Laser Thermal earns DARPA award

Laser Thermal, a US provider of thermal property measurement solutions, has been awarded a multi-year, multi-million-dollar Defense Advanced Research Projects Agency (DARPA) Direct to Phase II Small Business Innovation Research (SBIR) in collaboration with academic and commercial partners.

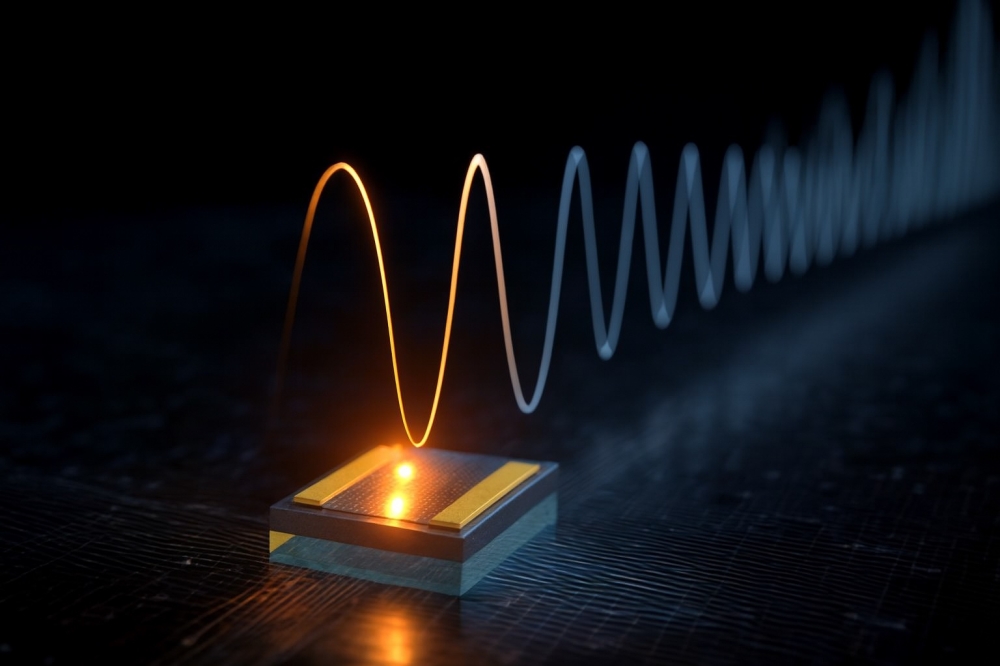

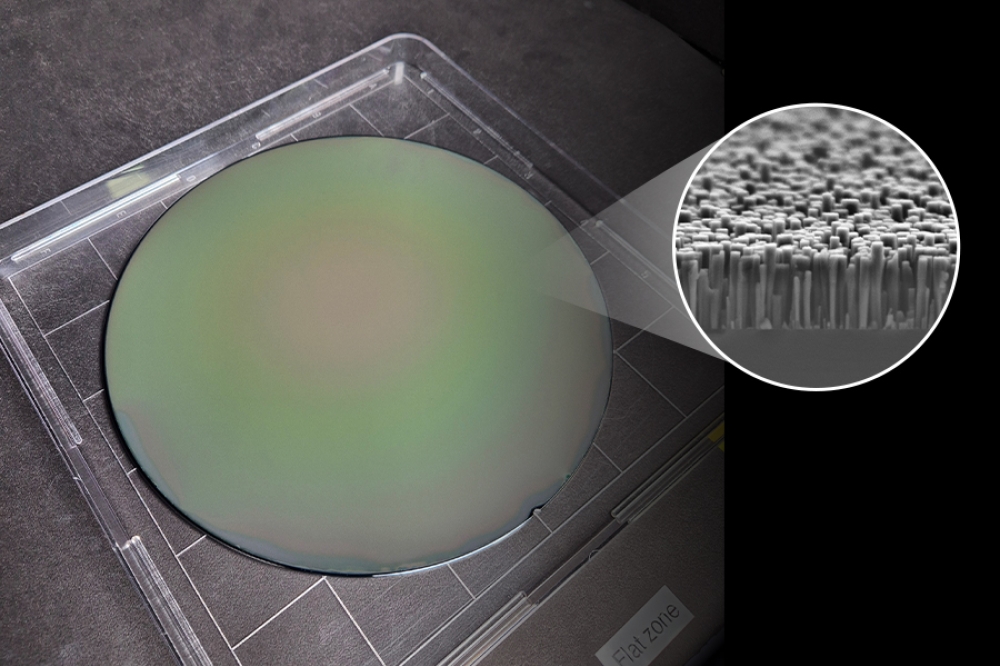

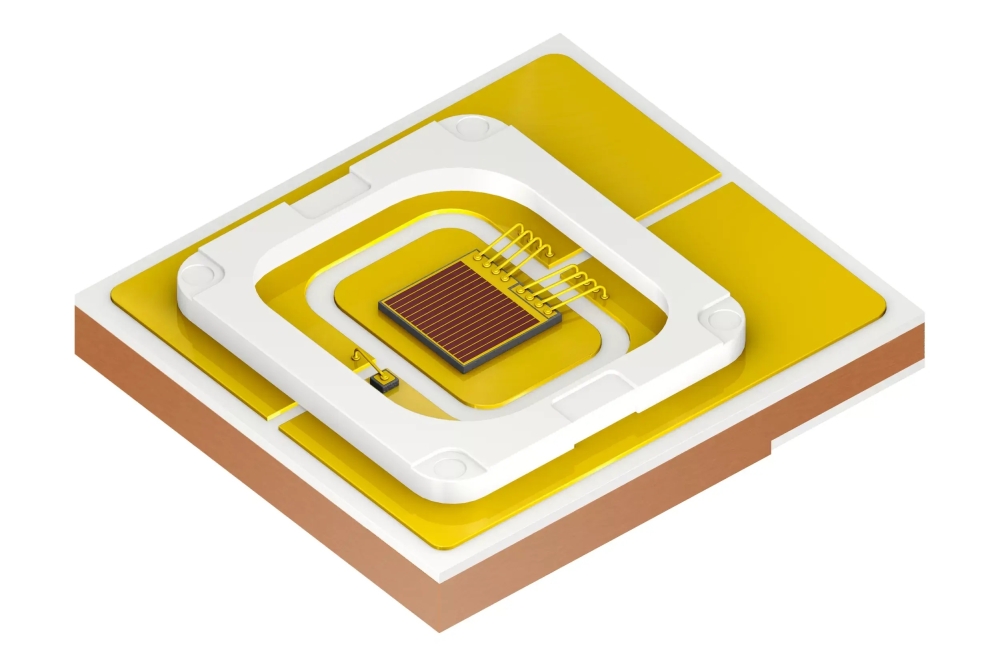

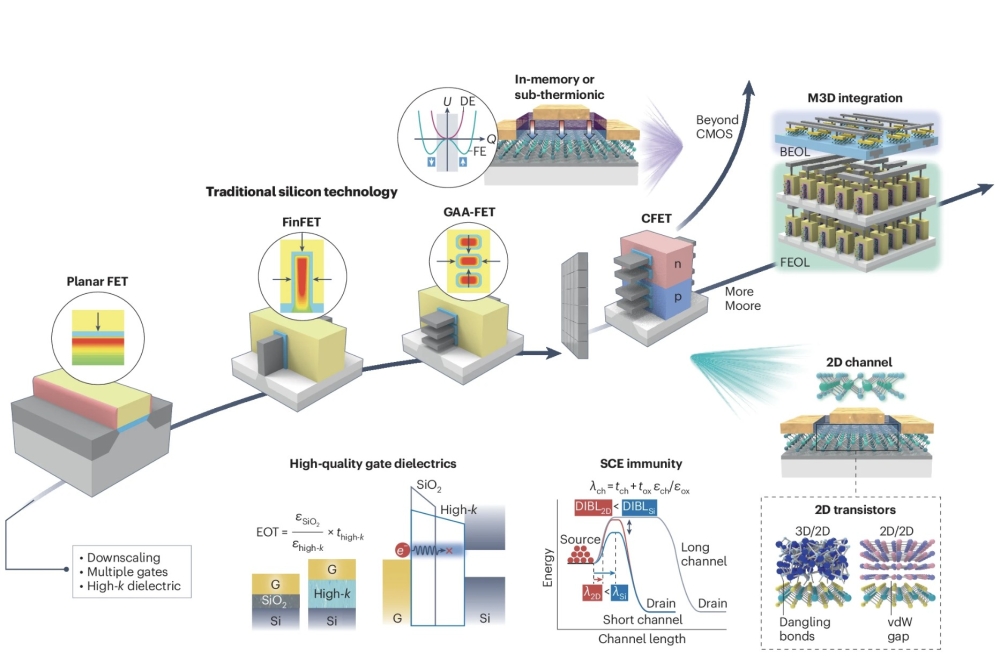

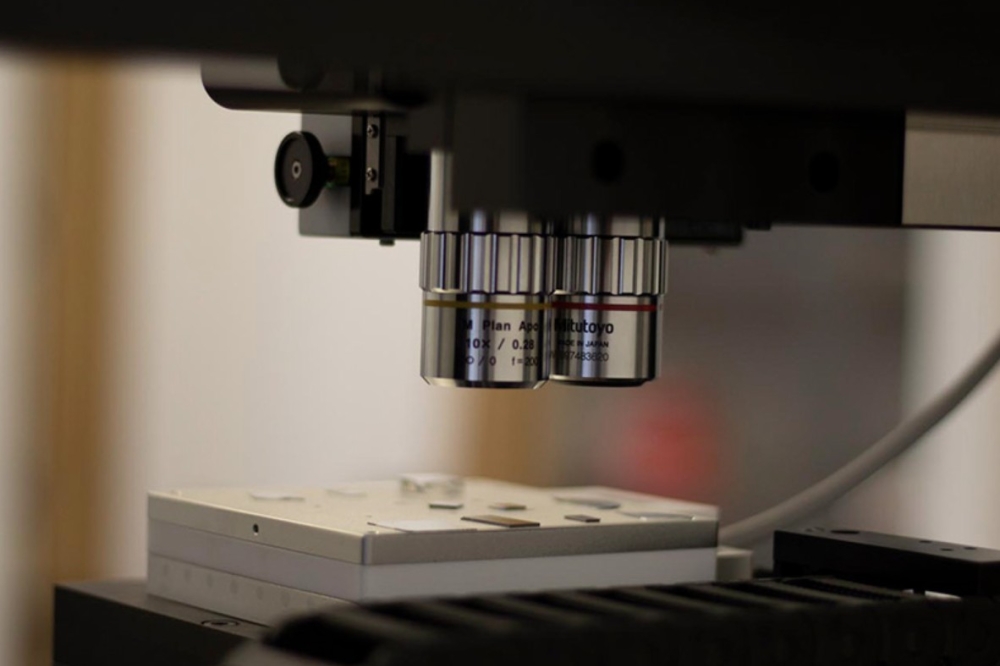

Called 'Advancing Thermo-Optical Metrology for Integrated Circuits (ATOMIC)', the company aims to further advance a super-resolution thermal metrology tool. This tool aims to characterise the thermal resistance and/or temperature of semiconductor materials/heterostructures and wide/ultra-wide bandgap RF devices at the nanometer length scale.

Brian Foley, principal investigator for the program and VP of R&D at Laser Thermal, expressed the significance of this Phase II award, stating, "This is a crucial leap forward in innovative thermal measurement techniques, combining the spatial resolution of scanning probe platforms with the sensitivity of thermoreflectance methods. We are enthusiastic about partnering with DARPA and contributing our expertise in thermal sciences to the development of state-of-the-art thermo-optical metrology instrumentation."

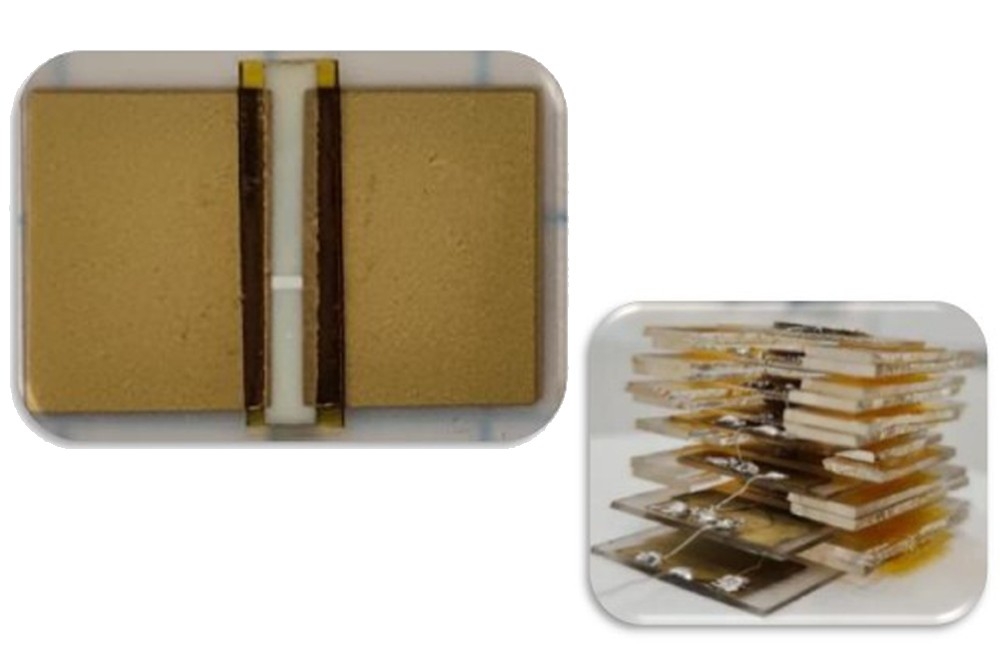

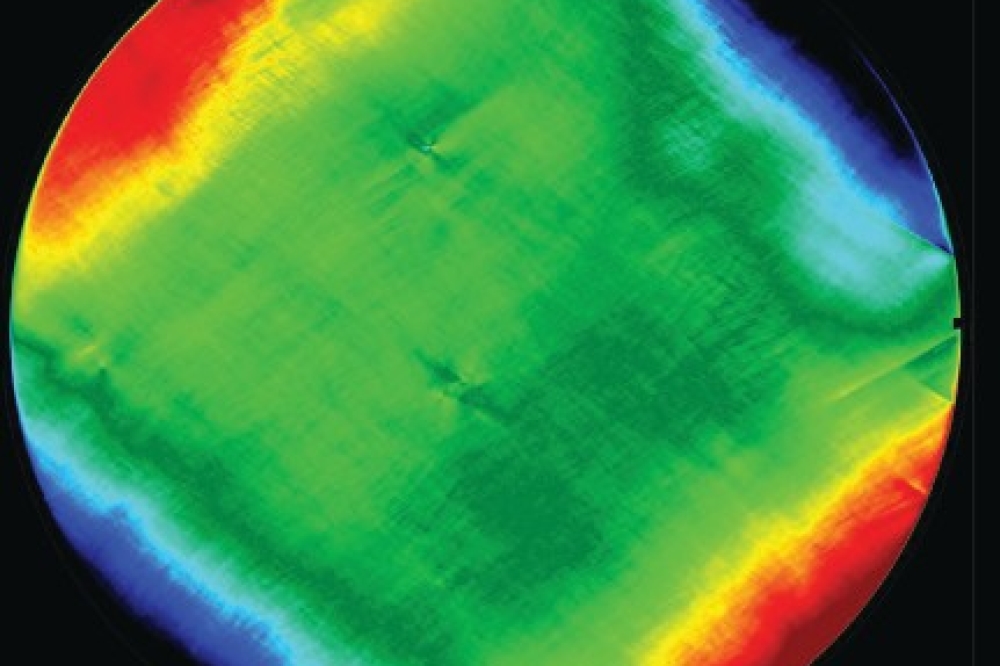

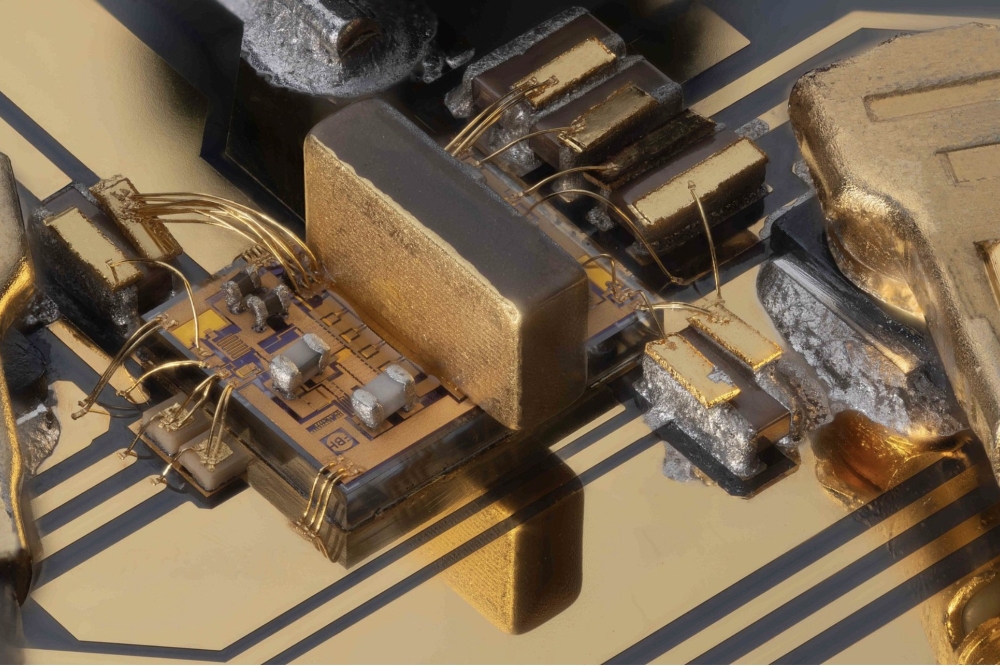

The Direct to Phase II ATOMIC program builds upon the utilisation of a thermoreflectance-based, contact-mode scanning probe platform for thermal metrology, achieving sub-50 nm spatial resolution with unparalleled sensitivity to nanoscale thermal properties. The capabilities and operating ranges of Laser Thermal's Nano-probe Thermoreflectance Microscope are being expanded and optimised through this program to further its capabilities for measuring materials integrated within functional RF HEMT device architectures.