Trikon Wins Multiple Orders From New GaAs Wireless Chip Fab In Asia

PVD, PECVD and Plasma Etch systems ordered

Newport, Wales, UK. Trikon Technologies, Inc. (OTC-BB: TRKN) a technology leader in semiconductor processing equipment, today announced it had received an order from a new gallium arsenide (GaAs) facility in Asia set to manufacture wireless devices. The order comprises a Sigmaâ PVD system for front and back-side metalization, a Deltaâ for PECVD silicon nitride passivation and Omegaâ ICP etch systems for both front-side thin film and through-wafer plasma etching.

"Trikon s systems are ideally suited to compound semiconductor processing," said Nick Carrington, Trikon senior vice president of sales. "Trikon offers the advantage of a one-stop shop for many customer s critical plasma process requirements; integrated processes that add value for our customers. Our systems offer outstanding process flexibility, excellent factory backup and are compact and reliable. Trikon is an industry veteran bringing many years of experience to the rapidly expanding markets for wireless and optoelectronics device manufacture."

Mr. Carrington continued, "Compound semiconductor device makers demand production equipment with the same quality of automation, reliability and back-up that the leading silicon device makers require. Trikon s ability to win business for plasma etch, CVD and PVD equipment for mainstream silicon processing demonstrates the quality of Trikon s products and operations, differentiating Trikon from many of its competitors in the compound semiconductor equipment market."

Trikon s new technology products include: Planar fxPÔ Low K Flowfill™.. An advanced low-k dielectric deposition system capable of both gap fill and planarization enabling the low-k advantage of increased device speed to be brought to existing aluminum metalization devices as well as copper.

- more - Sigma® fxPÔ PVD. A metalization system offering high throughput and reliability with advanced process modules for high uniformity PVD, metal plug (Forcefill®) and advanced barrier deposition processes including ionized PVD.

Omega® M0RI™. An advanced high density plasma etch chamber on a small footprint platform. The Omegaâ etcher can be configured with two chambers offering plasma etching and dedicated post etch processing or dual chambers for higher throughput.

Trikon have recently made announcements including: · LSI Logic orders a Planar fxPÔ Low K Flowfill™ and a M0RI™ Omega® plasma etcher for GflxÔ (0.13-micron drawn) process technology. Reports 36% speed improvement of G12Ô (0.18 micron drawn) using FlowfillÔ · Repeat orders from TriQuint for PVD and plasma etch equipment for wireless device manufacture · Leading North American communications company orders 8 plasma etch and PECVD systems for optoelectronics device manufacture on InP wafers · Exchange of bonds and preferred notes for common stock reducing dividend payable in fiscal 2000 by $1.1m and reducing interest payable by $72,000 · Tower Semiconductor Ltd. order additional Flowfillâ and Forcefillâ systems for production expansion · 1999 financial results. Product sales up 92% on 1998

About Trikon Technologies Trikon, www.trikon.com offers a broad range of semiconductor processing equipment for silicon and compound device production. Trikon has patents and patents pending on processes and equipment including Flowfillâ and Low K Flowfill™ and continues to develop low-k chemistries and processes for advanced applications. Trikon s systems are used for three of the major processing steps in the manufacture of a semiconductor device: plasma etching and dielectric and metal vapor deposition. Products include: Low K Flowfill™ for advanced low-k insulator deposition, Sigma® fxP for advanced metal deposition including barrier layers and M0RI™ high-density plasma etchers.

"Safe Harbor" Statement Under the Private Securities Litigation Act of 1995: This news release contains certain forward-looking statements, including, but not limited to, statements relating to the continued strength in demand for semiconductor production equipment and the status of Trikon s products and their acceptance in the marketplace. These forward-looking statements are subject to various risks and uncertainties that could cause results to differ materially, including, but not limited to, (1) that the semiconductor industry will experience conditions, such as changes in demand for various types of semiconductors, that will affect the demand for semiconductor production equipment and Trikon s products, (2) that Trikon will not adequately respond to technological developments impacting the semiconductor industry, (3) market acceptance of Trikon s products will not be forthcoming. These factors are not intended to represent a complete list of all risks and uncertainties inherent in the Company s business, and should be read in conjunction with the more detailed cautionary statements included in the company s SEC reports, including, without limitation, its annual report on Form 10-K, quarterly reports on Form 10-Q and current reports on Form 8-K.

Contact:

Carl Brancher

Trikon Technologies

44 (0) 1633 414111 (U.K.)

carl.brancher@trikon.com

Carl Brancher

Trikon Technologies

44 (0) 1633 414111 (U.K.)

carl.brancher@trikon.com

E-mail: carl.brancher@trikon.com

Web site: http://www.trikon.com

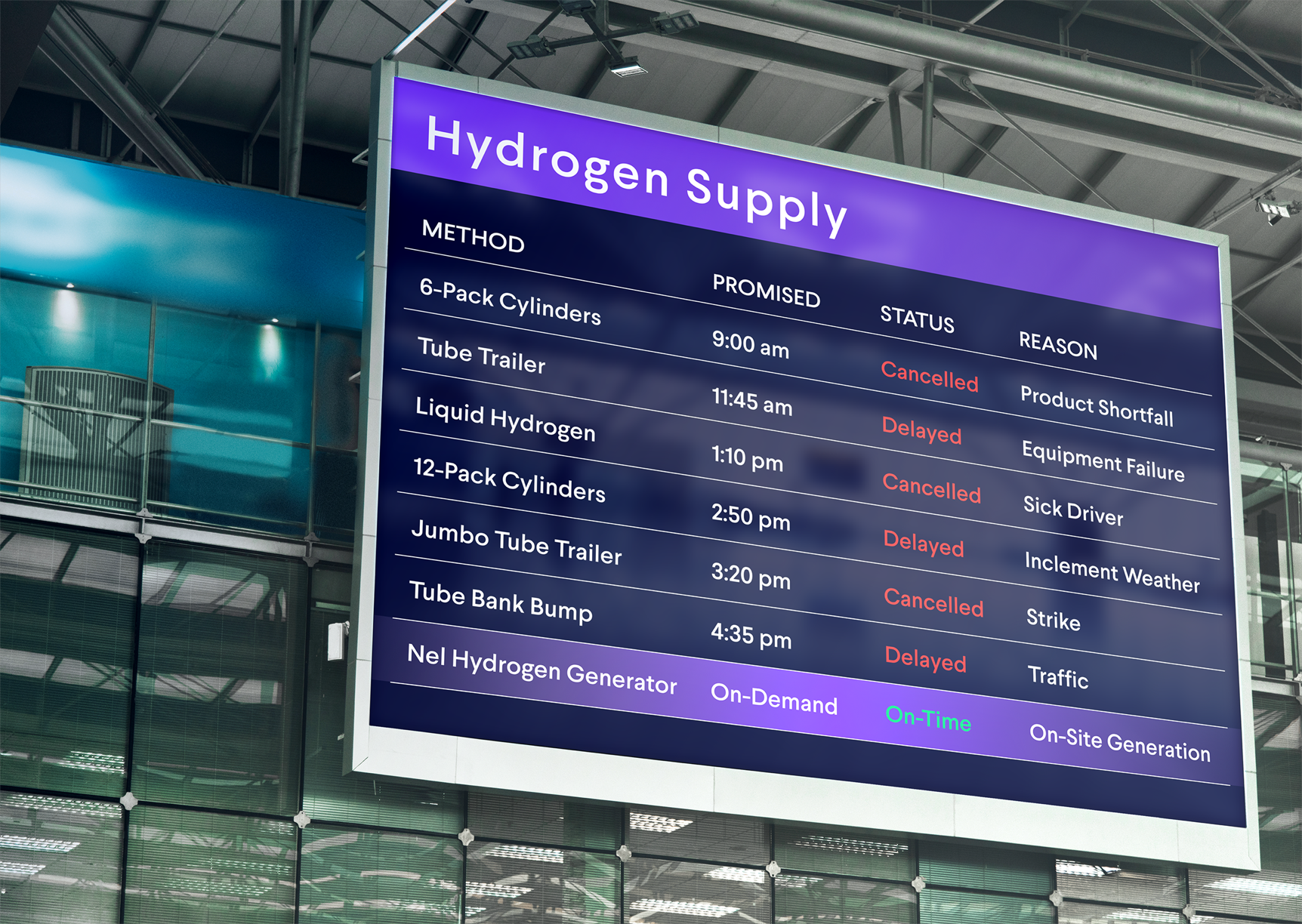

Secure Your Hydrogen Supply

A study supply of high-purity hydrogen is critical to semiconductor fabrication. Supply chain interruptions are challenging manufacturers, leading to production slowdowns and stoppages. On-site hydrogen generation offers a scalable alternative for new and existing fabs, freeing the operator from dependence on delivered gas.Plant managers understand the critical role that hydrogen plays in semiconductor fabrication. That important job includes crystal growth, carrier gas, wafer annealing, and in the emerging Extreme UV Lithography (EUV) that will enable new generations of devices. As the vast need for semiconductors grows across all sectors of world economies, so does the need for high-purity hydrogen.

Take control with Nel on-site hydrogen generation.

Read more

.jpeg)