Finwave and GF partner on RF GaN-on-Si

GaN company Finwave Semiconductor has announced a strategic technology development and licensing agreement with GlobalFoundries (GF).

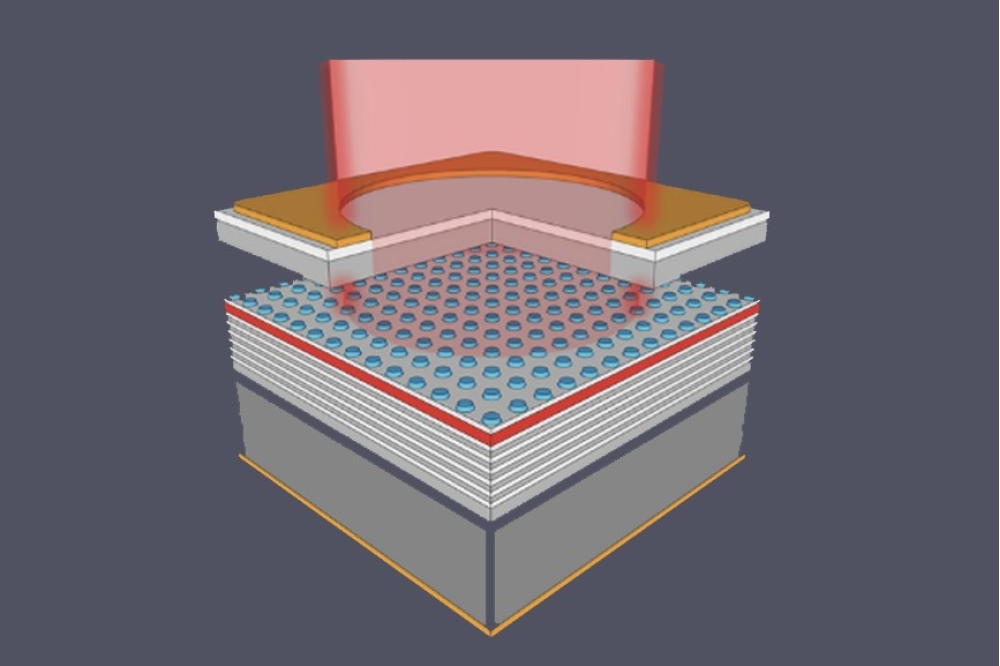

This partnership merges Finwave's RF GaN-on-Si technology with GF’s US-based high-volume manufacturing capabilities andlegacy of RF innovation including RF SOI and silicon-germanium solutions.

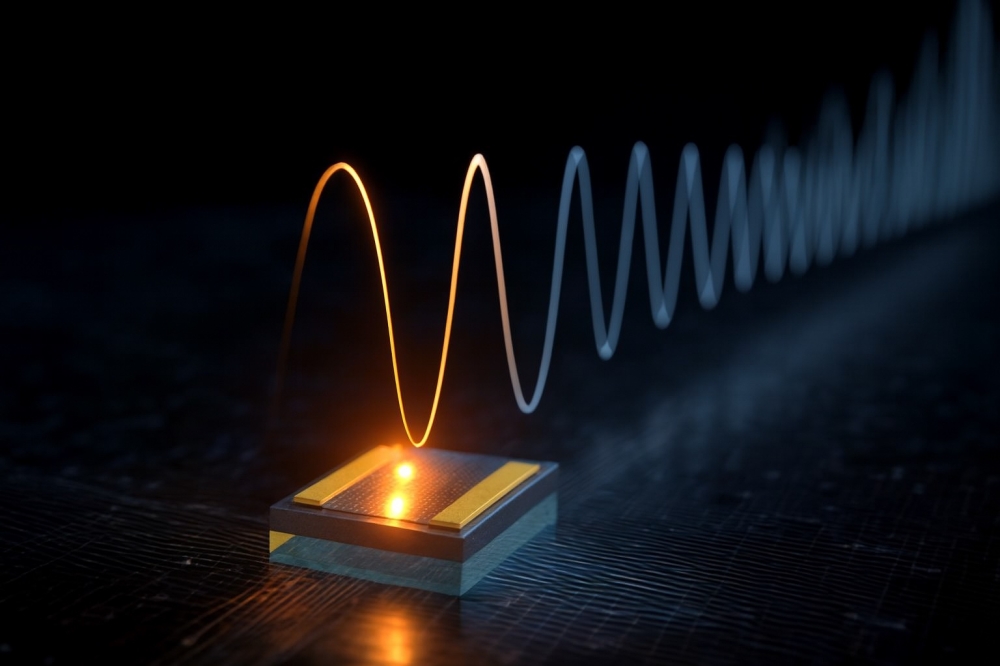

The two companies believe they can offer a solution for high-efficiency power amplifiers in applications where traditional GaAs and Si technologies fall short. This includes new higher frequency 5G FR2/FR3 bands, 6G and mmWave amplifiers, and high-power Wi-Fi 7 systems, where superior range and efficiency are critical.

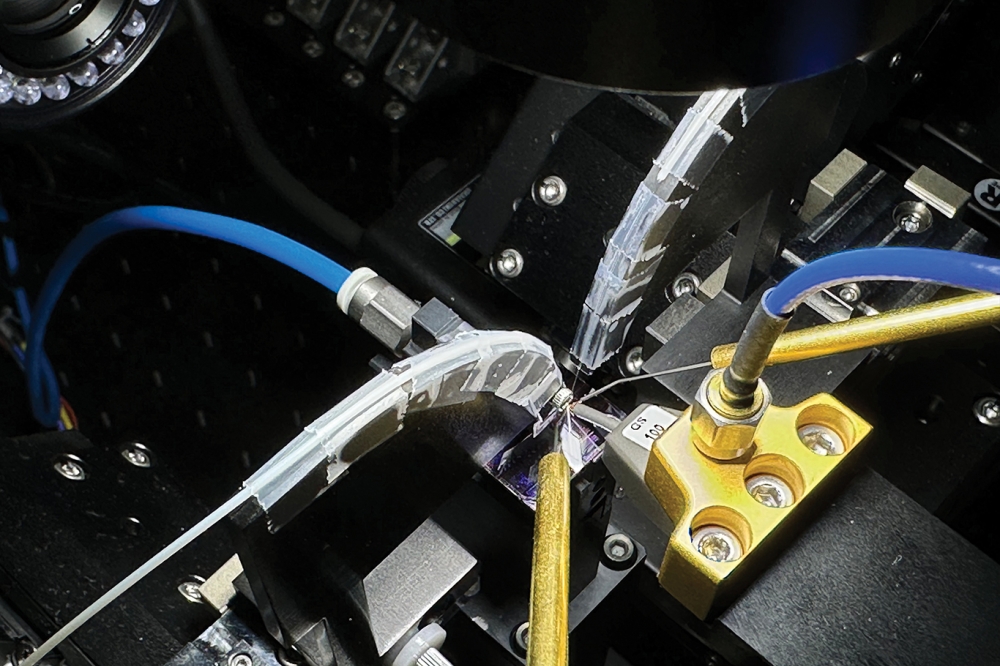

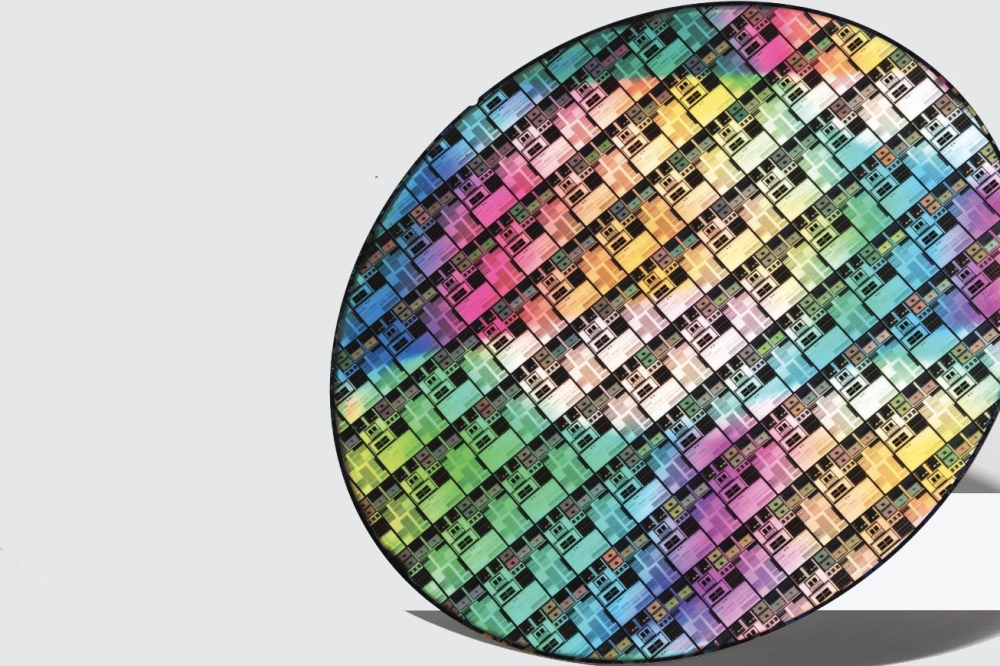

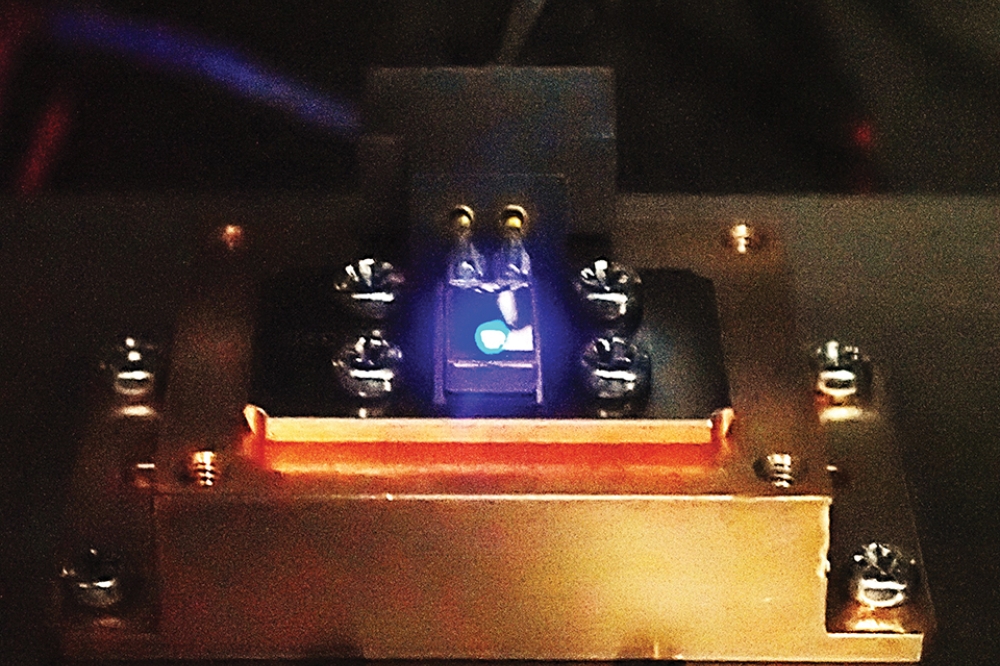

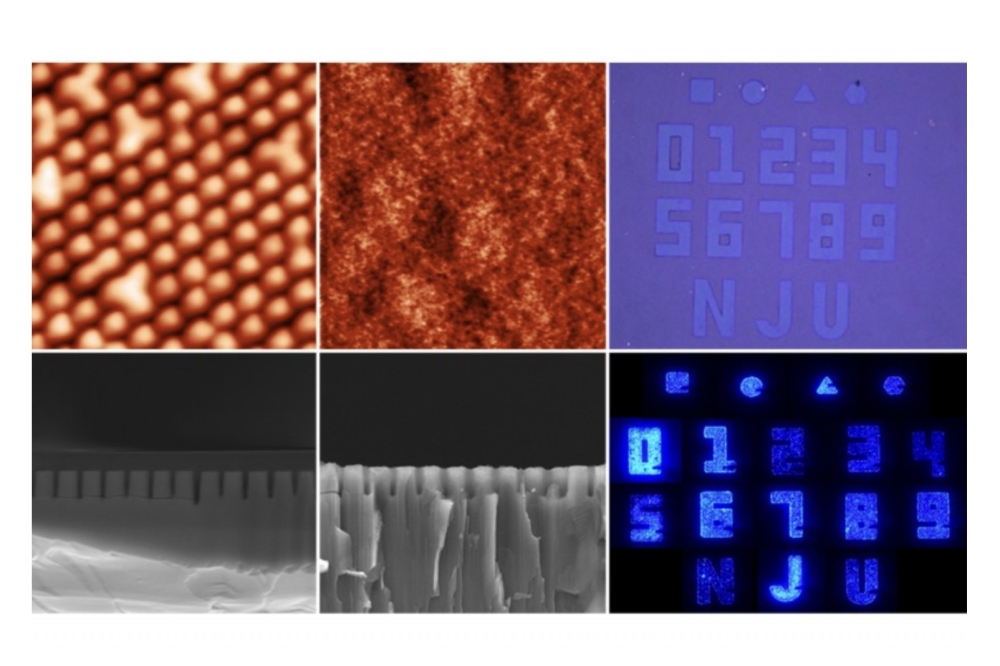

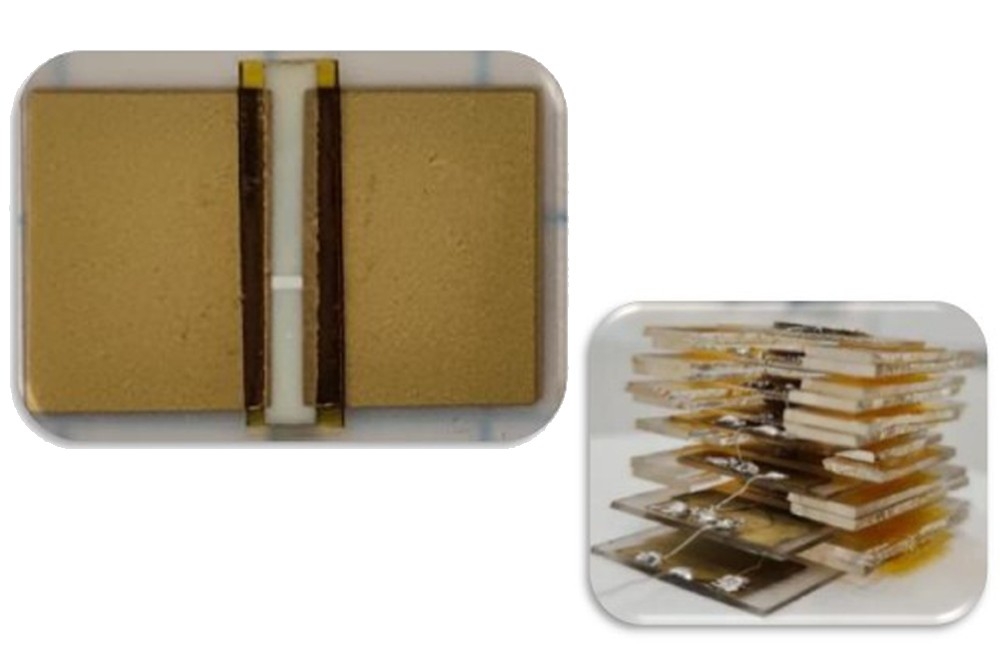

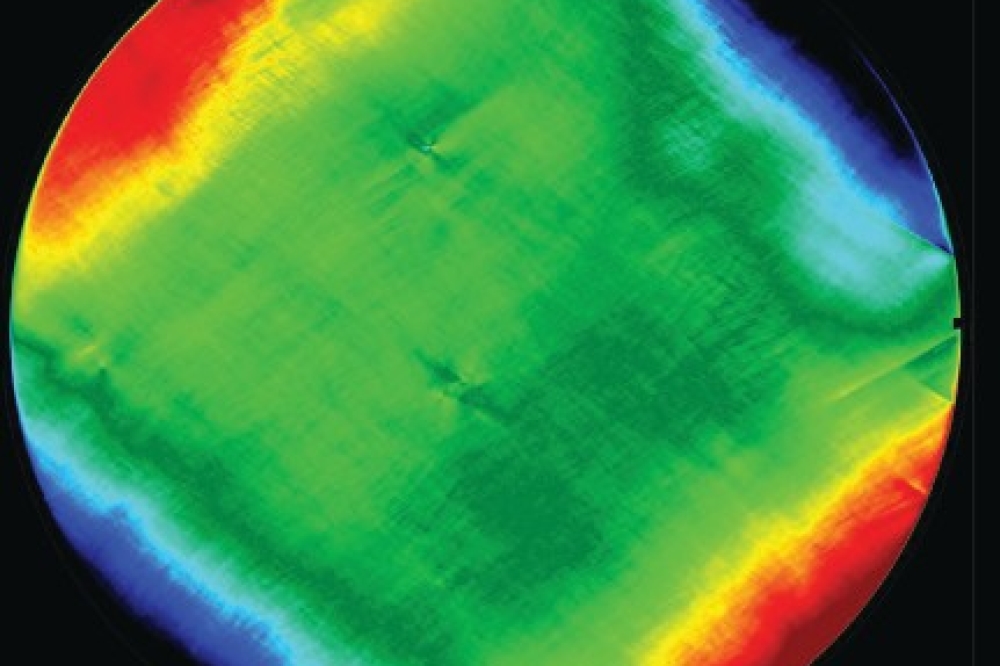

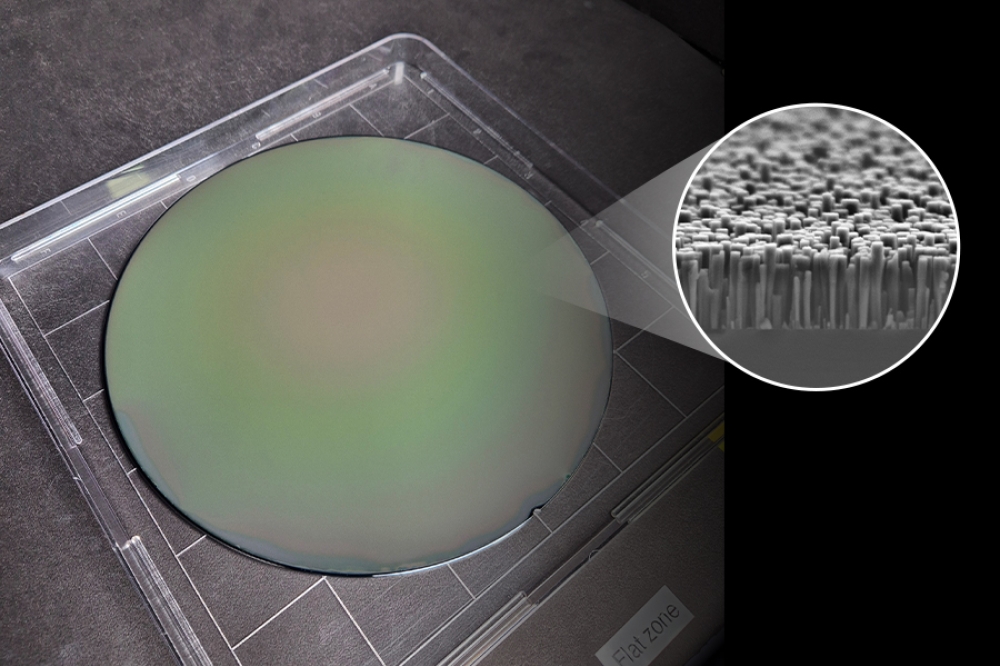

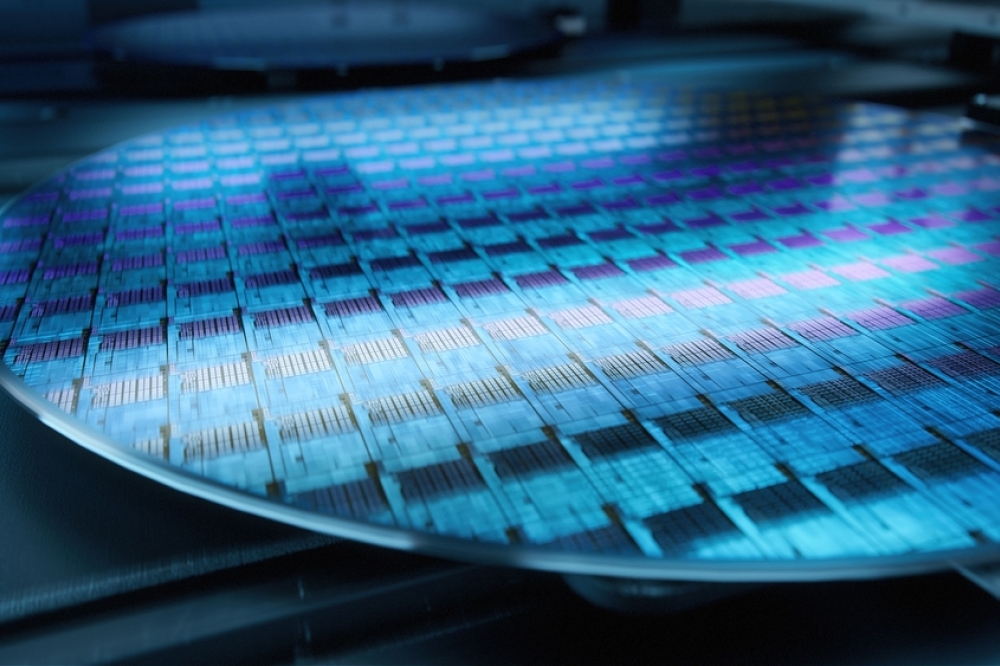

Finwave's GaN-on-Si enhacement-mode MISHEMT technology is designed to deliver high gain and efficiency at sub-5V voltages. The collaboration will focus on optimising and scaling the MISHEMT platform to volume production at GF’s 200mm semiconductor manufacturing facility in Burlington, Vermont, using GF’s 90RFGaN process.

“This agreement marks a significant milestone for Finwave,” said Finwave Semiconductor CEO Pierre-Yves Lesaicherre. “By leveraging GlobalFoundries’ extensive manufacturing capabilities and bringing Finwave’s E-mode MISHEMT technology breakthrough to volume production, we are unlocking large growth opportunities as we address the increasingly demanding wireless communication landscape. This partnership opens the door to further innovation and integration of RF Front-Ends onto a single GaN-on-Si device. This has never been done before, and has the potential to reduce cost and size, both of which are at a premium in cellphones.”

“As next-generation wireless networks require devices that operate at higher frequencies, Finwave’s low-voltage GaN-on-Si technology combined with GF’s 90RFGaN platform will become a vital part of power amplifiers in future mobile phones, ensuring both robust performance and high-power efficiency,” said Shankaran Janardhanan, VP and general manager of GF’s RF Business.

Finwave and GlobalFoundries aim to qualify this technology for mass production in the first half of 2026.