Deposition method enables 'soft' displays

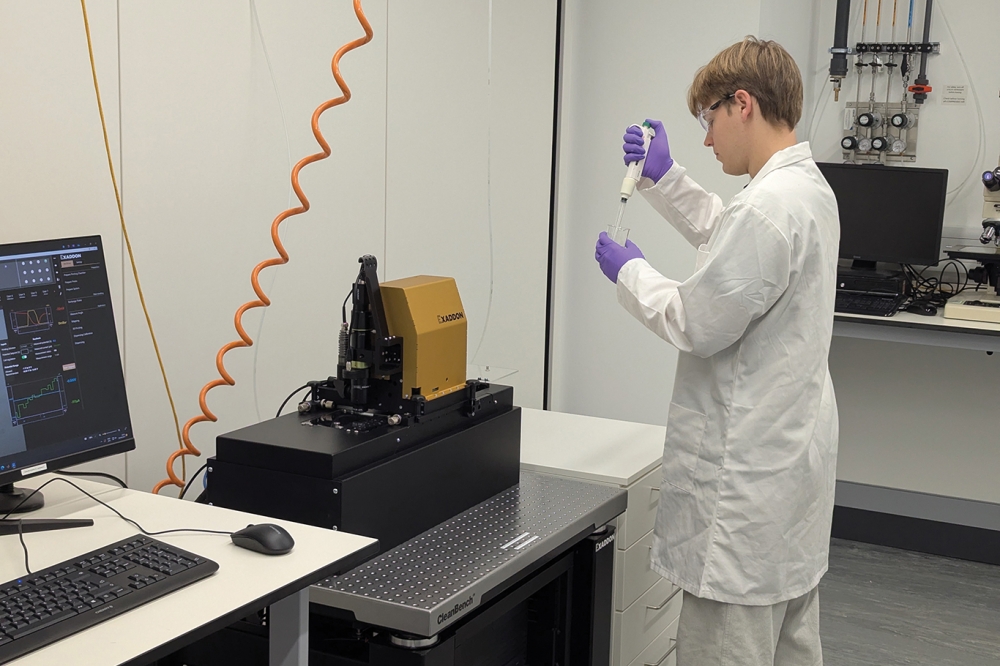

Researchers from the Seoul National University (SNU) in collaboration with the Daegu Gyeongbuk Institute of Science and Technology (DGIST), have developed a printing-based selective metal film deposition technique for quickly fabricating soft electronic devices and circuits in various forms.

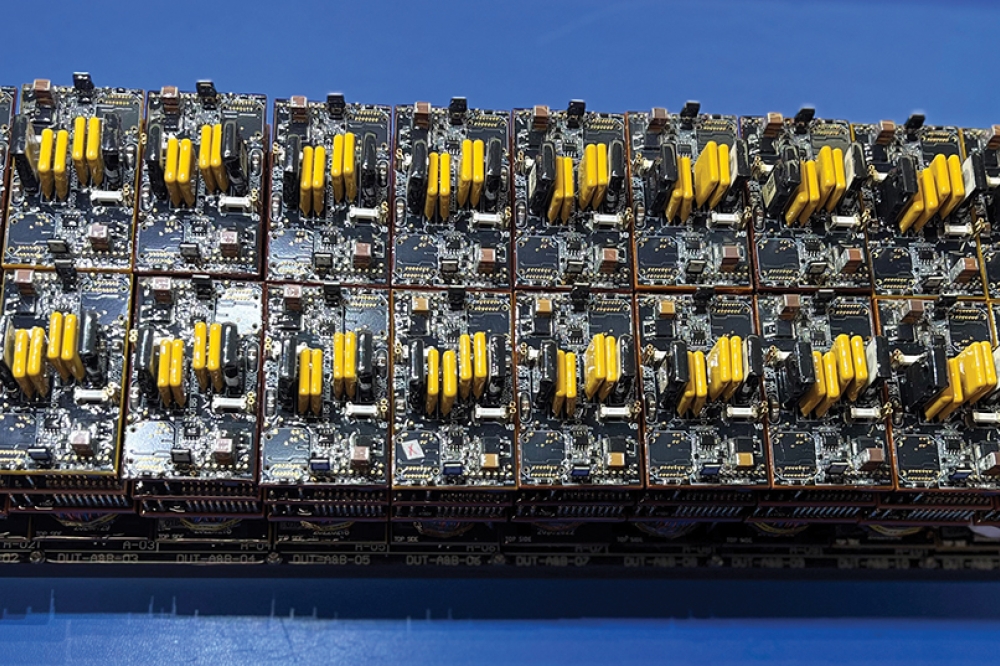

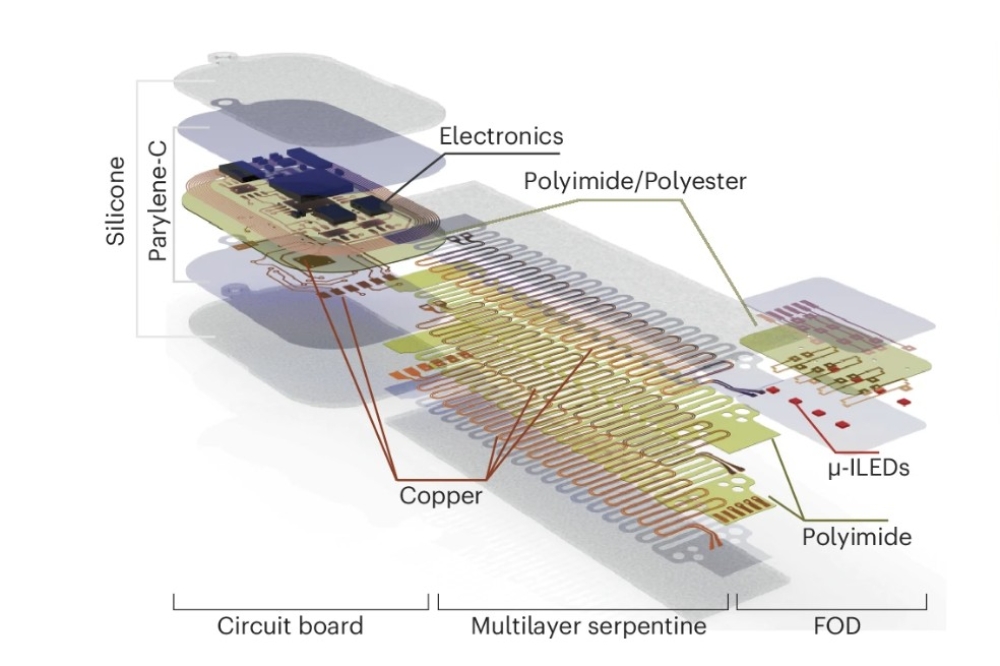

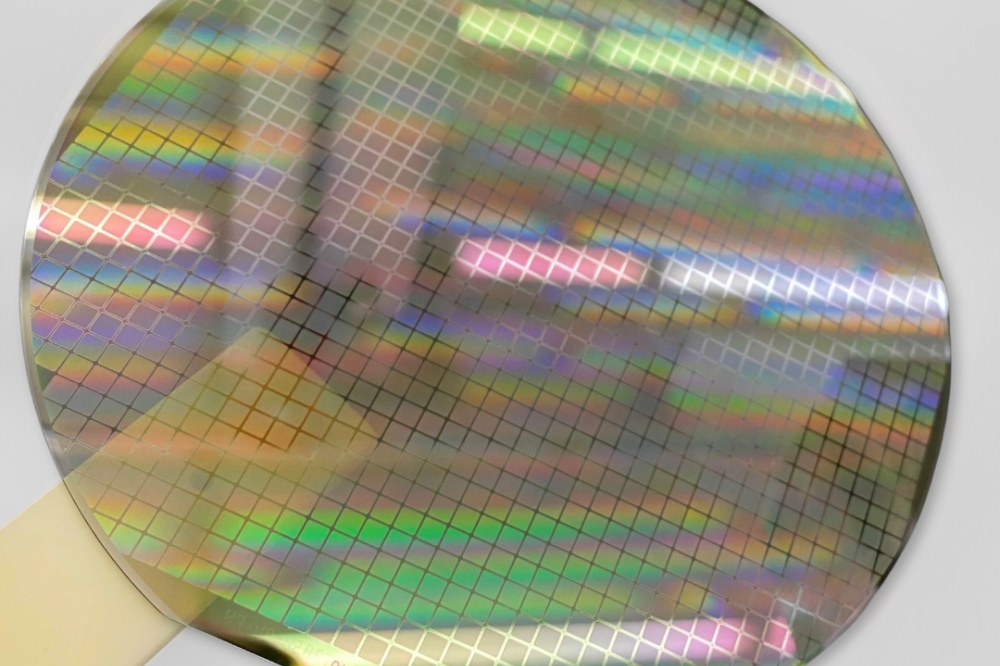

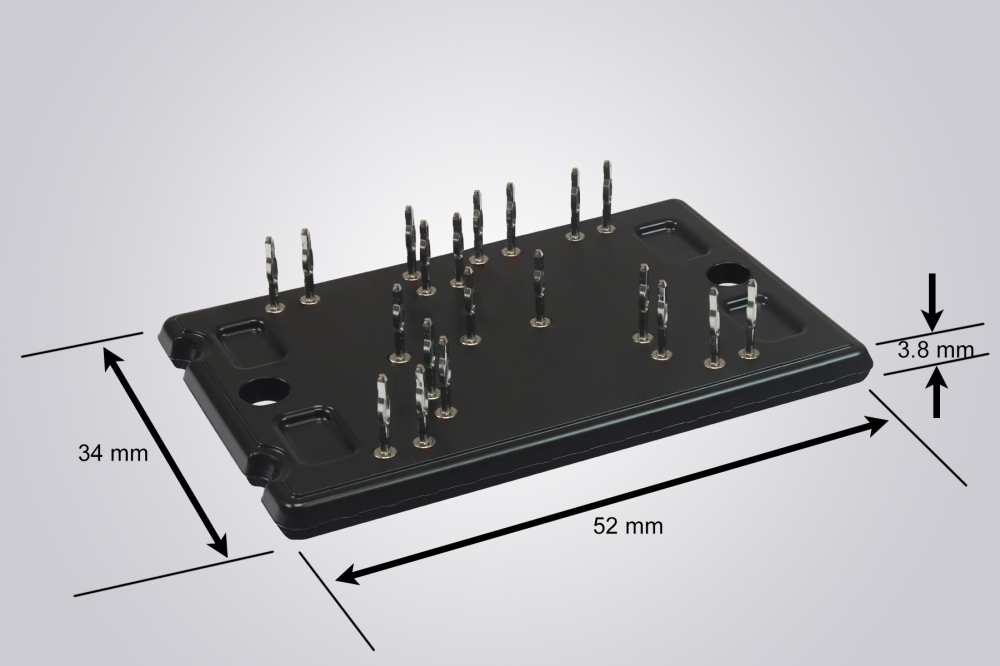

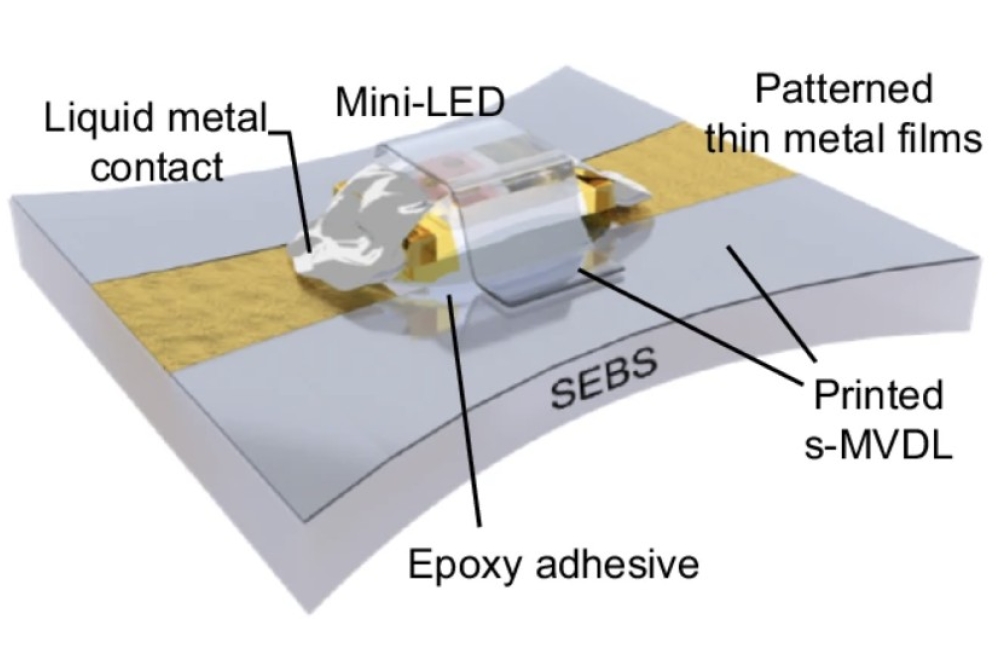

During the research, the team demonstrated wireless power transmission, curvilinear OLEDs, and stretchable LED arrays. Pictured above is a schematic illustration of the stretchable LED structure, on a styrene-ethylene-butylene-styrene (SEBS) deformable substrate.

The results were published on the 22nd of August in Nature Communications,.

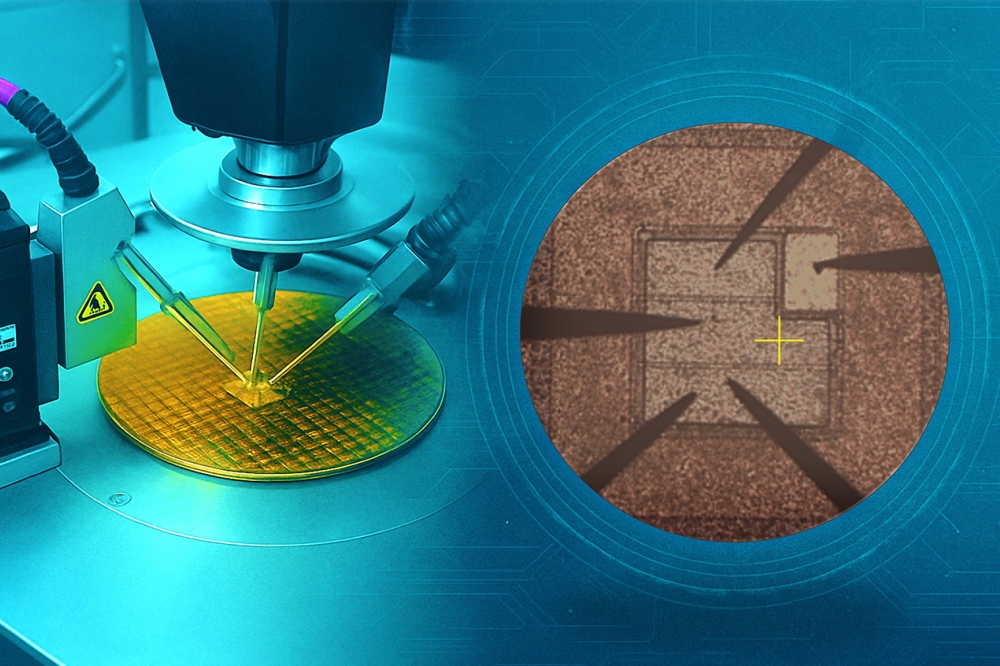

Metal thin films formed using vapour deposition have excellent electrical conductivity and surface quality. however, patterning these films into desired shapes typically requires the use of rigid masks such as shadow masks or photomasks.

To address this issue, the research team developed a printing method using polymer patterns to block the condensation of metal vapour, allowing the vapour deposition and patterning processes to be performed at the same time without the need for a separate mask.

This approach enables the production of patterns with line widths ranging from micrometers (μm) to millimetres (mm) on a large scale.

According to the research team, the polymer pattern’s excellent stretchability and mechanical durability allow metal thin film patterns to be easily formed on multi-curvature or elastic substrates, which were previously impossible with conventional methods.

SNU's Yongtaek Hong, who led the research with DGIST's Byeongmoon Lee, said: “This study not only developed a technology for easily custom-fabricating high-performance metal thin film patterns based on vapour deposition, but also set the stage for maximising the utility of metal thin films in the field of soft electronics by applying this technology to curved and stretchable systems.”

He added, “In the future, this selective metal thin film deposition technology is expected to be directly applied to forming porous transparent structures in the top common electrode of OLED panels, a key element for under-display camera and under-display face recognition sensor technologies that require various form factors.”

Meanwhile, Sujin Jeong and Hyungsoo Yoon, co-first authors of the paper, are currently working at Samsung Display Research Center, focusing on the development of next-generation future displays, including stretchable displays. The research was supported by the Ministry of Science and ICT.