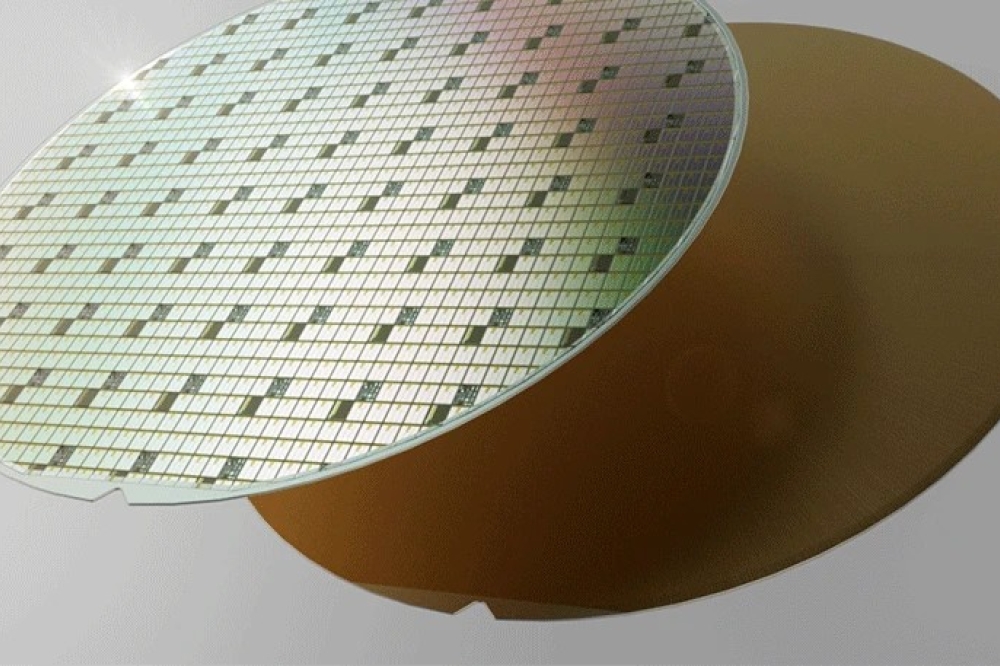

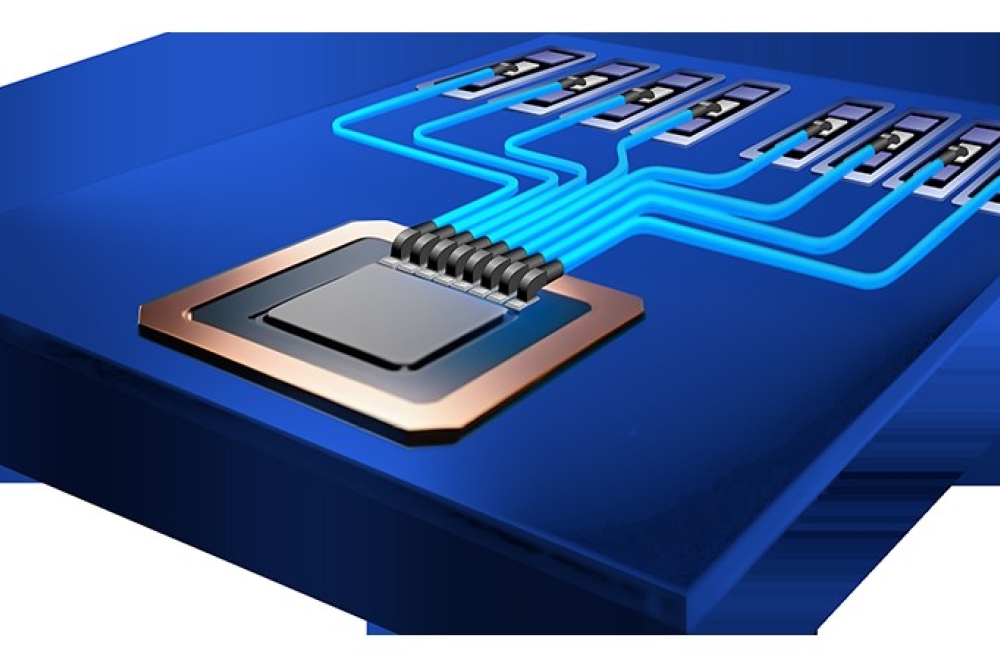

Fraunhofer IMS opens up photonic integration capabilities

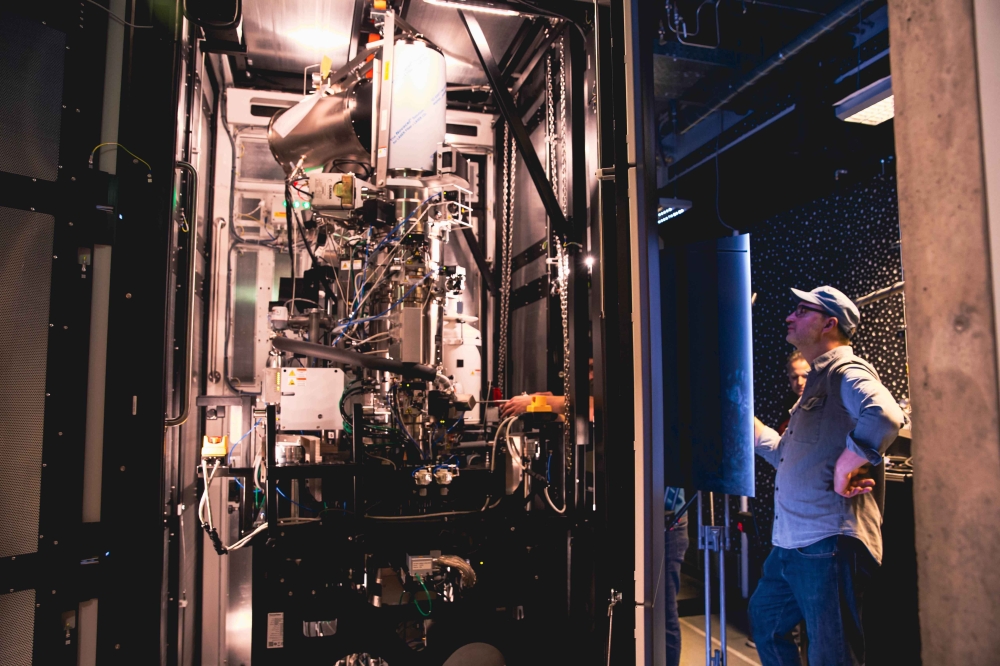

Fraunhofer IMS is opening up its photonic integration capabilities to participants who would like to engage in engineering runs (starting Q1 2025) to create their own PIC designs in a high-quality clean room.

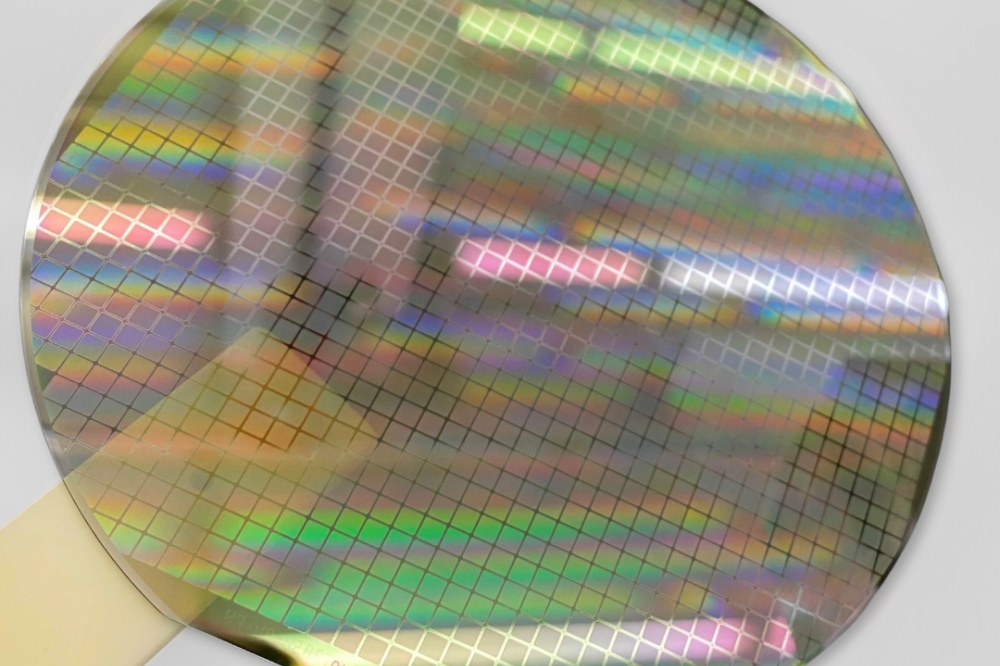

The Fraunhofer IMS SiN-based photonic platform (built on 200 mm wafers) supports low-loss, broad-wavelength applications. It offers the possibility of novel quasi-monolithic integration with a wide range of waveguide materials, including, for example, SiN, tantalum pentoxide (Ta2O5), covering visible to mid-infrared wavelengths from 370 nm to 3 µm. Current photonic components include couplers, waveguides, and interferometers, with the option for custom designs.

Fraunhofer IMS says it offers strong support for technology, device, and circuit simulations, considering packaging and system-level needs.

With expertise in microelectronics, micro-electromechanical systems (MEMS), and photonics, Fraunhofer IMS focuses on post-CMOS integration of PICs for smart sensor systems. This includes working with external foundry wafers for applications in optical computing, biosensors, and on-chip quantum photonics.

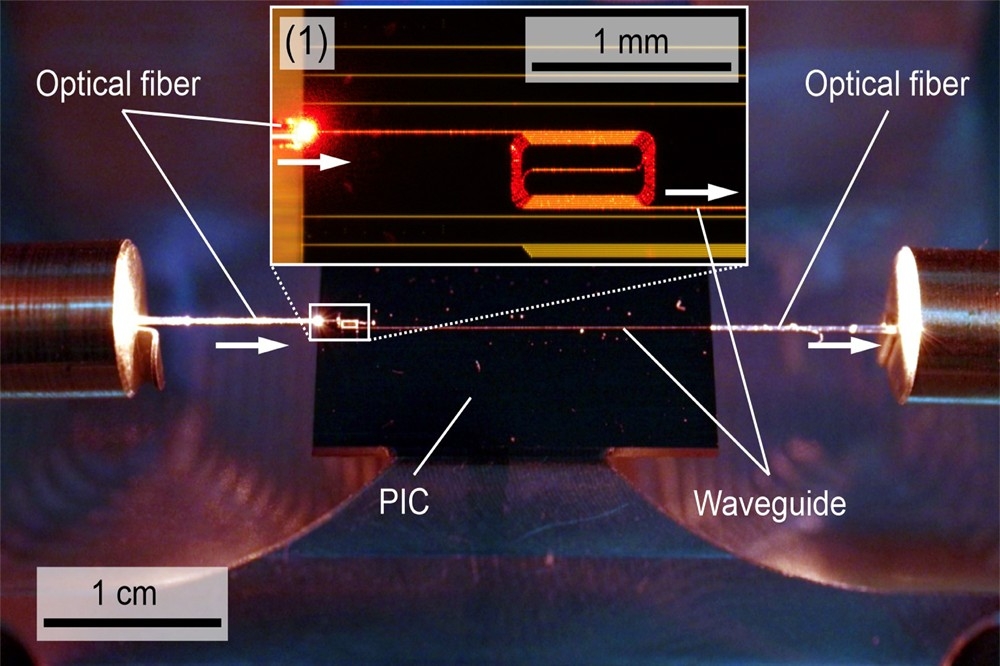

Photograph above shows edge coupling into and out of a cutback structure using 633 nm light. Inset (1): Microscope image of the cutback structure and coupling area.