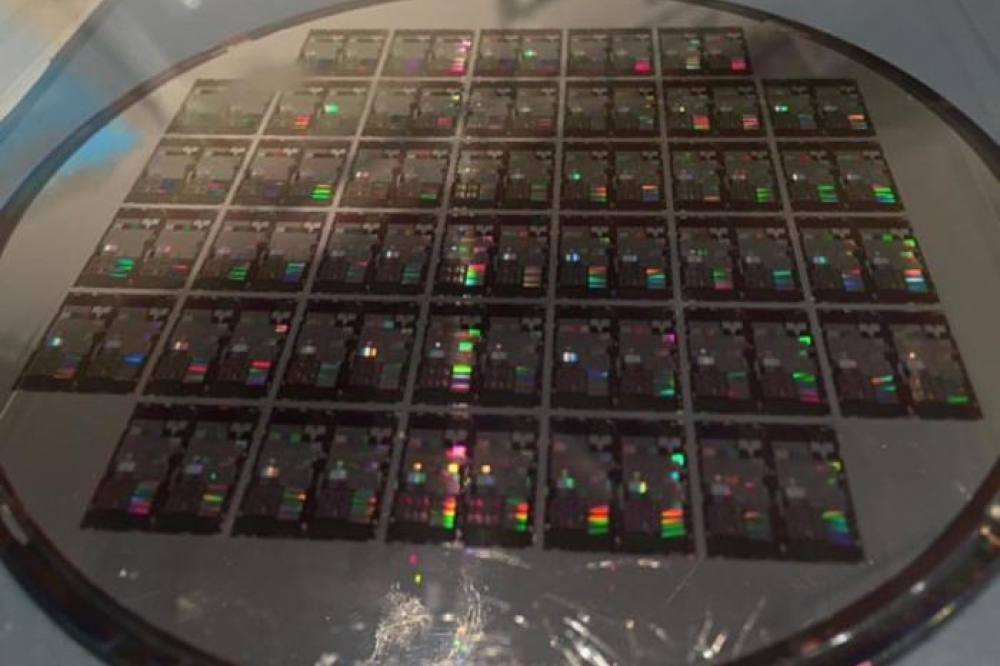

Attendees will also have the unique opportunity to learn more about the recently launched Known-Good-Die (KGD) screening program and see SemiQ’s MOSFET bare die on Known-Good-Die UV tape array for the first time.

The KGD process delivers high-quality, electrically sorted and optically inspected advanced SiC MOSFET technology ready for back-end processing and direct die attachment.

“We're thrilled to participate at PCIM, a significant event in the power electronics industry," said Timothy Han, president of SemiQ. "With the expansion of our QSiC family, our goal is to offer a comprehensive, high-performance SiC portfolio across various sectors and offer customised solutions for cutting-edge designs. Our continued dedication to rigorous testing and quality assurance, delivering unmatched reliability, is embodied in our new KGD program which we will be demonstrating at the event.”