Simon Hart joins QPT as board advisor

QPT, a UK specialist in developing next generation GaN-based motor drives, has appointed Simon Hart as an advisor to its board. He is an Honorary Associate Professor and Entrepreneur in Residence at the University of Nottingham, and holds roles at several technology companies.

Rupert Baines, QPT’s CEO commented, “Simon is an excellent addition to our team as he brings a wealth of experience in scaling up businesses to exploit innovative technologies. He also has first-hand experience with electric motors drive platforms from when he was at Emerson Industrial Automation and automotive power management, which is a key area for us, when he was at YASA. He is also very hands at innovative problem solving with more than forty patents to his name.”

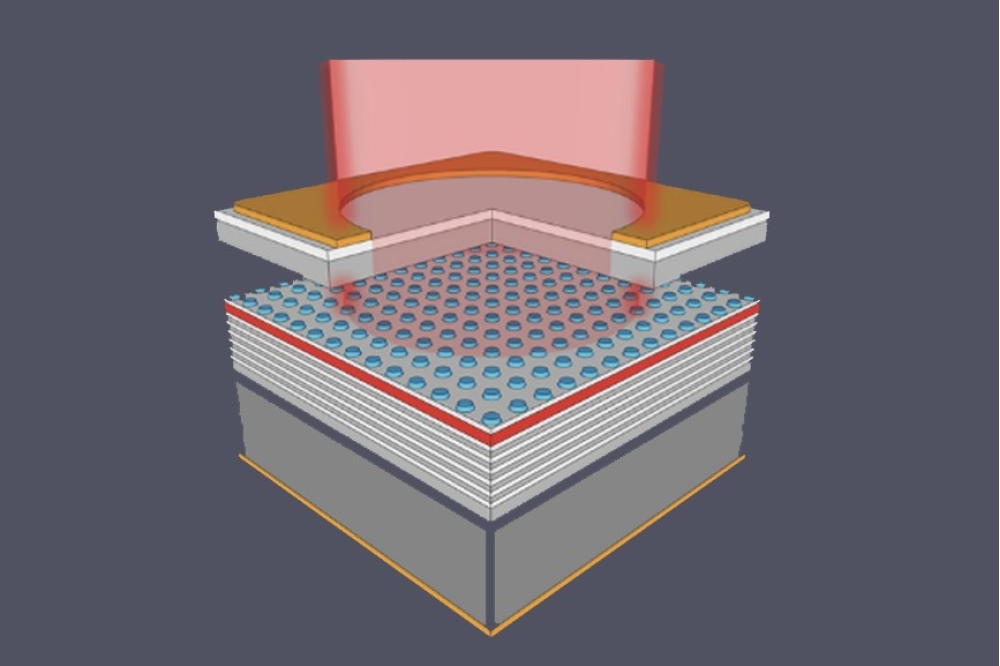

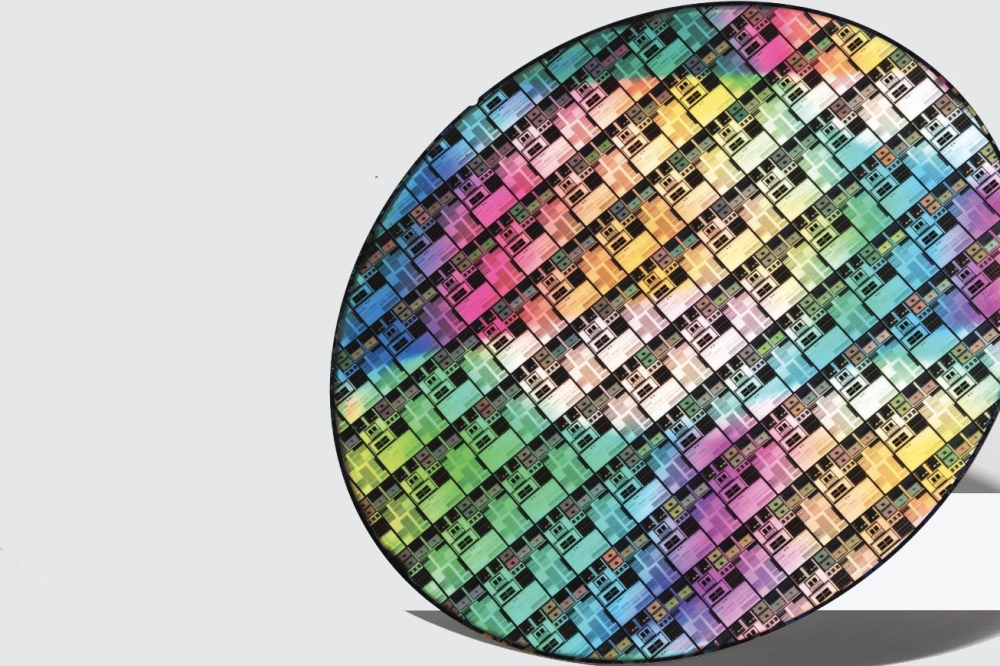

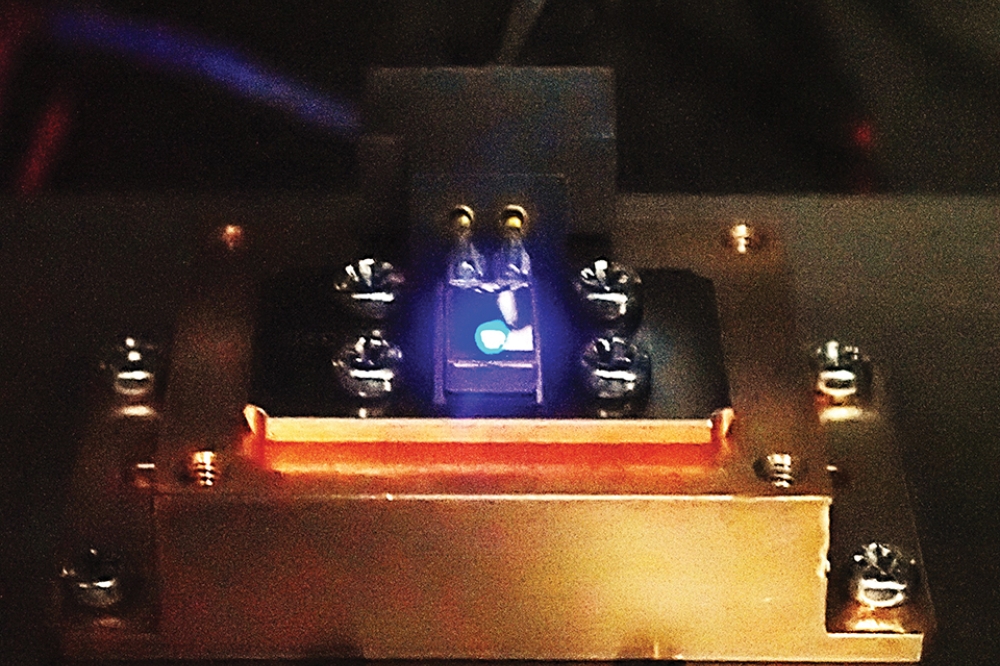

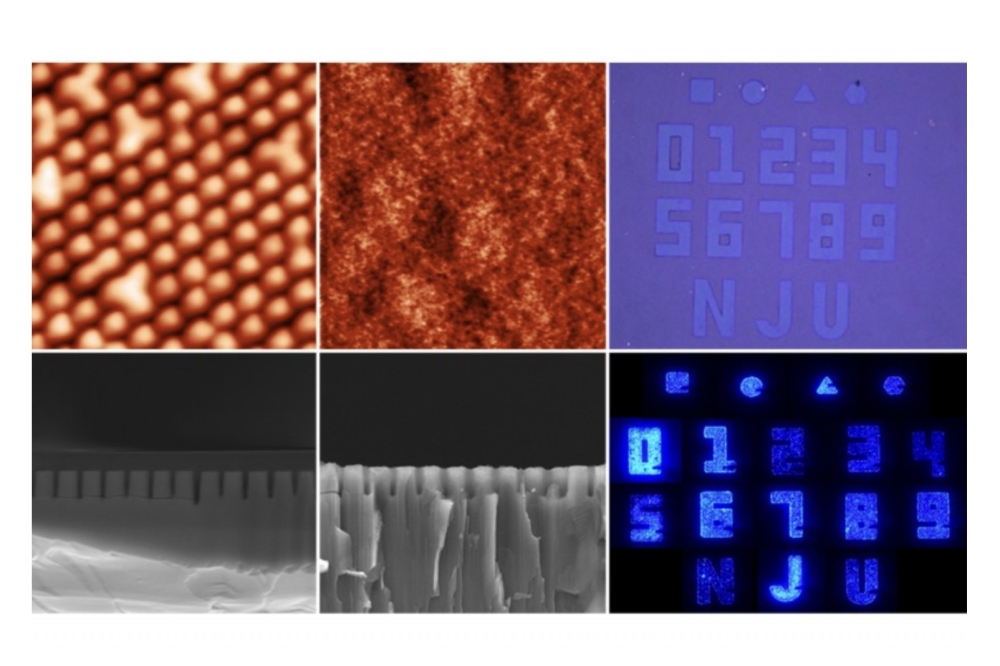

Hart, added: “Nothing excites me more than finding out about a British innovation and then helping the company on its journey to bring that to the world. Although GaN offers huge potential, QPT identified issues with GaN devices, including thermal management and production of RF interference, which is why SiC is seen by the Power Electronics Industry as the way forward for power electronics. SiC, in reality, only gives a very short switching frequency range (to around 100KHz) before it hits similar problems, and this limit is related to harmonic losses in electric motors.

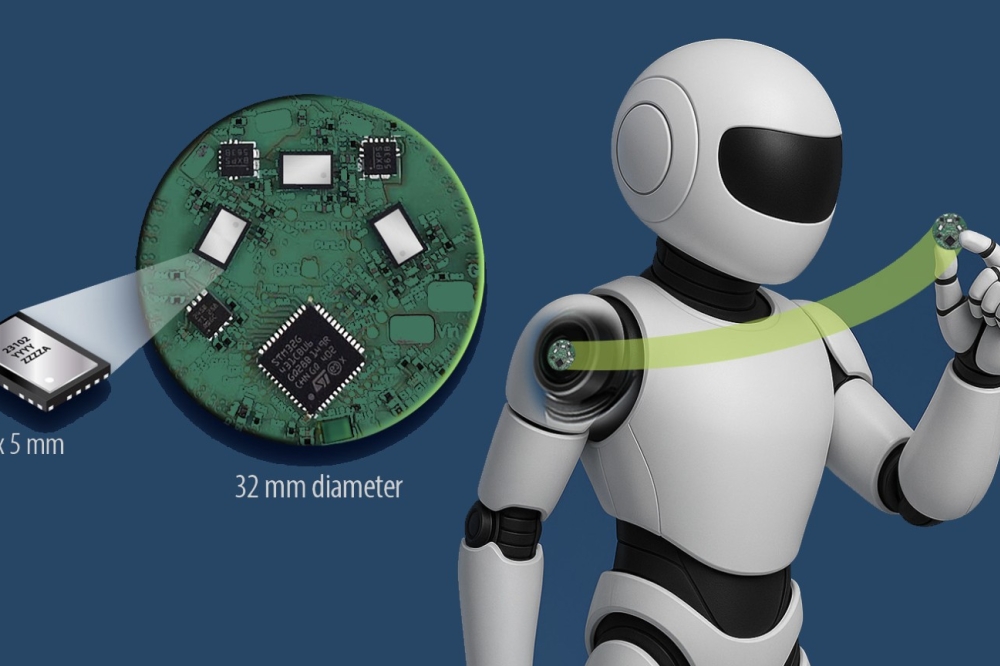

“The GaN issues are rooted in driving GaN at microwave frequencies, so QPT solved these problems by bringing microwave solutions to power electronics. Their qGaN technology enables GaN to be viable with a huge switching frequency range (1MHz or more) so it can deliver important power savings, for example slashing electric motor VFD electronics losses by up to 80 percent. This can make a huge impact on reducing the power usage of electric motors which are an increasingly significant contributor to CO2 production and therefore climate change.”