Soltec and Fraunhofer ISE partner on solar project

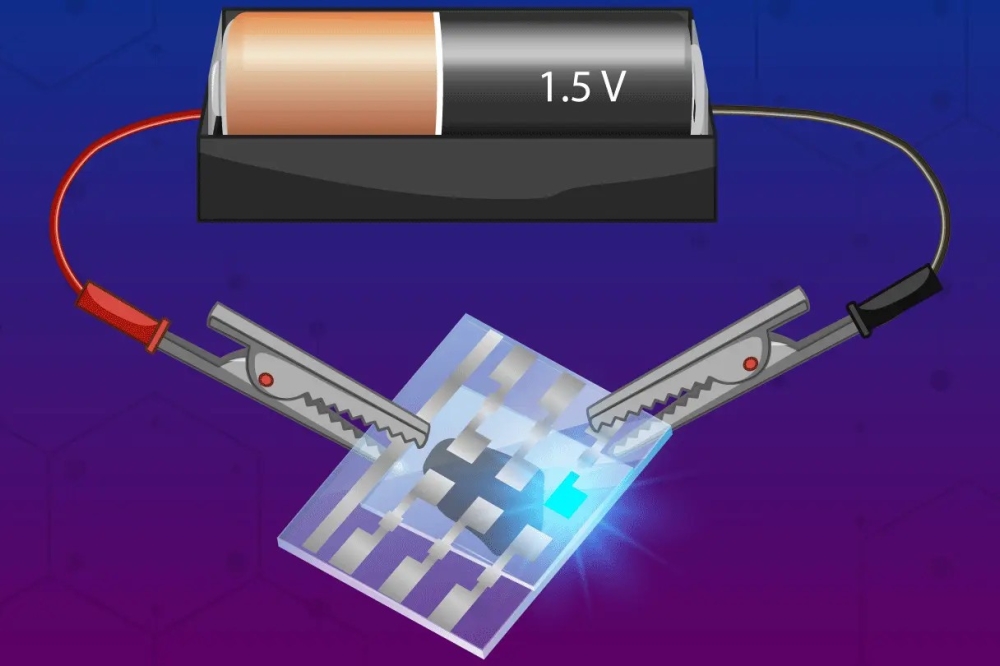

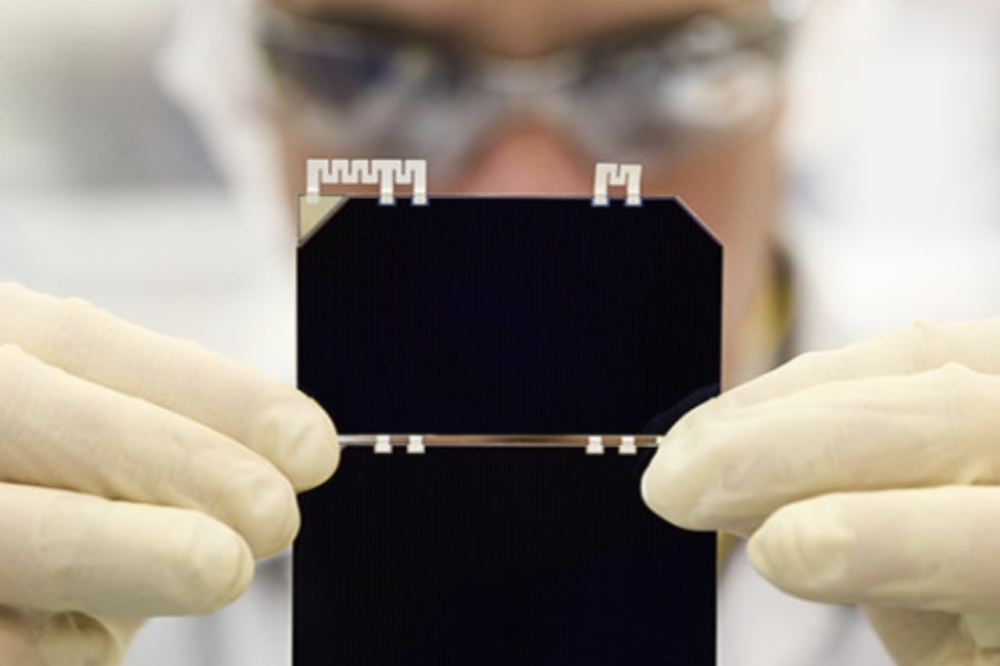

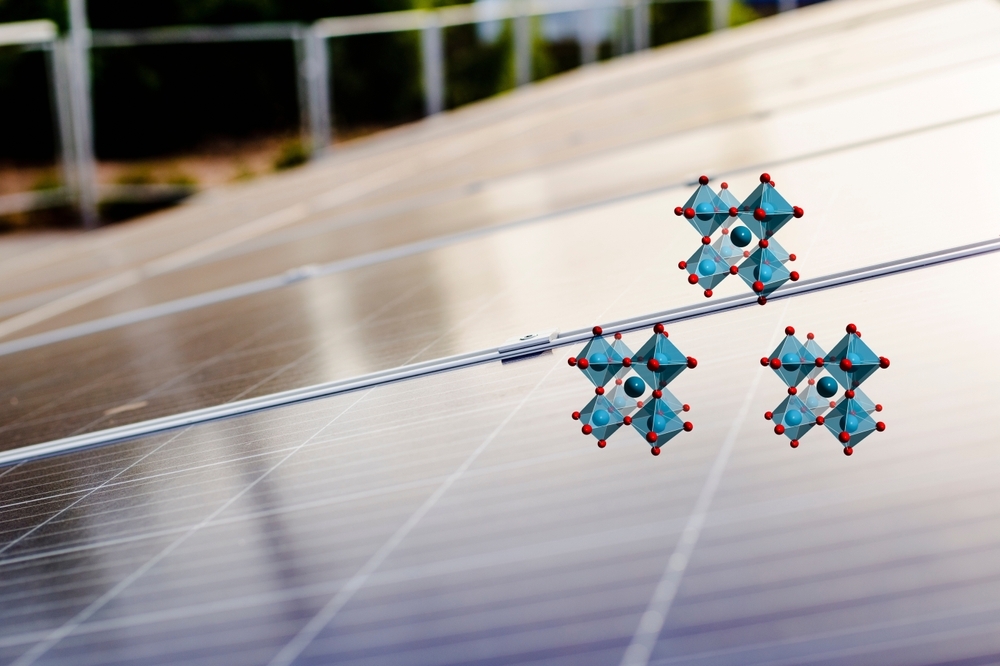

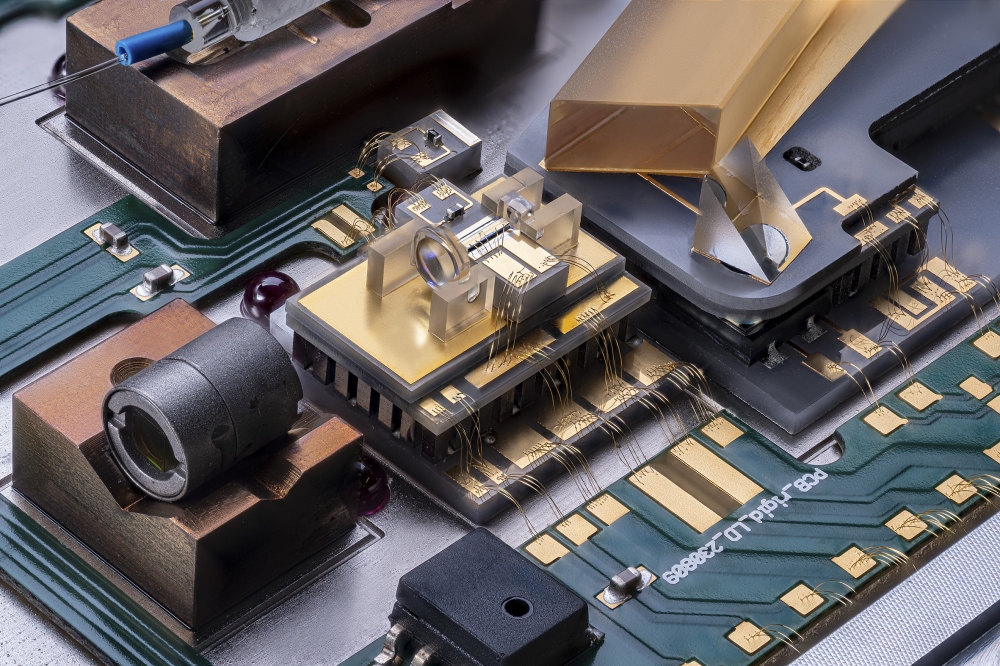

With concentrator photovoltaics (CPV) becoming an economically attractive PV technology for regions with high direct solar irradiance, the Fraunhofer Institute for Solar Energy Systems ISE and Soltec have partnered to develop a low cost prototype module.

The two-axis tracker is designed to smoothly integrate with Fraunhofer ISE’s latest micro-CPV technology. Soltec and Fraunhofer ISE plan to install a first prototype in Spain by the end of 2024.

Fraunhofer ISE has a long history in research on III-V and concentrator photovoltaics. The latest micro-CPV technology of the institute reaches 36 percent conversion efficiency and leads to a 30 percent increase in energy yield compared to conventional PV solutions. Soltec specialises in the manufacturing of solar trackers for large-scale projects.

The collaboration aims to use the advanced solar tracker technology of Soltec and adapt it specifically to the requirements of a new generation of Fraunhofer ISE’s micro-CPV modules which operate at a concentration of nearly 1000 suns. The micro-CPV modules place stringent requirements on tracking accuracy along two axes since they must always point exactly to the sun throughout the day in order to achieve the maximum electricity generation.

"We are preparing the path for the reentry of high-concentration photovoltaics into the market by offering a competitive product which shall convince investors with its high energy yield, robustness and sustainability.” said Frank Dimroth, department head of III-V and Concentrator Photovoltaics at Fraunhofer ISE.

“Resource efficiency is becoming an increasingly important topic in photovoltaics. Compared to the state-of-the-art, our micro-CPV technology reduces module areas by 30 percent and semiconductor materials by 1300 times at comparable power output. This helps to safe precious materials and energy in the production process and therefore improves sustainability.”

“This collaboration between Soltec and Fraunhofer ISE confirms the vision of both institutions. We look forward to continuing our collaboration in the future to further elevate the use of solar energy. These advancements not only represent a step forward in photovoltaic solar energy but also expand its application possibilities across various sectors,” said Eduardo de San Nicolás, chief strategy and innovation officer at Soltec.

The first prototype will be used to test the precision of tracking accuracy throughout the day. In a later stage, the system can be equipped with 15.7 kWp of micro-CPV panels.