Mitsubishi develops SBD-embedded SiC MOSFET

New chip structure prevents surge-current crowding and will help to downsize railway traction systems

Mitsubishi Electric has developed a new structure for a SiC MOSFET embedded with a Schottky barrier diode (SBD), which the company has applied to a SiC power module, the FMF 800 DC -66 BEW2 for large industrial equipment such as railways and DC power systems.

Samples began shipping on May 31. The chip's new structure is expected to help downsize railway traction systems as well as make them more energy efficient, and contribute to carbon neutrality through the increased adoption of DC power transmission.

SiC power semiconductors are attracting attention with their capacity to significantly reduce power loss. Mitsubishi Electric, which commercialised SiC power modules equipped with SiC-MOSFETs and SiC-SBDs in 2010, has adopted SiC power semiconductors for a variety of inverter systems, including air conditioners and railways.

The chip integrated with a SiC-MOSFET and a SiC-SBD can be mounted on a module more compactly compared to the conventional method of using separate chips, thus enabling smaller modules, larger capacity, and lower switching loss. It is expected to be widely used in large industrial equipment such as railways and electric power systems.

Until now, the practical application of power modules with SBD-embedded SiC-MOSFETs has been difficult due to their relatively low surge-current capability, 3 which results in the thermal destruction of the chips during surge-current events because surge currents in connected circuits concentrate only in specific chips.

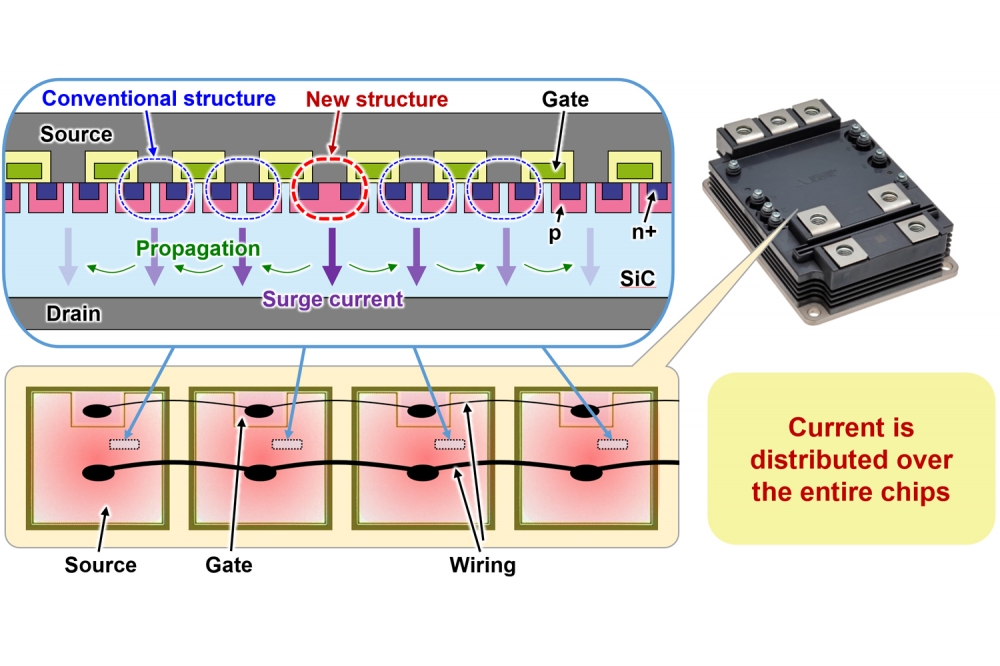

Mitsubishi Electric has now developed the world's first mechanism by which surge current concentrates on a specific chip in a parallel-connected chip structure inside a power module, and a new chip structure in which all chips start energizing simultaneously so that surge current is distributed throughout each chip.

As a result, the power module's surge-current capacity has been improved by a factor of five or more compared to the company's existing technology, which is equal to or greater than that of conventional Si power modules, thus enabling the application of an SBD-embedded SiC-MOSFET in a power module.

In conventional SiC power modules, SiC-MOSFETs are used for switching and SiC-SBDs are used for rectifying, with the two separately manufactured chips being connected in parallel. Mitsubishi Electric's SBD-embedded SiC-MOSFET integrates the two chips by periodically forming the SiC- SBD in the SiC-MOSFET unit cell.

Conventionally, when surge current flows through multiple SBD-embedded MOSFET chips connected in parallel, the surge current is concentrated only on a specific chip, preventing the surge current withstand capability corresponding to the number of parallel chips from being obtained.

Physical and device-simulation analyses have now revealed that surge current is concentrated on a specific chip if the dimensions of that chip's built-in SBD vary even slightly from other chips, which is not uncommon, thereby causing that specific chip to initiate a surge current flow before the other chips. Since the size variation need only be extremely minor, such variations are basically impossible to avoid in normal chip manufacturing processes.

To prevent surge currents from concentrating on specific chips, Mitsubishi has developed a new chip structure in which the built-in SBD is not placed in a unit cell that occupies less than 1 percent of the total chip area. This unit cell has a structure that allows surge current to flow faster than other unit cells with SBDs, and is unaffected by dimensional variations due to the absence of SBDs. Therefore, surge current can start energising simultaneously in the corresponding unit cells of all chips without SBDs.

In addition, because the surge current reduces resistance of the surrounding SiC, the energisation of the surge current is also triggered in the surrounding unit cells where the surge current is energised, in a chain reaction. This phenomenon causes surge current to propagate throughout the entire chip area, starting from the unit cell where the SBD is not present. Consequently, surge current is distributed over all areas of all chips, preventing thermal breakdown of the chip due to the concentration of surge currents on a particular chip, thereby increasing the surge current withstand capability.

Using the new chip structure, the surge current capability of the SBD-embedded SiC-MOSFET in parallel connection has been improved by more than five times compared to the company's existing technology, which is equal to or greater than that of widely used conventional Si power modules.

Furthermore, because of the chain reaction of surge current, a small portion (less than 1 percent) of the total chip area is sufficient for a unit cell without the built-in SBD, and there is no effect on power module characteristics such as low ON-resistance and low switching loss due to the reduced area of the built-in SBD. As a result, chips can be connected in parallel, a requirement for power modules intended for high-power applications such as railways and electric power systems, thus allowing SBD-embedded SiC-MOSFET to be used in power modules.