Onsemi chooses Czech Republic for SiC production

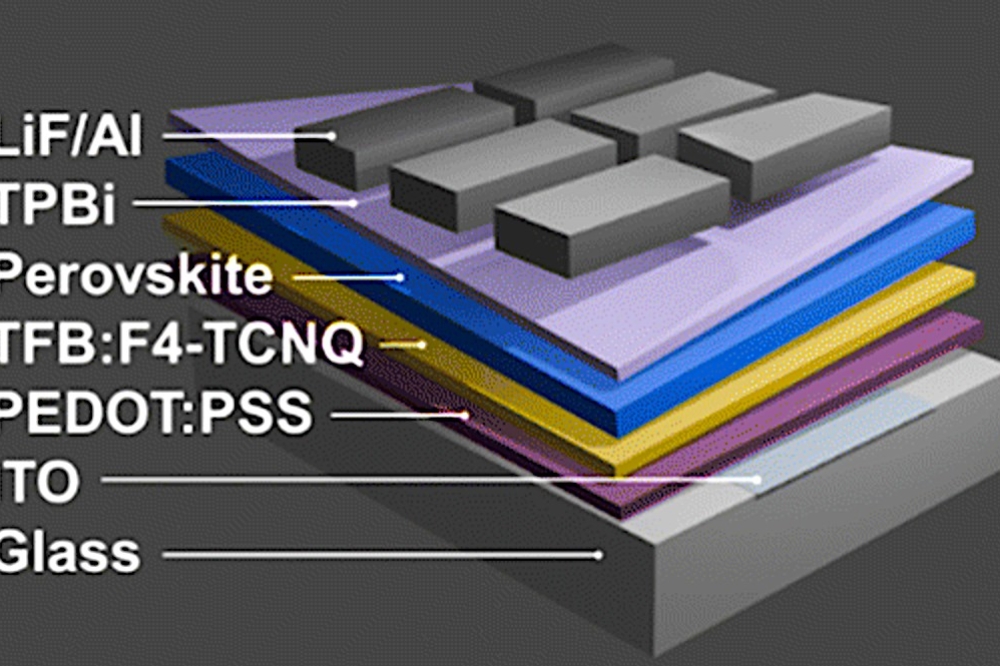

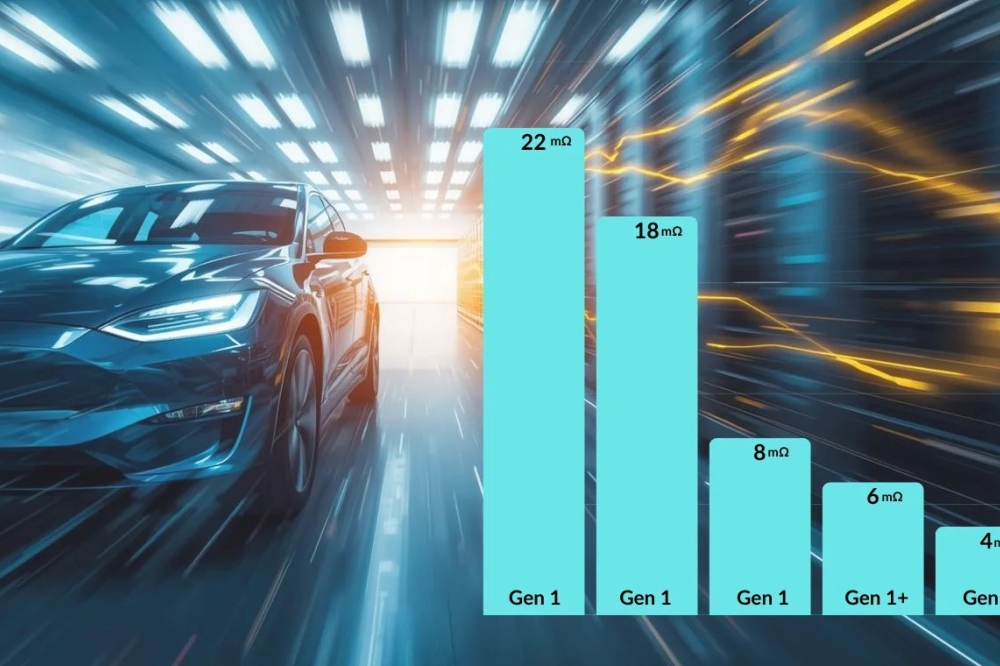

Onsemi has announced plans to establish a state-of-the-art, vertically integrated SiC manufacturing facility in the Czech Republic.

Onsemi’s plan to expand SiC manufacturing with a multi-year brownfield investment of up to $2 billion is part of the company’s previously disclosed long-term capital expenditure target.

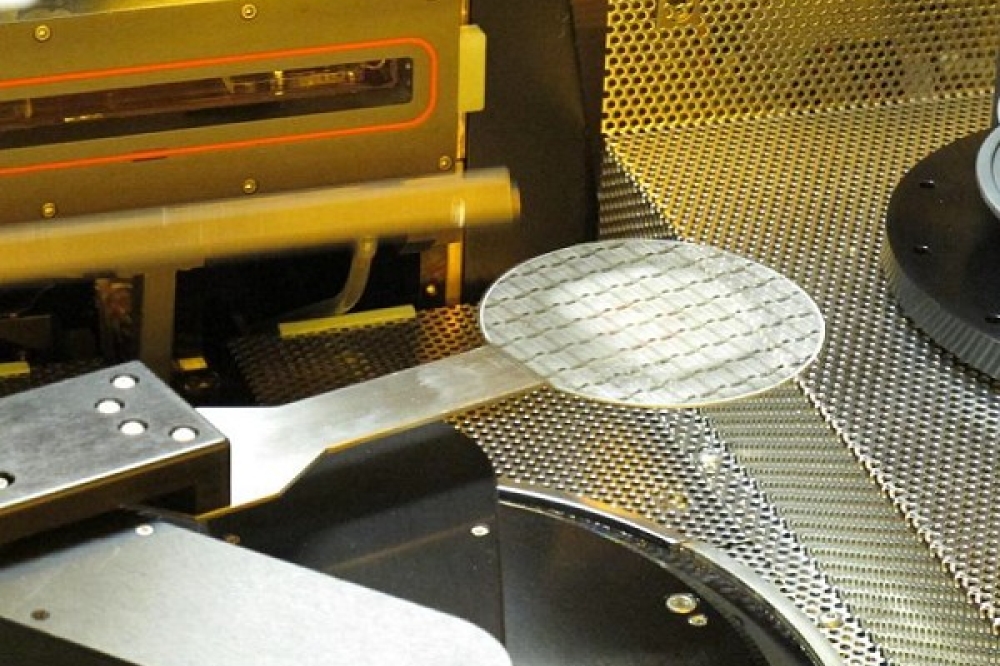

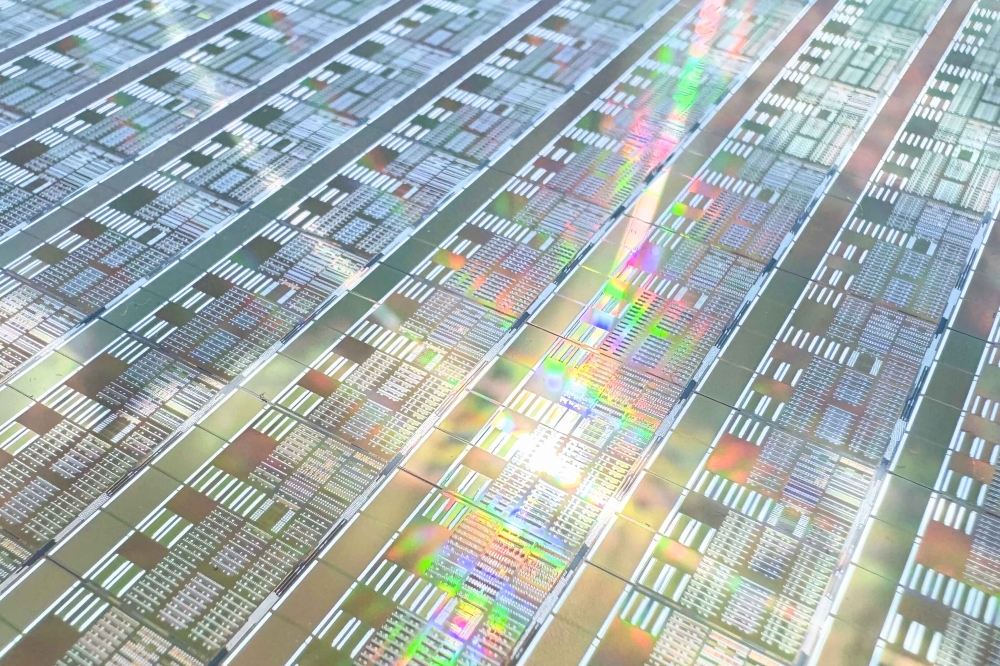

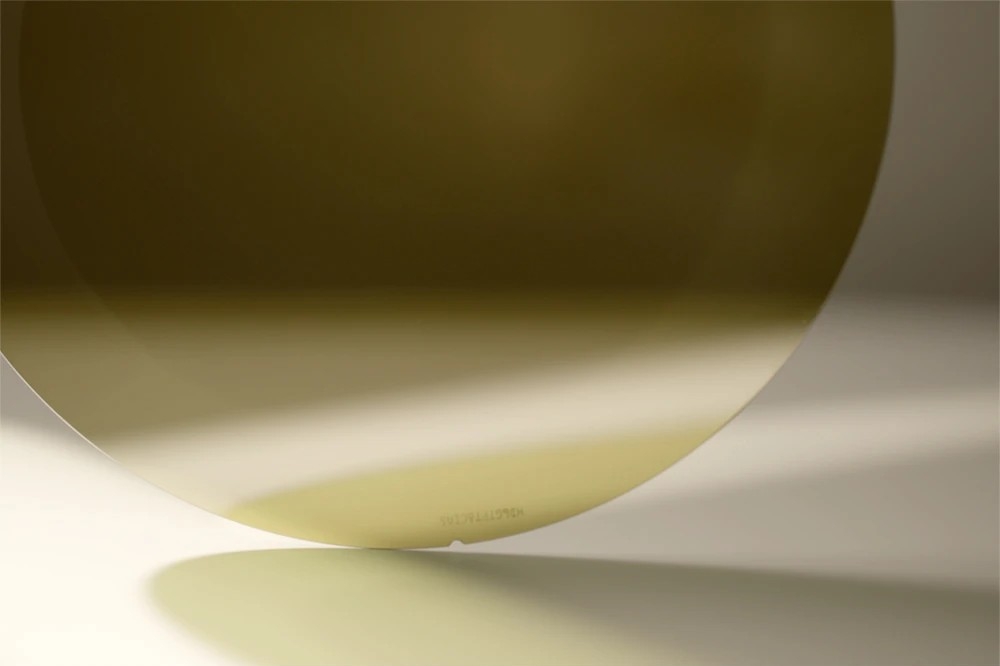

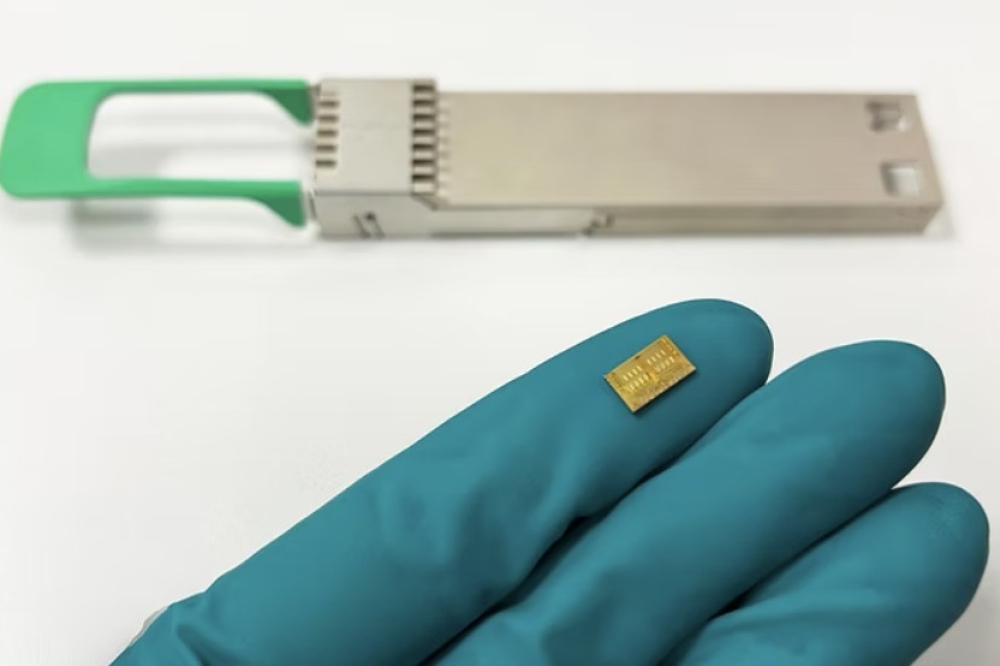

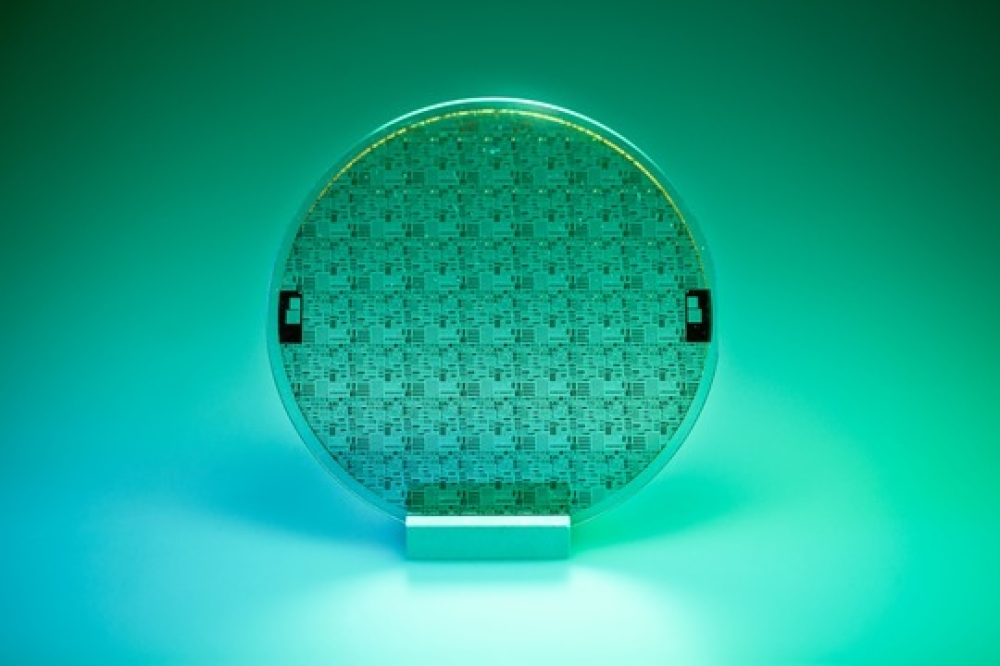

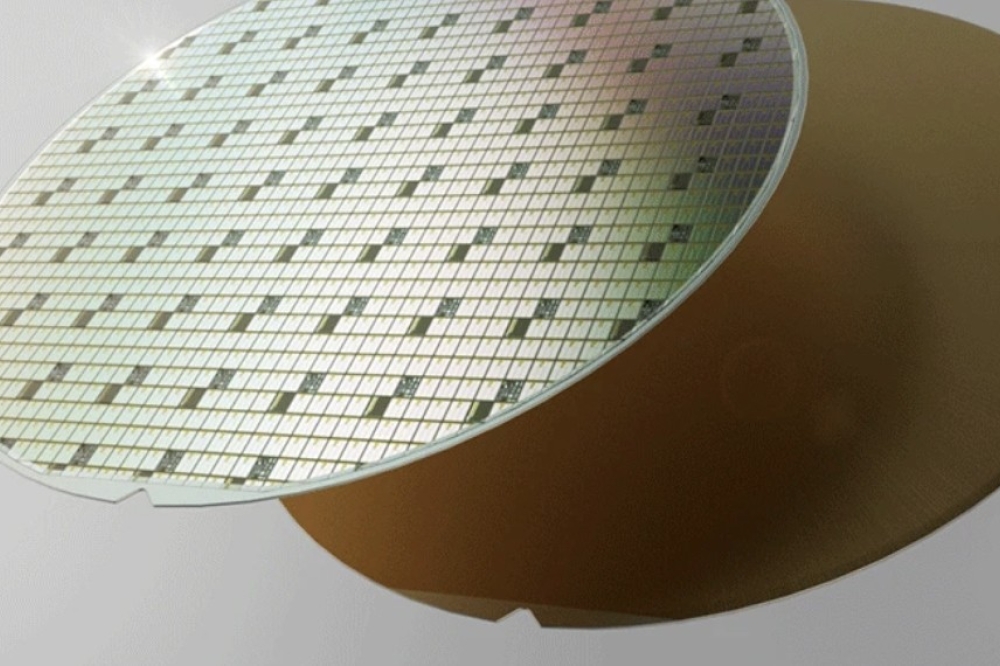

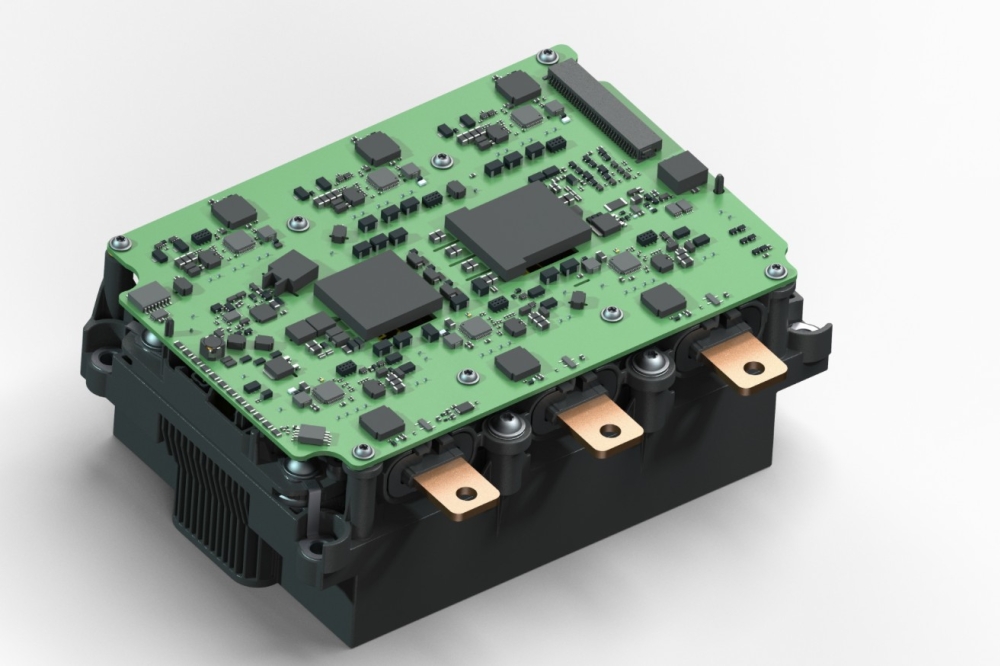

This investment would build on the company’s current operations in the Czech Republic, which include silicon crystal growth, silicon and SiC wafer manufacturing (polished and EPI) and a silicon wafer fab. Today, the site can produce more than three million wafers annually, including more than one billion power devices. Upon completion, the operation would contribute annually more than $270 million to the country’s GDP.

"Our brownfield investment would establish a Central European supply chain to better service our customers’ rapidly increasing demand for innovative technologies that improve the energy efficiency in their applications,” said Hassane El-Khoury, president and CEO, Onsemi.

“Through a close collaboration with the Czech government, the expansion would also enhance our production of intelligent power semiconductors that are essential to helping ensure the European Union is able to achieve its ambitions to significantly reduce carbon emissions and environmental impact.”

“Onsemi’s decision to expand in Czechia is a clear confirmation of our country’s attractiveness for foreign investment and will bring significant momentum for the development of our economy,” said Jozef Síkela, Minister of Industry and Trade of the Czech Republic. “This investment not only strengthens our position in the semiconductor field but can also contribute to the development of the automotive industry and help us with its adaptation to the rise of electromobility.”

Pending all final regulatory and incentive approvals, this would be one of the largest private sector investments in the Czech Republic’s history.

Onsemi is one of the first companies to invest in advanced semiconductor manufacturing in the Central European region. With this investment, the company says it would contribute to the strategic positioning of the region within the EU’s semiconductor value chain and demonstrate that all EU countries can benefit from the European Chips Act.