Cambridge GaN signs agreement with Taiwan's ITRI

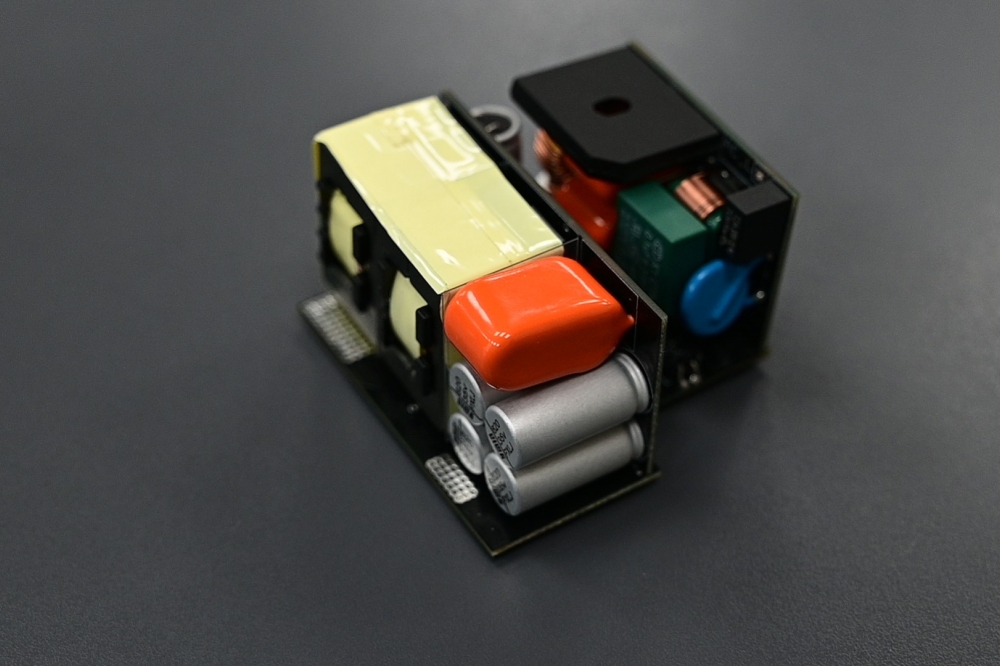

USB-PD adaptor exceeding 30 w/in3 for e-mobility, tools, notebooks and cell phones is the first target

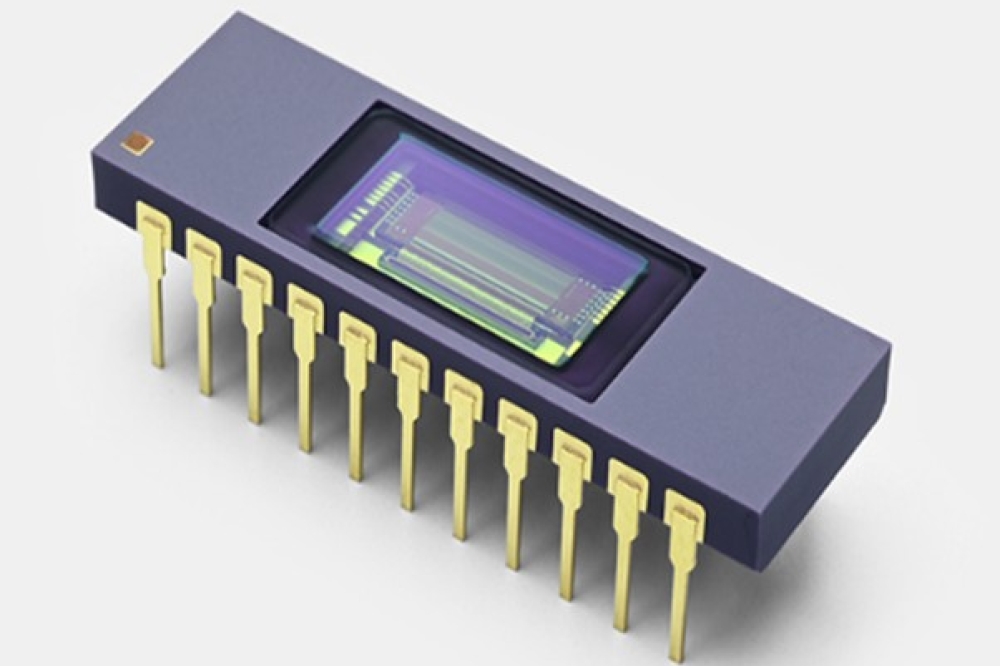

Cambridge GaN Devices (CGD) has signed a Memorandum of Understanding with Industrial Technology Research Institute (ITRI) of Taiwan to solidify a partnership in developing high performance GaN solutions for USB-PD adaptors. The MoU also covers the sharing of domestic and international market information, joint visits to potential customers and promotion.

Andrea Bricconi, chief commercial officer GGD commented: “We are excited to partner with ITRI, an organisation with a power solution research team that is very experienced in developing power solutions and holds many patents. We will be demonstrating some of their board designs at our booth at the upcoming PCIM show in Nuremberg in June. These products utilise CGD's unique IC chip architecture and ITRI's patented designs to achieve product size reduction, high efficiency and power density, and cost competitiveness.”

Wen-Tien Tsai, leader of commercial power design team, GEL/ITRI said: “CGD’s IC-enhanced GaN – ICeGaN – is a novel platform that improves ease-of-use, facilitates smart temperature control and enhances gate reliability. We are excited to include these benefits in our new power designs.”

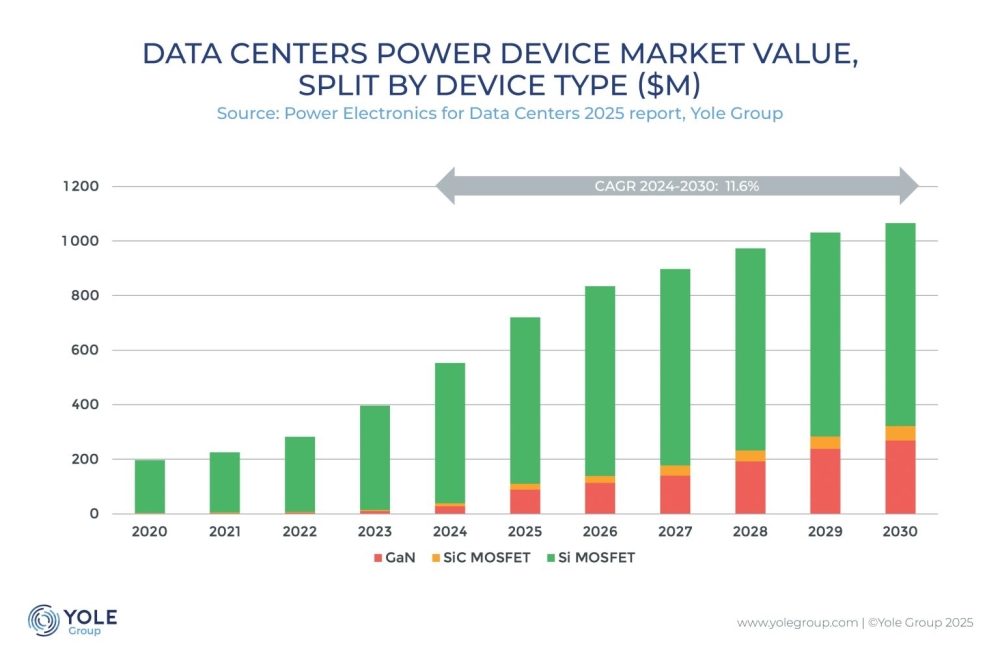

According to WBG analysts, Yole Group, the GaN market is expected to exceed $1B, with key growth in the applications of comms power supplies, and automotive DC/DC converters and on-board chargers. However, the first commercialised product in the market to adopt GaN devices has been USB-PD adaptors, and it is this market that the first designs from the partnership will address. Specifically, the agreement covers the development of power solutions in the 140-240 W range with power densities exceeding 30 W/in3 for e-mobility, power tools, notebook and cell phone applications.