News Article

II-VI to speed up laser optic production with Veeco IBD tool

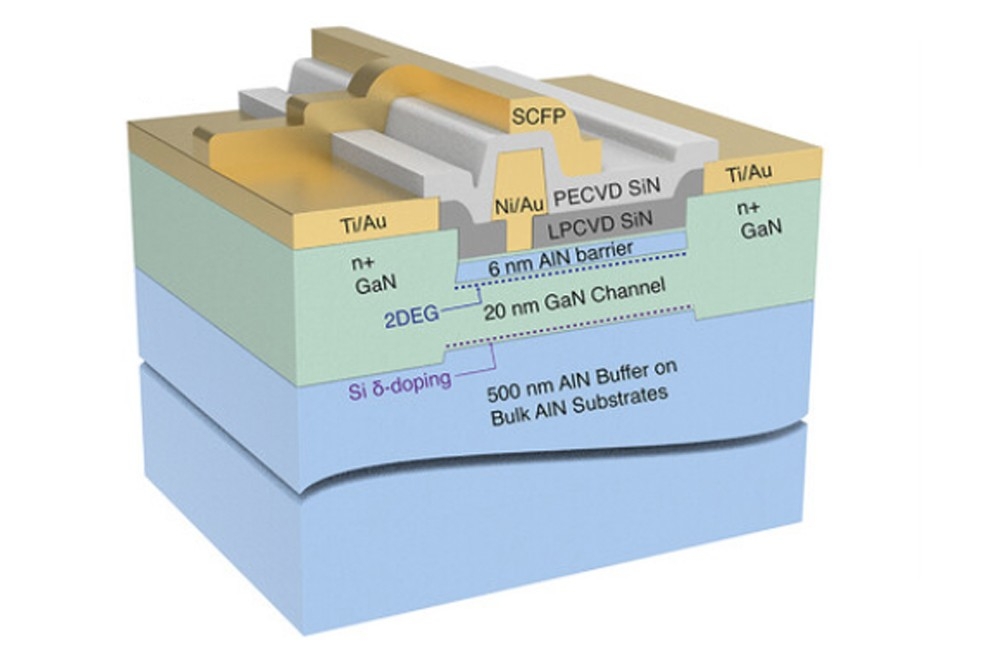

The SPECTOR-HT system is claimed to offer higher depostion rates than other tools

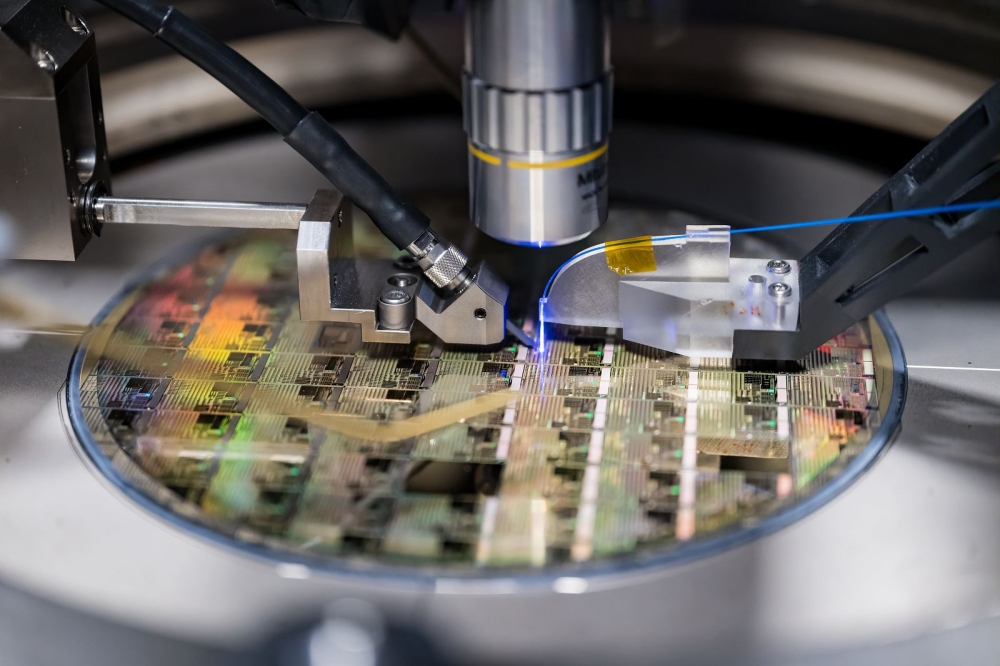

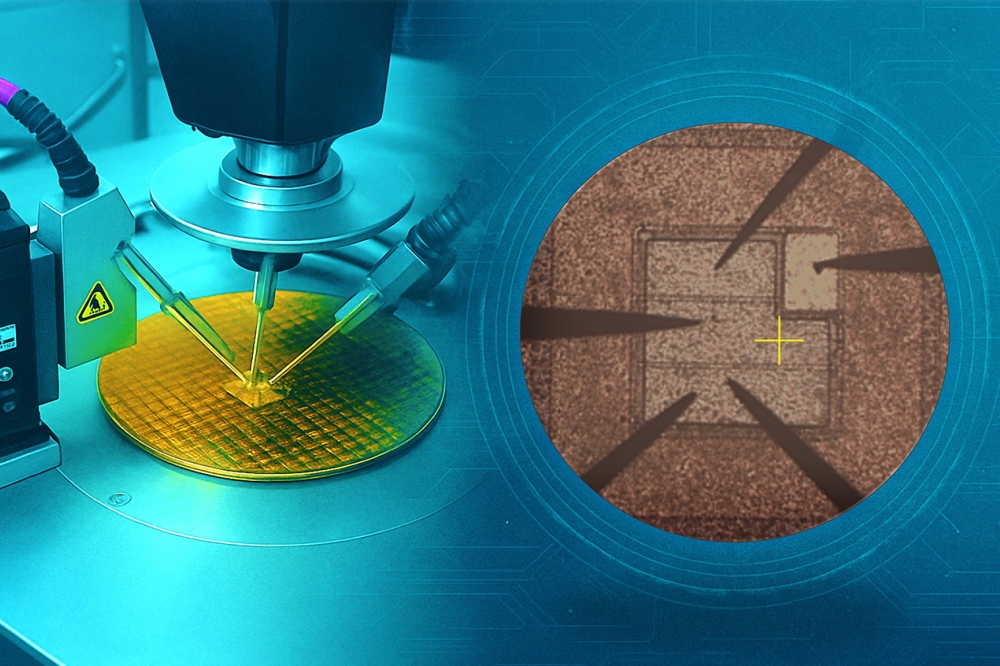

II-VI Incorporated has ordered the SPECTOR-HT Ion Beam Deposition (IBD) System and added Veeco’s new Quest Optical Monitor, for use in its high-volume production of laser optics.

Veeco says its SPECTOR-HT IBD System produces high quality optical thin films with improved levels of productivity and throughput.

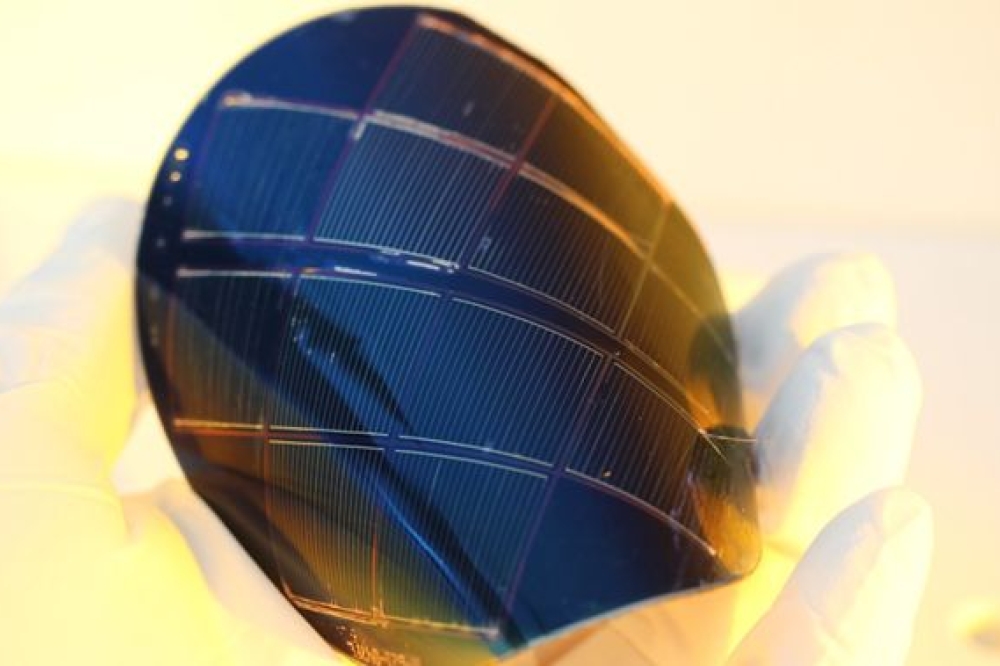

SPECTOR-HT IBD reactor

The Quest Optical Monitor provides up to ten times improvement in layer thickness accuracy compared to previous generations for precise manufacturing control.

“Veeco’s SPECTOR-HT IBD System allows us to deliver high quality laser optics faster by achieving superior deposition rates while maintaining exceptional film qualities,” says Mark West, General Manager, II-VI Infrared. “The Veeco Quest Optical Monitor upgrade is an incredible breakthrough. It ensures we will have a repeatable, highly productive operation using the latest technology, enabling us to produce the highest quality laser optics.”

Headquartered in Saxonburg, Pennsylvania, II-VI specialises in engineered materials and optoelectronic components. Veeco is an focuses on MOCVD, MBE, Ion Beam and other advanced thin film process technologies.

“II-VI is an optical coating leader and their endorsement of the SPECTOR-HT is clear indication of its exceptional value,” continues Jim Northup, Vice President and General Manager of Veeco MBE, Optical Systems and Ion Sources. “As the optics industry seeks faster deposition rates and more repeatable processes, Veeco's SPECTOR-HT IBD System, coupled with the new Quest Optical Monitor, achieves unprecedented levels of productivity by offering the highest throughput for optical thin film manufacturers.”

Veeco says its SPECTOR-HT IBD System produces high quality optical thin films with improved levels of productivity and throughput.

SPECTOR-HT IBD reactor

The Quest Optical Monitor provides up to ten times improvement in layer thickness accuracy compared to previous generations for precise manufacturing control.

“Veeco’s SPECTOR-HT IBD System allows us to deliver high quality laser optics faster by achieving superior deposition rates while maintaining exceptional film qualities,” says Mark West, General Manager, II-VI Infrared. “The Veeco Quest Optical Monitor upgrade is an incredible breakthrough. It ensures we will have a repeatable, highly productive operation using the latest technology, enabling us to produce the highest quality laser optics.”

Headquartered in Saxonburg, Pennsylvania, II-VI specialises in engineered materials and optoelectronic components. Veeco is an focuses on MOCVD, MBE, Ion Beam and other advanced thin film process technologies.

“II-VI is an optical coating leader and their endorsement of the SPECTOR-HT is clear indication of its exceptional value,” continues Jim Northup, Vice President and General Manager of Veeco MBE, Optical Systems and Ion Sources. “As the optics industry seeks faster deposition rates and more repeatable processes, Veeco's SPECTOR-HT IBD System, coupled with the new Quest Optical Monitor, achieves unprecedented levels of productivity by offering the highest throughput for optical thin film manufacturers.”